HP Jet Fusion 3D Printers accelerate the production of smart eyewear for efficient maintenance and repair of industrial equipment

HP Jet Fusion 3D Printers accelerate the production of smart eyewear for efficient maintenance and repair of industrial equipment

Viewpointsystem GmbH uses 3D printing with HP Jet Fusion printers for product development and production. The Austrian start-up company's latest product is the VPS 19 Smart Glasses - eye tracking glasses that connect employees at different locations almost as if they were working together on site and in the same room.

The VPS 19 Smart Glasses are a practical and cost-efficient tool for remote maintenance and inspection of machines as well as for training and documentation purposes. Compliant with EN166 safety requirements, the glasses are extremely comfortable to wear and are ideally suited for working at a distance in production and maintenance. The robust plastic frame makes them particularly light: one pair of eye-tracking glasses weighs only 43 grams

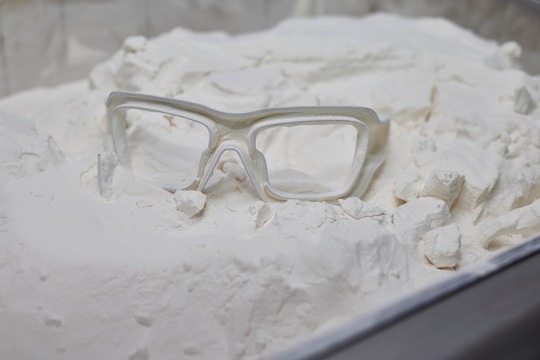

The use of HP's state-of-the-art Jet Fusion 3D printing solutions was essential for the rapid and cost-effective development of the frame. In an iterative process, the prototypes could be flexibly optimised within a very short time until the final spectacle geometry was produced. And that at a much lower cost than using traditional production methods. A flexibility that was also decisive for the decision to localise the production of the glasses in Vienna. Viewpointsystem relies on the local partner d4pro and industrial 3D printing from HP to produce its spectacle frames.

The final assembly of the Smart Glasses will take place at the company's headquarters in Vienna. The production of the spectacle frames from the 3D printer is handled by production partner d4pro directly at Viewpointsystem's production site in the technology centre in Vienna's Seestadt. For this, d4pro relies on the HP Jet Fusion 4210 3D printing solution, which also includes a processing station. The system is optimised for industrial prototype construction and component production. With the exchangeable build unit, 24/7 production operation is possible without any problems. Within a week, the plastic components for up to 400 spectacles can be produced at maximum capacity.

Smart Glasses facilitate maintenance

The heart of the Smart Glasses is the high-performance electronics developed in-house, which includes camera technology with a front camera and two eye-tracking cameras. The image data is calculated directly in the glasses. In addition, sensor data fusion takes place between the camera technology and sensors that record, for example, user behaviour and perception. This makes it possible, for example, to determine exactly which machine parts the wearer of the glasses focuses on during a repair, what he or she perceives and what he or she may not perceive. He can thus be instructed particularly precisely.

"The HP JetFusion technology has significantly accelerated the development of the optimal geometry of the glasses. The ability to mass-produce the plastic parts for our Smart Glasses quickly and cost-effectively directly at the company's site is sustainable and efficient. Within the shortest possible time and largely independent of suppliers, we can make adjustments and even customise the spectacle frames to meet individual customer requirements," says Nils Berger, CEO and owner of Viewpointsystem. "The result is Smart Glasses, which have become indispensable especially in today's remote maintenance environment".

"With its portable, cost-efficient Smart Glasses, Viewpointsystem is a pioneer in remote support solutions. Manufacturing via the 3D printing solutions, Viewpointsystem offers the possibility of scaling production capacities flexibly and at any time according to demand. The HP Jet Fusion 4200 printing solution is specifically designed for industrial prototyping and component manufacturing," said Raffi Beglarian, 3D Printing Regional Sales Manager EMEA, HP.

www.hp.com