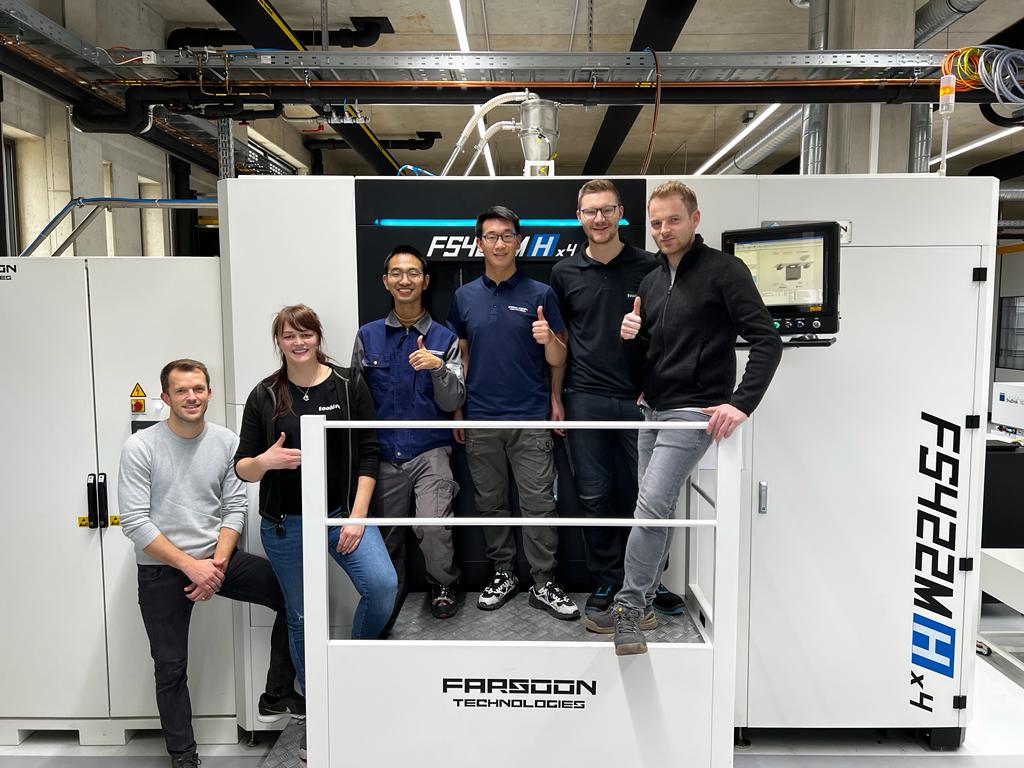

• toolcraft has started production of metal parts with the Farsoon FS422M-4 Laser- Powder-Bed-Fusion System (L-PBF) after Farsoon successfully completed installation and commissioning in Georgensgmünd.

• Farsoon and toolcraft entered into a Joint Development Agreement for optimizing hardware and software of the Farsoon FS422M-4 system and quality assurance of metal parts’ production.

After deep evaluation and benchmarking, some months ago toolcraft AG decided to order a new Laser-Powder-Bed-Fusion (L-PBF) system from Farsoon for the additive manufacturing of metal parts. Today, toolcraft can confirm that Farsoon delivered and installed the system as promised.

“I am positively impressed on the speed and professionalism of the Farsoon team installing the Laser-Powder-Bed-Fusion System in our facilities in toolcraft” said Mr. Christoph Hauck, Chief Officer Technology and Sales of toolcraft AG. “The Farsoon FS422M-4 system has passed the factory acceptance test at the first trial, and we have started production of high-quality aluminum parts for sale to our customers already.”

The Farsoon FS422M-4 is a system for Additive Manufacturing of metal parts by using metal powders and laser melting technology. The FS422M is fabricated & assembled by Farsoon Technologies Co., Ltd., Changsha, China. The FS422M-4 operates with four laser/scanning systems for high quality parts in serial production, with the build cylinder size of 425 x 425 x 550 mm3 (incl. substrate plate). The surface quality of the metal parts, for instance using aluminum powders, is especially good even at the very high speed of parts production.

“toolcraft has put Farsoon under high pressure for demanding requirements on quality of aluminum parts at lowest production costs. toolcraft today confirmed Farsoon achieving these requirements, which is highly satisfying for me” said Dr. Dirk Simon, Managing Director of Farsoon Europe GmbH. “The achieved status is very encouraging for us to collaborate with toolcraft in a development partnership to further optimize the system for the production of better metal parts at lower production costs.”

Within the collaboration the Parties, both Farsoon and toolcraft, join their forces with complimentary competences, on laser melting system hardware, auxiliary equipment. processing parameters, optimization of productivity and reducing production costs per part, Farsoon software and its integration with 3rd party quality control systems for advanced quality assurance.

www.farsoon-eu.com