Predictable print results combined with increased speeds to be demonstrated on booth 11C20

Predictable print results combined with increased speeds to be demonstrated on booth 11C20

MPS will introduce its new E-Sleeve technology at Labelexpo Europe 2019 (booth 11C20) September 24-27 in Brussels, with key features presented in live demonstrations on the EF SYMJET hybrid press.

Designed as a superior alternative to traditional sleeves that use compressible material, the new MPS E-Sleeve enables printers to generate predictable results at increased speeds, with guaranteed quality tolerances and more reliable production cost calculations.

“Flexographic printing sleeves play a critical role in the overall flexo printing process, as they have a major influence on print efficiency and quality,” said Bert van den Brink, MPS Co-Founder. “We at MPS saw the need to change from sleeves that use an aero-mounting principle with a compressible inner core, to a design with precise concentricity across the entire plate for optimum print results. It’s a game changer for the printing industry!”

Key features of the MPS E-Sleeve include optimum pressure settings to avoid unnecessary bouncing, precise concentric runout properties, constant parallelism for ideal register across the entire print length and increased dimensional accuracy for optimum register between all colours and die stations.

With a reduced weight, MPS E-Sleeves provide easier and faster job changeovers and lower lifetime tooling costs through improved durability.

Also at Labelexpo Europe will be the launch of a wider version (17” / 430 mm) hybrid MPS EF SYMJET press integrated with the new Domino N617i unit. The press will be equipped with five flexo stations, digital cold foil, a Kurz cold foil unit for single images and optical effects, lamination and die-cutting.

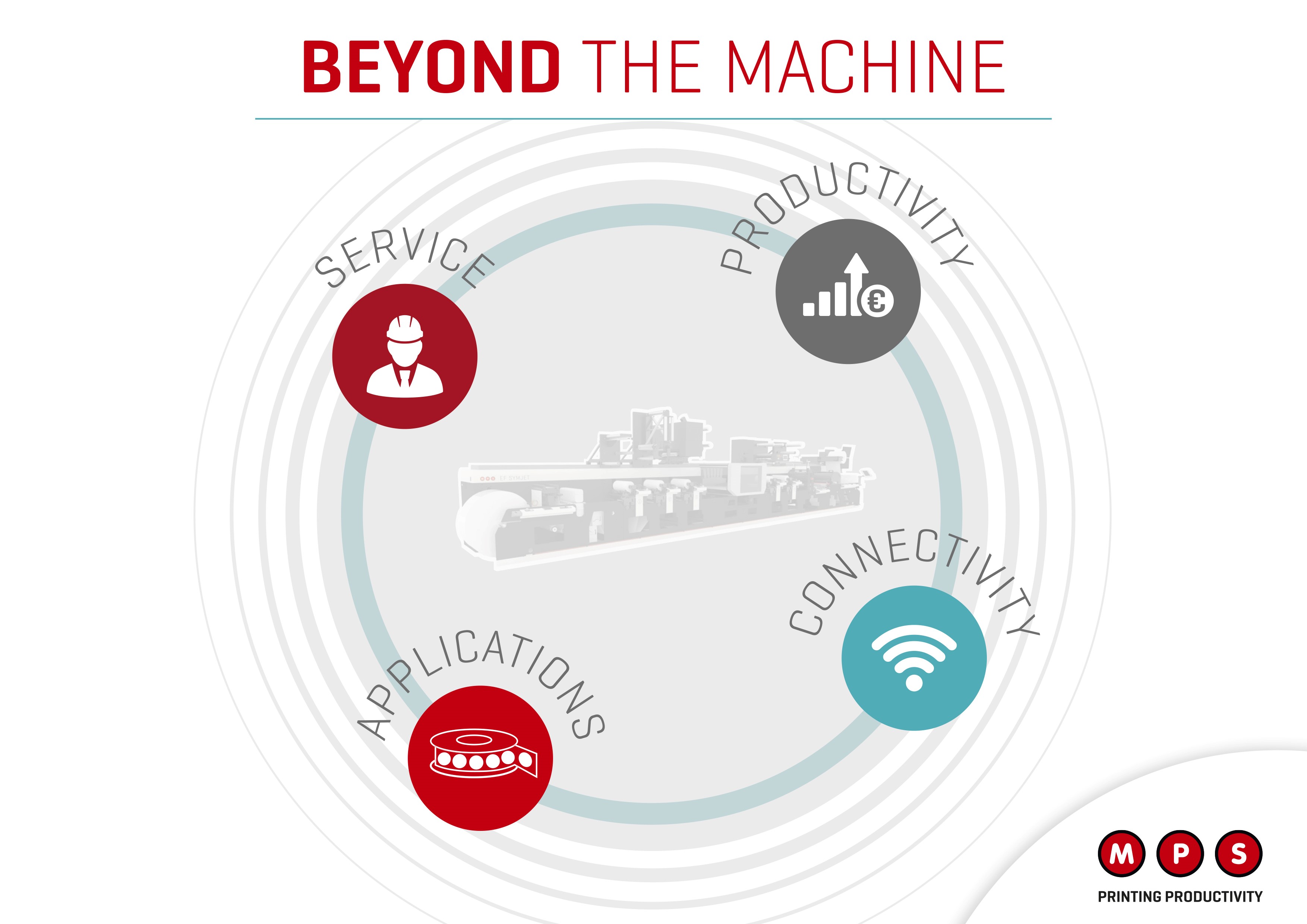

The main theme on the MPS booth 11C20 at Labelexpo is ‘Beyond the Machine’ where visitors will learn more about MPS and their strengths in four key processes: Connectivity, Applications, Productivity and Service.