The Challenge

The Challenge

Digital Aerolus has been working together with Fast Radius to find innovative solutions for the different parts of the Aertos 130IR, an industrial drone that operates in confined spaces. During the manufacturing process, Fast Radius had to face some challenges regarding the housing of the device, which needed to have certain specifications regarding the transparency of the piece.

Additive Manufacturing Can Compete with Casting on Cost Alone

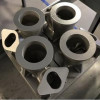

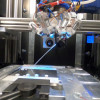

Additive Manufacturing Can Compete with Casting on Cost Alone In a joint project, Safran Landing Systems and SLM Solutions tested Selective Laser Melting to produce a component of a nose landing gear for a bizjet. A world first for a part of this size.

In a joint project, Safran Landing Systems and SLM Solutions tested Selective Laser Melting to produce a component of a nose landing gear for a bizjet. A world first for a part of this size. Installation of Stratasys 3D printers at Senior Aerospace BWT used in robust, repeatable and traceable production process for aerospace.

Installation of Stratasys 3D printers at Senior Aerospace BWT used in robust, repeatable and traceable production process for aerospace. First-ever, advanced metal 3D-printing system of its kind dedicated to flight-critical applications

First-ever, advanced metal 3D-printing system of its kind dedicated to flight-critical applications Additive manufacturing will help keep aging engines operational with greater flexibility and shorter delivery times than traditional MRO supply chains

Additive manufacturing will help keep aging engines operational with greater flexibility and shorter delivery times than traditional MRO supply chains Stratasys announced it has been awarded a contract extension for production of 3D printed polymer cabin interior components. While the initial contract with Stratasys was focused on production parts for the A350, this contract extension expands the range of parts printed for Airbus to include replacement and spare parts for maintenance, repair, and overhaul (MRO) as well as parts for aircraft platforms (such as A300, A330, A340 and A320) in addition to the A350. Stratasys is proud to continue to build on our long term relationship with Airbus as a technology, material, and part supplier.

Stratasys announced it has been awarded a contract extension for production of 3D printed polymer cabin interior components. While the initial contract with Stratasys was focused on production parts for the A350, this contract extension expands the range of parts printed for Airbus to include replacement and spare parts for maintenance, repair, and overhaul (MRO) as well as parts for aircraft platforms (such as A300, A330, A340 and A320) in addition to the A350. Stratasys is proud to continue to build on our long term relationship with Airbus as a technology, material, and part supplier. Spacecrafts are developed, tested and fully assembled on Earth and transported in one piece by a launch vehicle to their respective places of operation. Each component must be able to withstand the extreme conditions during the launch phase. In most cases, in addition to complex test procedures, this leads to an oversized structure of the spacecraft components, because in orbit they experience only a fraction of the stresses they must endure during rocket launch.

Spacecrafts are developed, tested and fully assembled on Earth and transported in one piece by a launch vehicle to their respective places of operation. Each component must be able to withstand the extreme conditions during the launch phase. In most cases, in addition to complex test procedures, this leads to an oversized structure of the spacecraft components, because in orbit they experience only a fraction of the stresses they must endure during rocket launch. Strong, lightweight, ABS-based material is specifically formulated for applications such as manufacturing tooling, jigs and fixtures

Strong, lightweight, ABS-based material is specifically formulated for applications such as manufacturing tooling, jigs and fixtures Challenging titanium parts for XB-1 demonstrator aircraft successfully 3D printed on VELO3D’s Sapphire system

Challenging titanium parts for XB-1 demonstrator aircraft successfully 3D printed on VELO3D’s Sapphire system From design to test flight in six months after close collaboration GE Additive’s AddWorks team, the GA-ASI team launched a test flight of its MQ-9B SkyGuardian, the first remotely piloted aircraft (RPA) with a metal printed part, its NACA inlet.

From design to test flight in six months after close collaboration GE Additive’s AddWorks team, the GA-ASI team launched a test flight of its MQ-9B SkyGuardian, the first remotely piloted aircraft (RPA) with a metal printed part, its NACA inlet.