By Marcus Timson

By Marcus Timson

At the recent InkJet Conference in Dusseldorf it was plain to see that inkjet continues to develop in a number of demanding industrial application areas, so it is not surprising that behind the scenes, in R&D labs around the world, state of the art technology is deployed to assist in innovating new technologies for inkjet. Innovation itself requires technology to assist in the development of products and for them to continually improve.

One of the key areas where Inkjet is developing is within functional industrial printing. Arguably, the demands placed upon inkjet for functional printing is the highest of all! This is because functional printing is the most technical of production environments and its use has to contribute to the creation of devices that are lighter, thinner, stronger and more intuitive to use.

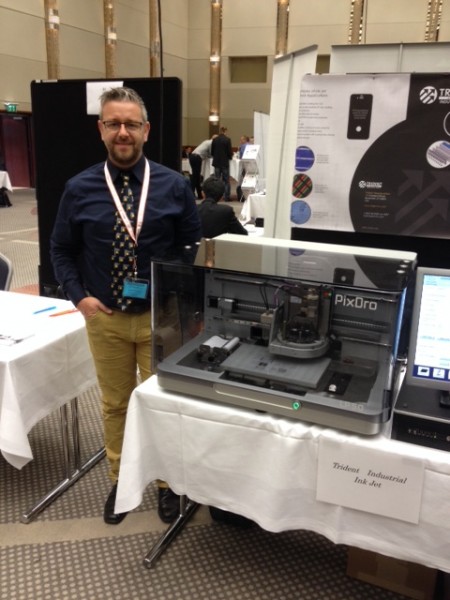

One of the InkJet Conference exhibitors, Roth and Rau and their PiXDRO branded inkjet systems, based out of Eindhoven, have for the past five years developed technology for inkjet machinery production that has a specific focus upon inkjet development.

The PiXDRO System Solution is designed to provide inkjet innovators with the capability of researching and developing functional inkjet technologies.

Dennis Kuppens, Manager Engineering, Roth and Rau, explains, "Originally, our customers were universities, but increasingly businesses are investing in it to produce new products, whether this is new ink for new applications, or indeed for developing a new substrate. Any new product will need thorough testing, plus tremendous analytics to help the innovating company to achieve the best possible performance prior to launching the product into the market."

The PiXDRO LP50 platform is an open, accurate, flexible and easy to use printing system that enables innovators to develop new technologies as a testing technology for substrates and for inks.

Dennis Kuppens continues, "They can be conductive, they can give light and they can be a protective substance. The printed electronics, PCB technologies market is particularly demanding for inkjet as the print is expected to perform well beyond the boundaries of what most people think is possible. Our system is refined for purpose to develop technologies for industrial production and our customers, many of the famous OEMS in the market today, invest with us because the technology assists greatly in their speed to market."

Dennis Kuppens continues, "They can be conductive, they can give light and they can be a protective substance. The printed electronics, PCB technologies market is particularly demanding for inkjet as the print is expected to perform well beyond the boundaries of what most people think is possible. Our system is refined for purpose to develop technologies for industrial production and our customers, many of the famous OEMS in the market today, invest with us because the technology assists greatly in their speed to market."

We as a company are focusing on the printed electronics markets (PCB, Semicon), the energy markets (Batteries, PV) and display markets (OLED, Touch) but the LP50 tool is extremely versatile and is also used for other kinds of applications, like graphical, textile, medical, military and many more.

Dennis explained that the LP50 printer allows to quickly change heads and inks for fast evaluation of different inks. Once the process has been developed into a stable process, pilot production can be developed further on the IP410 which is a custom made machine module. Once the pilot is up and running one could move to a full production solution from Roth&Rau.

The PiXDRO system can use Trident, Xaar, Konica Minolta and Dimatix heads. The pixdro systems are kept up to date with new printhead types that become available on the market regularly. At the Inkjet Conference PiXDRO were co-exhibiting with Steve Liker from Trident, who explained that for industrial production, the Trident head is particularly effective as it is made out of stainless steel meaning it was very robust, with less clogging enabling the jetting of acids and other caustic fluids with the head itself being capable of lasting up to a year which makes it a good investment.

The PiXDRO LP50 is equipped with cameras that look underneath the print head so you can see the ink droplets and accurately measure the speed, accuracy and drop formation so you can amend accordingly to production requirements.

The system is also automated to run to an optimal model and it provides data so you can set production to run at the best possible amplitude, pressure or wave form. For inkjet this is really important because you still are jetting a fluid and this is in itself a complex process.

PiXDRO technology clearly contributes to the continual improvement of inkjet. When you get an ink and a print head you need to optimise and as we see an increase in demand for functional inkjet printed materials, the systems that aid innovation are growing in their sales and use within R&D across the world of inkjet innovation.

Dennis Kuppens concludes, "In the future we see that mobile phone screens will be printed using inkjet and this integration is exciting because it makes the device lighter and thinner but the challenges are considerable as the tolerance of imperfection is virtually zero. The thinner the phone gets more innovation is required to print elements of the functional device that may not be printed currently."

The future of InkJet in industrial applications is very positive and as the world continues to demand technology that gets faster, lighter, stronger and more flexible, inkjet will continue innovate and improve to meet this demand.

So a marginal gain in production can mean a huge leap forward in capability, particularly if the improvements are committed and continual. At InPrint 2015, we look forward to seeing how this plays out on the show floor.

www.industrialprintshow.com