J3 DentaJet gives labs productivity boost for implantology, crowns & bridges and orthodontics applications in a compact footprint

J3 DentaJet gives labs productivity boost for implantology, crowns & bridges and orthodontics applications in a compact footprint

New 3D Printer set to be unveiled live at IDS in Cologne, March 14-18

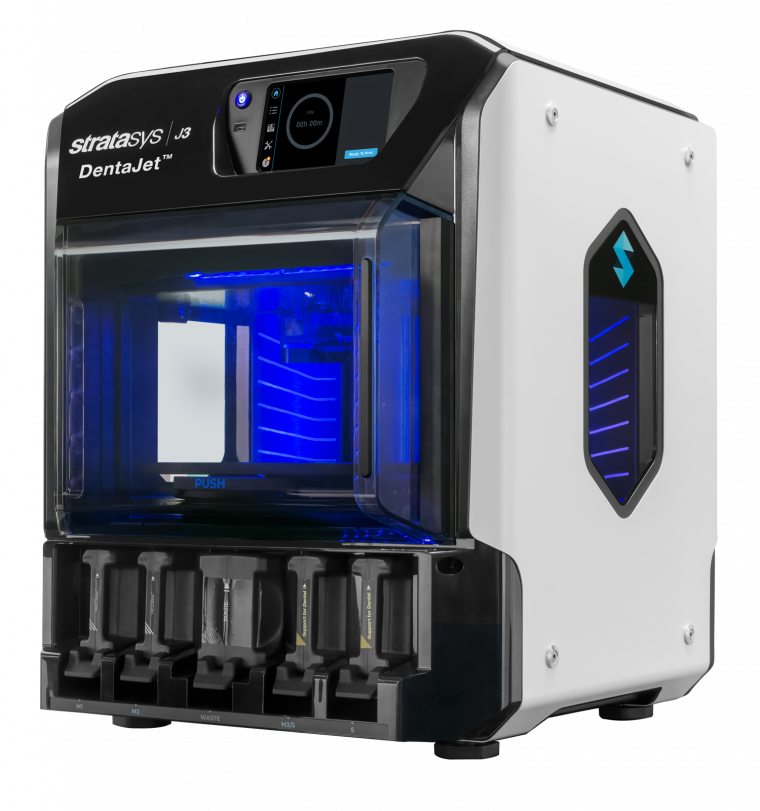

Stratasys Ltd. (NASDAQ: SSYS), a leader in polymer 3D printing, today introduced the J3™ DentaJet® 3D printer, an entry-level, multi-material printer that enables dental labs to produce extremely accurate mixed applications in a single tray simultaneously.

The J3 DentaJet will make its European premiere at the upcoming IDS global trade fair in Cologne, Germany, March 14-18. The new printer is set to be showcased amongst Stratasys’ existing range of leading dental solutions (Stand H051, Hall 10.2), including the J5™ DentaJet® and Origin® One Dental.

“This printer is a great value for smaller dental labs that have previously been limited to small, single-material, table-top 3D printers and are ready to level up their dental production to offer higher-quality digital dental products,” said Ronen Lebi, Vice President of Dental at Stratasys. “Adding a J3 DentaJet 3D printer can help labs produce best-in-class dental applications that require extreme accuracy at scale as demand is growing.”

The J3 DentaJet 3D printer features biocompatible resins (clear, rigid, and flexible) and can create mixed parts for crown and bridge models, implantology (model, surgical guides, and gingiva masks), and orthodontic models, all in the same print job. Its large circular build tray and High-Speed mode can help labs to scale and boost output. PolyJet™, Stratasys’ proprietary jetting technology, cures the printed parts during the print process, minimizing post processing. As a result, lab personnel no longer need to handle uncured resin, improving workplace safety.

“We find PolyJet to be the best available technology for printing surgical guides, especially ones that require complex geometries such as stackable guides. Other technologies just can’t achieve the same level of precision and accuracy.” said Ilan Sapir, Manager, Digital Treatment Planner, Glidewell Dental. “The J3 DentaJet enabled us to access the most advanced printing technology, packaged in a small footprint with a large print capacity.”

The J3 DentaJet joins Stratasys’ suite of dental-specific 3D printers that can all be operated and managed through GrabCAD Print™, Stratasys’ intuitive software for streamlining print preparation workflow. Stratasys is already accepting orders for the printer, which is expected to ship in March.

www.stratasys.com