Prevent new legislation with epoxysilane-free Henkel adhesives and follow FEICA recommendations

Prevent new legislation with epoxysilane-free Henkel adhesives and follow FEICA recommendations

Consumers expect safe products from the food industry that comply with the latest legislation. FEICA already recommends avoiding the use of epoxysilanes in food contact applications. It is expected that the European Union will set new restrictions on use later this year. These restrictions would require complex test methods, which present processors and packaging manufacturers with far-reaching challenges. Thanks to its many years of experience in the field of food packaging, Henkel has developed a new range of epoxisilane-free laminating adhesives. The company also offers a new test method that combines several sophisticated analytical techniques for detecting epoxysilanes and their degradation products.

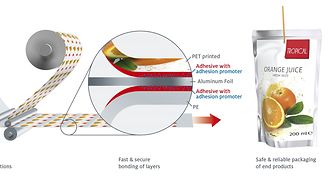

Epoxysilanes such as GLYMO and GLYEO are adhesion promoters used in food packaging - for example, laminated bags - which must withstand sterilization and hot filling. In some cases they are also used for microwaveable packaging. Such adhesion promoters have very advantageous properties, which is why they can be found in a wide range of products. They increase the adhesion between aluminium and polyolefin films and show good bond strength even at elevated temperatures.

Due to the fact that GLYMO is used in a large number of food contact applications, the European Food Safety Authority (EFSA) has taken a closer look at the available toxicological data. In 2017 EFSA concluded that GLYMO must be classified as potentially genotoxic. "Therefore, the European Union is now working on a legislative framework for 2020 to regulate the use of epoxysilanes according to their potential genotoxicity. A timeframe until September 2020 is very likely. This will increase the demand for suitable alternatives," explains Dr. Monika Tönnießen, Head of Food Safety Compliance - Global Food Safety, Product Safety and Regulatory Affairs at Henkel. FEICA, the Association of the European Adhesives and Sealants Industry, already recommends replacing the adhesion promoter as soon as possible.

Changes will affect the entire industry

In the near future, the use of GLYMO as an adhesion promoter will still be permitted, as long as it can be demonstrated that it does not endanger human health. Products containing epoxysilanes must not be used for fatty filling goods, and epoxysilanes must not be detectable in aqueous filling goods. "Critical here is that processors and packaging manufacturers must provide evidence of the absence of GLYMO and structurally similar chemicals like GLYEO themselves. This implies two factors: the right adhesive, or, if epoxysilane-containing adhesives are used, the use of the correct test method. Henkel Corporate Analytics has developed a proprietary and market-leading approach for the determination of GLYMO & GLYEO derivatives. However, the tests will involve additional work and administrative costs for processors in the context of quality control," explains Dr. André Weiss, Manager Instrumental Analytics, Project Management Food Safety at Henkel.

Identifying suitable alternatives

As a leading adhesives manufacturer, Henkel anticipated this development at an early stage and began developing epoxysilane-free adhesives. These systems, which are specially designed for food contact at high temperatures and for use in the medical retort sector, have a modular structure: The Loctite Liofol LA 2798 adhesive base can be combined with a variety of hardeners. This makes them versatile and reduces complexity for processors. Henkel currently offers four hardeners, each with different specifications for a wide range of applications.

Henkel has developed two aromatic hardeners for cooking and pasteurizing dried pet food or hot products. These medium to high performance systems can cure at room temperatures and are designed for high temperature resistance and high heat seal strength. For high performance requirements, Henkel offers an aliphatic hardener for general sterilization, which cures at room temperature and is recommended for 45-minute sterilization processes at 134 °C. This makes it the ideal high-performance adhesive for baby food, for example. A different hardener combination is recommended for the packaging and sterilisation of liquid, particularly aggressive products such as fatty foods and oily fatty contents such as cat food. The modularity of the system makes it possible to reduce complexity while gaining flexibility.

"The adhesive properties and performance of these GLYMO and GLYEO-free adhesive systems have already been confirmed in industrial use by several of our customers. The products are commercially available and offer a very effective way to be on the safe side of the epoxysilane debate at an early stage," explains Dr. Monika Tönnießen.

www.henkel.com