• arburgXworld: Freeformer integrated in the digital world of Arburg

• arburgXworld: Freeformer integrated in the digital world of Arburg

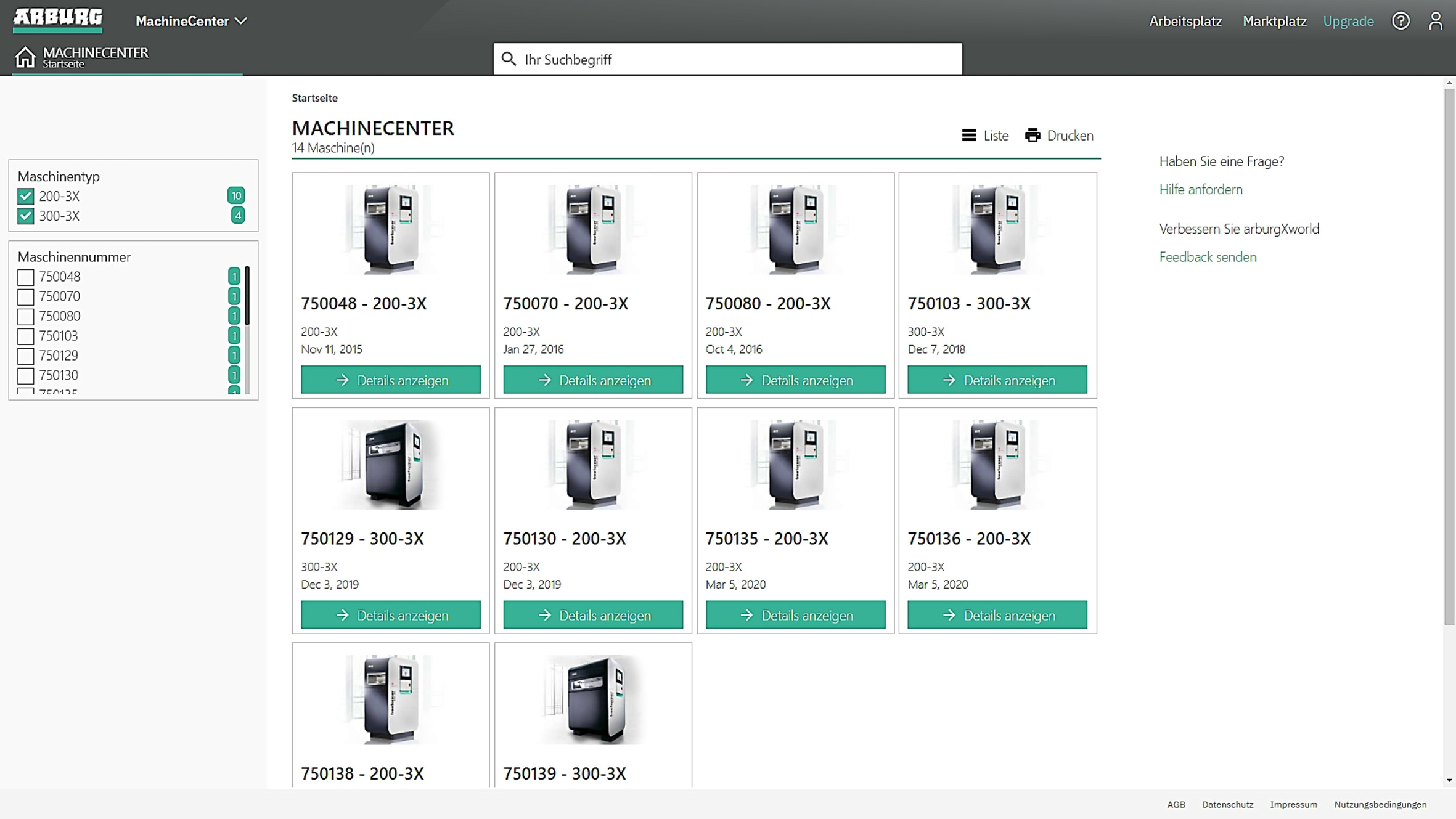

• MachineCenter: Machine- and part-specific process data, software and data sheets

• Shop: App for convenient and fast spare parts ordering

The integration of the Freeformer into the digital customer portal arburgXworld is a new feature that Arburg will be presenting for the first time at the Formnext Connect 2020. The basic version is free of charge and offers Freeformer customers significant added value.

ARBURG always regards additive manufacturing and Arburg Plastic Freeforming (APF) using the Freeformer as a process to be integrated into the overall production environment of a company. The successful and complete monitoring and documentation of the process data of APF components plays an important role in this context.

MachineCenter provides comprehensive transparency

The MachineCenter app provides transparent information on all machines and build jobs. The latest software and numerous material data sheets are available for download for every Freeformer. For this purpose, the customer portal also contains the entire material database of Arburg, which is continually being expanded. In addition to general information such as strength, each data sheet also contains the appropriate process parameters for the respective material.

Process data can be tracked with regard to parts

A further app developed specifically for the Freeformer enables process and build job data to be visualised and tracked. Information on the machine used, order start, build time, layer structure, build chamber temperature, etc. can be clearly displayed in graphic form for the entire build job. This is particularly useful if detailed documentation on the component is required. For example, in medical technology applications and in the automotive and aerospace sectors.

Order spare parts conveniently online

The shop app offers further practical features for the users of ARBURG Plastic Freeforming (APF). For example, spare parts and consumables can be ordered around the clock.