Custom orthopedic shoes are orthotic devices for rehabilitation and treatment of foot pathological states. The production of orthopedic shoes has always been entrusted to the Orthopaedic Technician for the measures and to the Shoemaker for the realization, as per tradition.

Custom orthopedic shoes are orthotic devices for rehabilitation and treatment of foot pathological states. The production of orthopedic shoes has always been entrusted to the Orthopaedic Technician for the measures and to the Shoemaker for the realization, as per tradition.

The first step is to study the foot, with marks and measurements. In a simple case a wooden or synthetic shape, prefabricated and adapted to the measurements taken, is enough to get the job done. In the most complex cases, due to significant deformities, a plaster mold of the foot is made, so obtained, still raw, is then worked according to the principles of orthopedics and the technique to make the shoes.

Ortopedia Bennica Marasco

Over time, the techniques have been perfected and today we can obtain shoes that are effective and precisely tailored to the needs of the patient, with an exponential innovation in the diagnosis and care of the foot.

The 3D printing builds a new standard

Today, thanks to 3D printing, we can set a new standard in the production of orthopedic and custom shoes.

3D printing in the production of orthopedic and custom shoes.

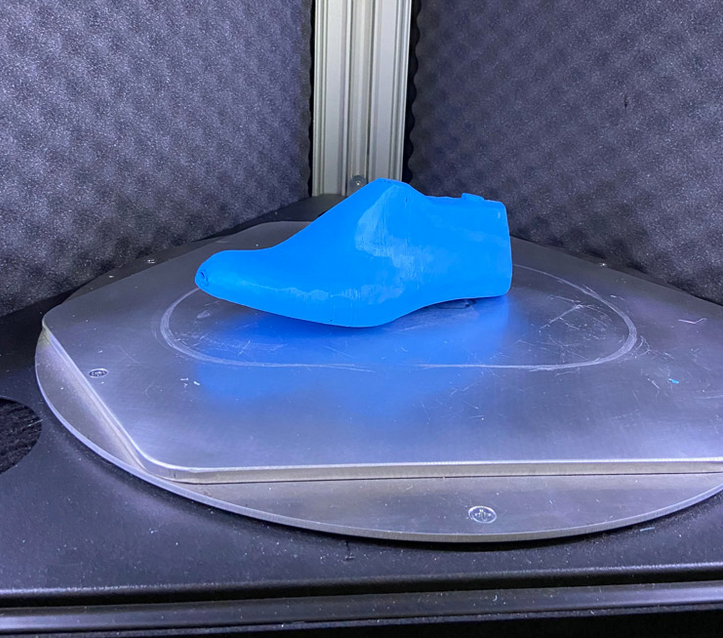

With the 3D scanner, the digital shape of the foot is captured in a few moments and precisely. Specific software for medical devices processes the data in order to design the exact shape, based on the foot of the patient and the model chosen.Once the shape is digitally designed, it is sent to the 3D printer, in this case the Delta WASP 4070 INDUSTRIAL 4.0 and with a good PLA the customized shape will be ready in a few hours

3D printing production of orthopedic and custom shoes with Delta WASP 4070 INDUSTRIAL 4.0

The benefits of “digital customization”

The shape is “digitally customized” and brings great benefits:

Cost-saving not necessary to buy traditional pre-set forms anymore but from time to time ad hoc products are created for each individual customer and that product will have the possibility be modulated later on throughout the patient’s life;

No warehouse not necessary to keep in store a large number of traditional pre-set shapes

Time-saving and cleanliness not necessary to have the chalk cast or change a traditional shape, also eliminating the necessity of hand milling and chalk.

Feet are very important parts of our bodies and taking care of them is essential.

Combining the artisanship of Bennica Marasco Orthopaedics and the technology of 3D Printers Delta WASP has helped improving, reducing and correcting the disorders related to the feet.

wwww.3dwasp.com