HP’s portfolio of 3D printing solutions – prototyping and production, plastics and metals – is seeing strong customer adoption across numerous industries. More than 18 million parts were produced with HP Multi Jet Fusion in the last 12 months alone.

HP’s portfolio of 3D printing solutions – prototyping and production, plastics and metals – is seeing strong customer adoption across numerous industries. More than 18 million parts were produced with HP Multi Jet Fusion in the last 12 months alone.

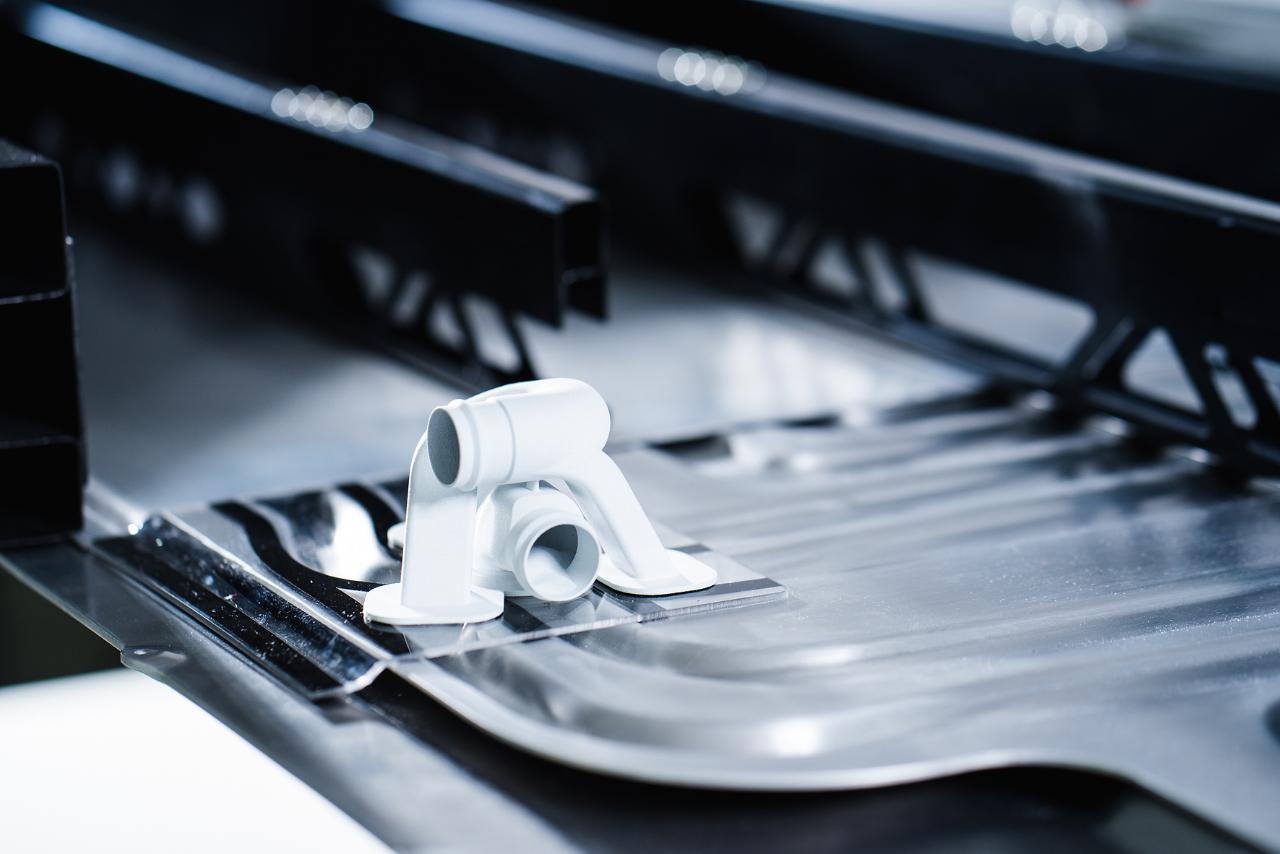

Earlier this year, HP launched the Jet Fusion 5200 Series 3D solution, its most advanced plastics solution to date. Avid, a product development firm specializing in manufacturing efficiency, Weerg, a rapidly growing manufacturing parts provider, Yazaki, a global automotive parts supplier and wire harnessing specialist, and Extol, an engineering and parts producer for the automotive and other industries, are among early users achieving improved operational efficiency and greater productivity.

“HP is providing so much more than a 3D printer, they have truly delivered a full solution for volume final parts production,” said Doug Collins, Founder and Co-Owner, Avid Product Development. “Our ability to use the new hardware, data, software, and services to improve all aspects of our operational productivity and efficiency along with the innovative features and new materials like TPU has brought tremendous value to Avid and our customers.”

Last year Volkswagen Group selected HP Metal Jet as the foundation for its strategy to industrialize additive manufacturing. Volkswagen and HP are executing a multi-year design and production roadmap and recently crossed an important milestone. In partnership with GKN Powder Metallurgy, the companies completed a production run of more than 10,000 high quality parts produced in just a few weeks to support the visionary ID.3 electric vehicle launch event.

www.hp.com