Bioprinting is changing how we do biology.

Bioprinting is changing how we do biology.

Not much has changed in the way of tissue culture since

Alexis Carrel pioneered the space over 100 years ago. We continue to use the

same dishes, and run most of our experiments on two dimensional homogenous

tissues. Unfortunately, these 2D models of biology are extremely primitive when

compared the 3D arrangements of cells in our bodies.

Over the past several decades scientists have begun to query

this fault in our models, and there has been an increasing interest in

strategies for fabricating 3D tissues. Although many methods exist for

fabricating 3D tissues, none boast the benefits in terms of personalization,

and ease of use that bioprinting offers. The life science industry has taken

note of this and an increasing number of companies are turning towards BioBots

for their bioprinting needs. Below is a list of the top 5 ways which

bioprinting is changing the life science industry.

1. Bioprinting miniature organs for drug testing

Perhaps the most common (or most talked about)

application in bioprinting is the opportunity to fabricate miniature organs

that mimic the function of the human body. These miniature organs can be used

to test new compounds on their way to becoming drugs. 3D bioprinted tissues

have a unique ability to elucidate functions of compounds that only arise when

tested in humans, such as liver, kidney and cardio toxicity.

2. Animal-free skin for cosmetics testing

Similar to testing drugs on miniature organs,

cosmetics companies are increasingly turning to bioprinting as a replacement

for animal testing. In recent years, particularly in the European Union, where

all forms of animal testing are banned, cosmetics companies are facing much higher

regulatory hurdles with regards to their use of animal testing models. Being able

to fabricate 100% animal-free skin samples that behave more closely to the way

that human skin does has opened the door to more accurate, more ethically sound

testing models across these industries.

3. Rapid prototyping hydrogel medical devices

Medical device companies are constantly looking

for new fabrication technologies to explore how they can begin to incorporate

new materials into prosthetics and implants.

3D printing offers the huge benefit of cheap prototyping and bioprinting

allows them to blend soft hydrogels with more traditional plastics, metals and

ceramics that are widely used in hip, knee replacements.

4. 3D cell based therapies

This area is still a little green as no

bioprinted cell based therapies have been FDA approved just yet, but there are

a number of companies that are working on

bringing these revolutionary therapies to market. Incorporating

bioprinting into the fabrication process gives an unmatched level of

reproducibility and standardizes the manufacturing process.

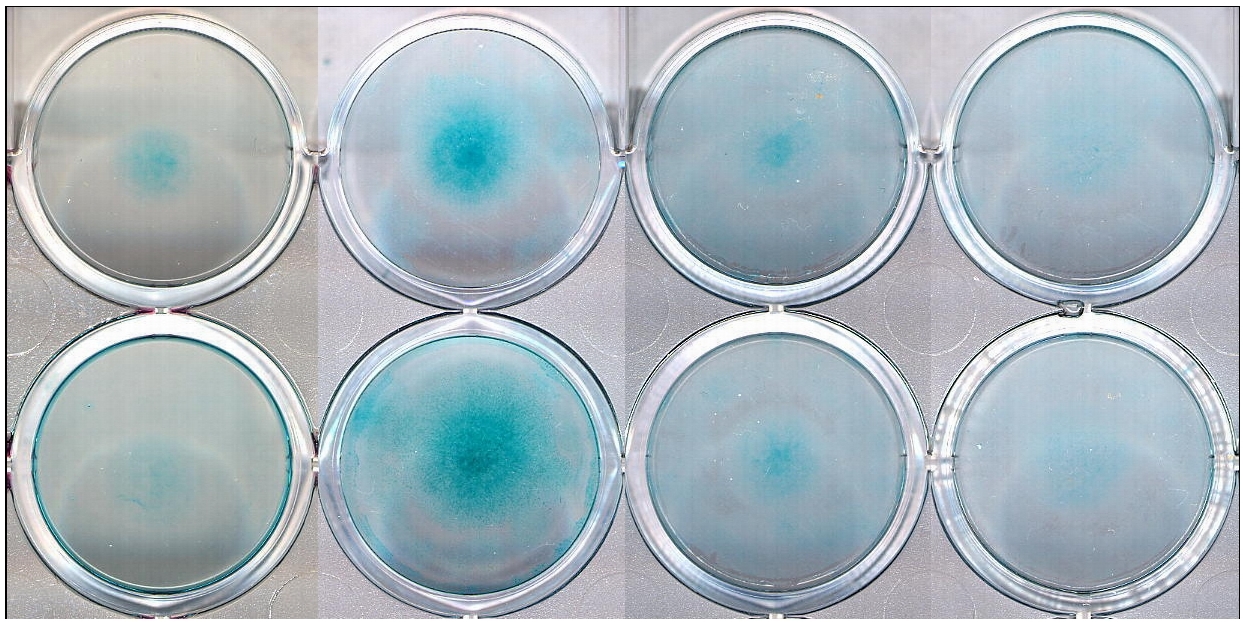

5. More realistic cell culture models

We see a lot of CROs turning to us to fabricate

better tissue culture models. At this

point everyone knows that 2D tissue culture models are not representative of

what’s actually happening in the body, responsible companies are looking for

alternatives, and bioprinting is the best, easiest, fastest and least expensive

way to start fabricating 3D tissues. What do you do with a heterogeneous 3D

tissue culture? Everything that you would normally do with a 2D tissue culture!

www.biobots.io