Do you know what's happening on your production line right now? Can you afford not to know? Elisa Smart Factory is a digital 3D Industrial IoT solution that takes your view away from the rearview mirror to the present and the future.

Do you know what's happening on your production line right now? Can you afford not to know? Elisa Smart Factory is a digital 3D Industrial IoT solution that takes your view away from the rearview mirror to the present and the future.

The world has changed so much that data has to be analyzed around the clock. However, many factories are still managed with Excel reports that focus on past events. Moreover, the data generated by production systems is often so isolated that it is difficult to get a comprehensive real-time picture. "So it's no surprise that, according to a survey, over 80% of manufacturing companies are struggling with unplanned production stops," says Kari Terho, general manager at Elisa Smart Factory.

Terho asks management to consider whether the manufacturing industry can still afford a management that looks into the rear-view mirror for data technology. In global competition it is a must to stand out through quality, punctual deliveries and optimized production systems.

Data Analytics is the solution

Elisa Smart Factory is an Industrial IoT solution that uses data analytics to increase productivity and machine availability. Machine Learning is used to analyze historical data and real-time data. Machine processing of the data allows anomalies to be detected and root cause analysis to be supported. Using predictive analytics, errors are even detected and prevented before they occur. In the medium term, the ability to reduce downtime, improve quality and increase productivity and profitability represents an asset and competitive advantage for manufacturing companies that should not be underestimated.

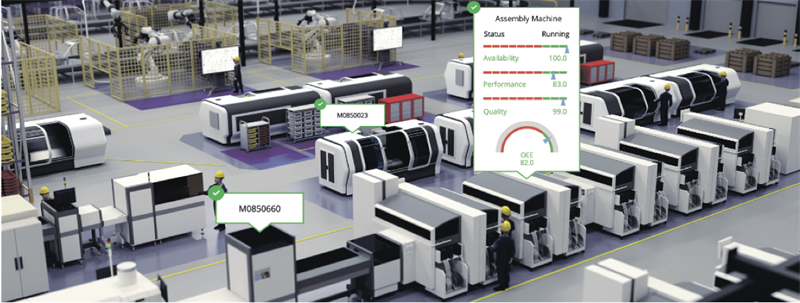

3D view of your factory increases transparency

What does Elisa Smart Factory include? All data sources are connected to each other and the data is collected to create a digital 3D view of the entire factory or individual production lines and to offer monitoring functions differentiated at management and shop floor level. "In this way, the customer receives a visualization of the processes in the company or factory and can receive real-time notifications on any mobile device around the clock. It also helps the manufacturing company get into Industry 4.0 - a system that goes beyond traditional rule-based systems by using AI to learn how to proactively identify defects," says Kari Terho.