Flame resistance is an important property when using plastics in electrical engineering or in public transport. This is also becoming increasingly important for 3D printing materials, as the production of series components and spare parts is increasingly being carried out using 3D printing.

There are many different and sometimes very complex test methods for determining fire properties. Every industry has standards according to its needs. Some of the most important: UL94 for electrical engineering, FAR 25.853 for aerospace, UN-ECE R.118.03 for buses and EN 45545-2 for rail vehicles.

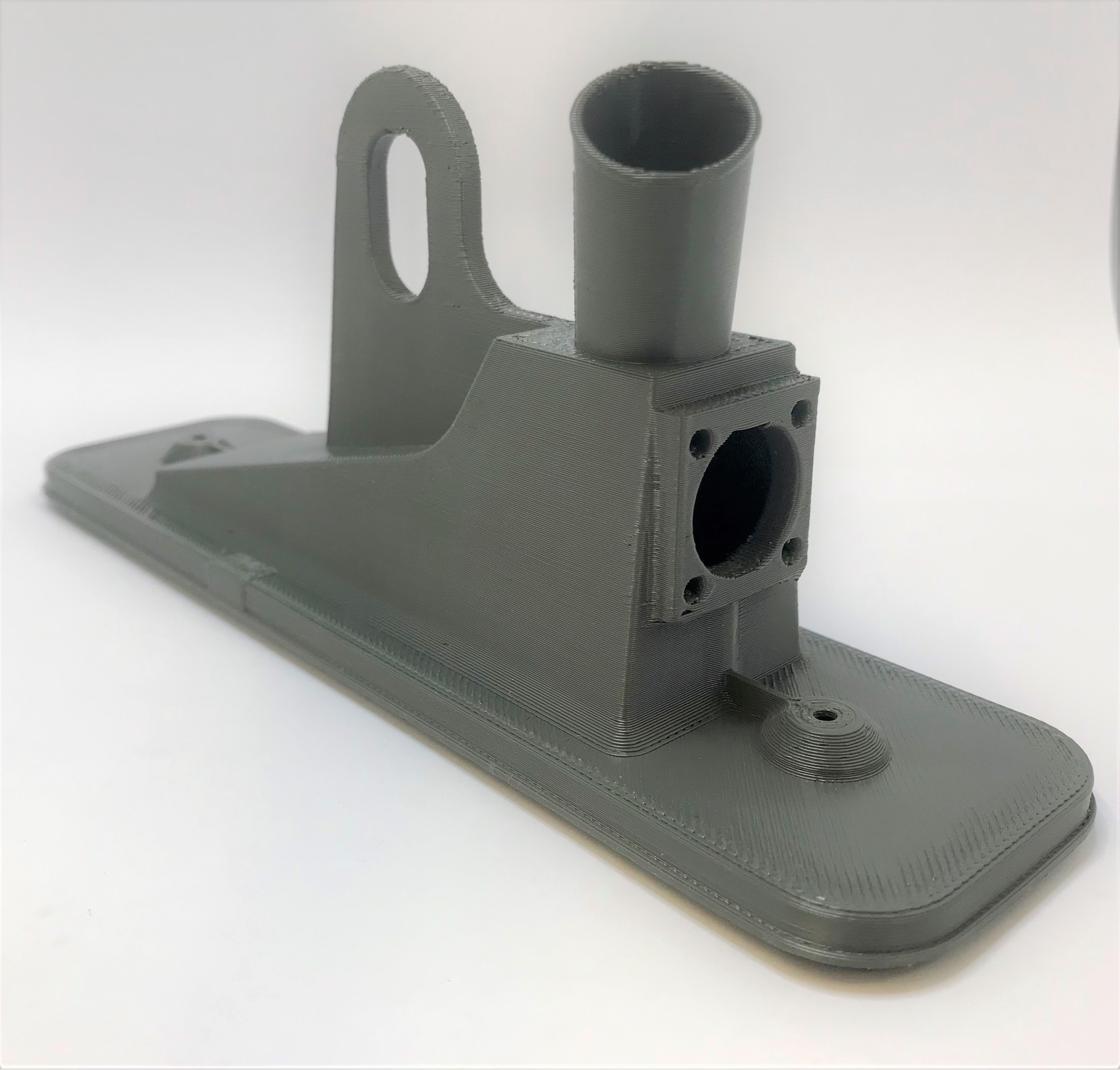

The railway industry relies primarily on the EN45545-2 standard, one of the most demanding fire testing standards in the world. LUVOCOM 3F PEI 50236 GY, based on polyetherimide (PEI), already meets the EN45545-2 R1 HL3 certification for 3D-printed samples that are only 2 mm thick. The test specimens made from LUVOCOM 3F PEI 50236 GY achieved previously unattainable test values and thus position the material as one of the best in its class for railway applications. This enables the use of 3D printed parts in sensitive applications in rail vehicles. LUVOCOM 3F PEI 50236 GY is colored grey. This eliminates the need for a primer coat on components and improves weather resistance and UV resistance.

The LEHVOSS product portfolio includes many other materials for railway applications. Examples include LUVOCOM 3F PAHT KK 50056 BK FR, based on a high-temperature polyamide (PA) and LUVOCOM 3F PPS CF 9938 BK, based on PPS. Both materials meet EN 45545 R22, R23 HL3.

All three materials mentioned also meet the UL 94 V0 test requirements, starting at just 0.4 mm on 3D-printed test components.