Located in Ann Arbor, Michigan, APEX Dental Milling Center was one of the early adopters of CAD/CAM technology for producing dental parts straight from CAD design imagery. The company switched from outsourcing production with CNC contract machining shops to in-house 3D printing. With digital dentistry, APEX Dental Milling Center can offer lower prices and faster delivery times while maintaining its high quality standards.

Located in Ann Arbor, Michigan, APEX Dental Milling Center was one of the early adopters of CAD/CAM technology for producing dental parts straight from CAD design imagery. The company switched from outsourcing production with CNC contract machining shops to in-house 3D printing. With digital dentistry, APEX Dental Milling Center can offer lower prices and faster delivery times while maintaining its high quality standards.

The Challenge

Dental technicians traditionally rely on steady hands and expert eyes to prepare crowns, bridges, inlays, onlays, veneers and frameworks. This manual process is time-consuming and imprecise and uses materials that are often lacking in durability and aesthetic appearance.

Increasingly, dental companies now use 3D printing, whether in the dental practice or laboratory or via production centers. 3D printing provides access to new, industrially prefabricated and controlled materials; higher quality and reproducibility; data storage commensurate with a standardized chain of production; and increased productivity. APEX Dental Milling Center recognized the advantages of 3D printing and began investigating its options.

The Solution

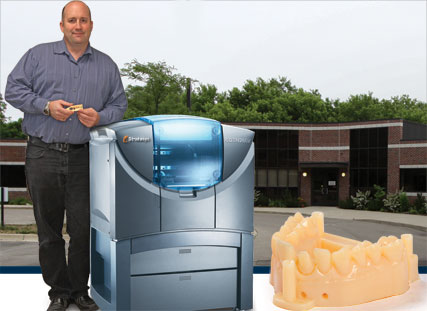

APEX selected the Objet Eden260V 3D Printer because it offers higher accuracy, superior finish and shorter processing times than the other alternatives it considered.

APEX Dental Milling Center staff quickly learned how to use the Objet 3D Printer to speed up its manufacturing workflows. Models produced on the Objet 3D Printer deliver exceptionally fine details and an outstanding surface finish. Printed models are predictable and consistent, providing a perfect fit and occlusion on the physical model.

The Value

APEX Dental Milling Center now uses a digital workflow that includes scanning, restoration and 3D model printing. The workflow takes full advantage of CAD/CAM technology to produce restorations in less time. The digital dentistry process also enables APEX Dental Milling Center to receive and process scans from major intra-oral scanners nationwide.

The high-speed manufacturing and ultra-efficient batch and multi-case processing capabilities of the Objet 3D Printer increase productivity and yield an excellent cost per-case.

"The 3D printing technology bullet train continues to accelerate the pace of change in dentistry," said Chris Brown, manager at APEX Dental Milling Center. "The day has arrived when everything from scheduling to finished restoration can be handled digitally."

"Rapid manufacturing is an affordable and attractive option for dental lab owners," Brown concluded. "With an Objet 3D Printer, APEX Dental Milling Center was able to realize a complete digital workflow for in-house fabrication of models of any size or shape. Efficient in-house manufacturing opens many new indication possibilities."