Liqtra GmbH is creating a new way to increase the productivity of the FFF printing process without higher speeds or nozzle diameters with the introduction of its latest 3D printer with multi-nozzle technology.

Liqtra GmbH is creating a new way to increase the productivity of the FFF printing process without higher speeds or nozzle diameters with the introduction of its latest 3D printer with multi-nozzle technology.

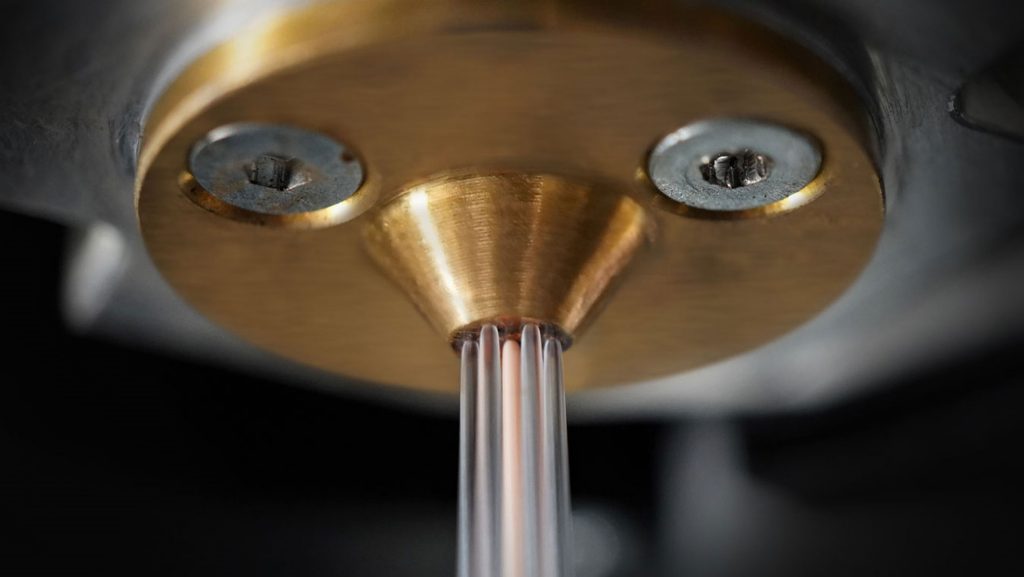

The Liqtra FX-7 Pro's patent-pending multi-nozzle technology achieves a productivity increase of up to 300 per cent, the company says. At the same time, the reproduction of geometric details remains unchanged at a high level and component strengths are even increased by up to 37 per cent. The 3D printer uses up to seven nozzles simultaneously in one print head, each of which can be individually controlled during the printing process. The Liqtra planning software, a slicer specially developed for multi-nozzle applications, makes the process usable for component production.

The software uses artificial intelligence and numerical optimisation to find the optimal part orientation, determine the best process parameters and plan the individual control of each nozzle. The Liqtra multi-nozzle technology uses parallel extrusion from several nozzles throughout the entire printing process. In each process step, the active nozzles and their respective extrusion rates are suitably selected for this purpose.

Liqtra multi-nozzle technology is particularly suitable when medium to large components need to be produced quickly. Fields of application include 3D printing of customised manufacturing aids and patient-specific medical devices.

www.formnext.com