Visitors to the BOBST stand #D6 at Labelexpo Asia in Shanghai, China, 3 – 6 December 2019, can expect to hear the latest from the frontiers of labels and packaging printing and converting. Dazzling video displays will illustrate exclusive technologies that will provide exciting new opportunities for converters, driven by the digital revolution.

Visitors to the BOBST stand #D6 at Labelexpo Asia in Shanghai, China, 3 – 6 December 2019, can expect to hear the latest from the frontiers of labels and packaging printing and converting. Dazzling video displays will illustrate exclusive technologies that will provide exciting new opportunities for converters, driven by the digital revolution.

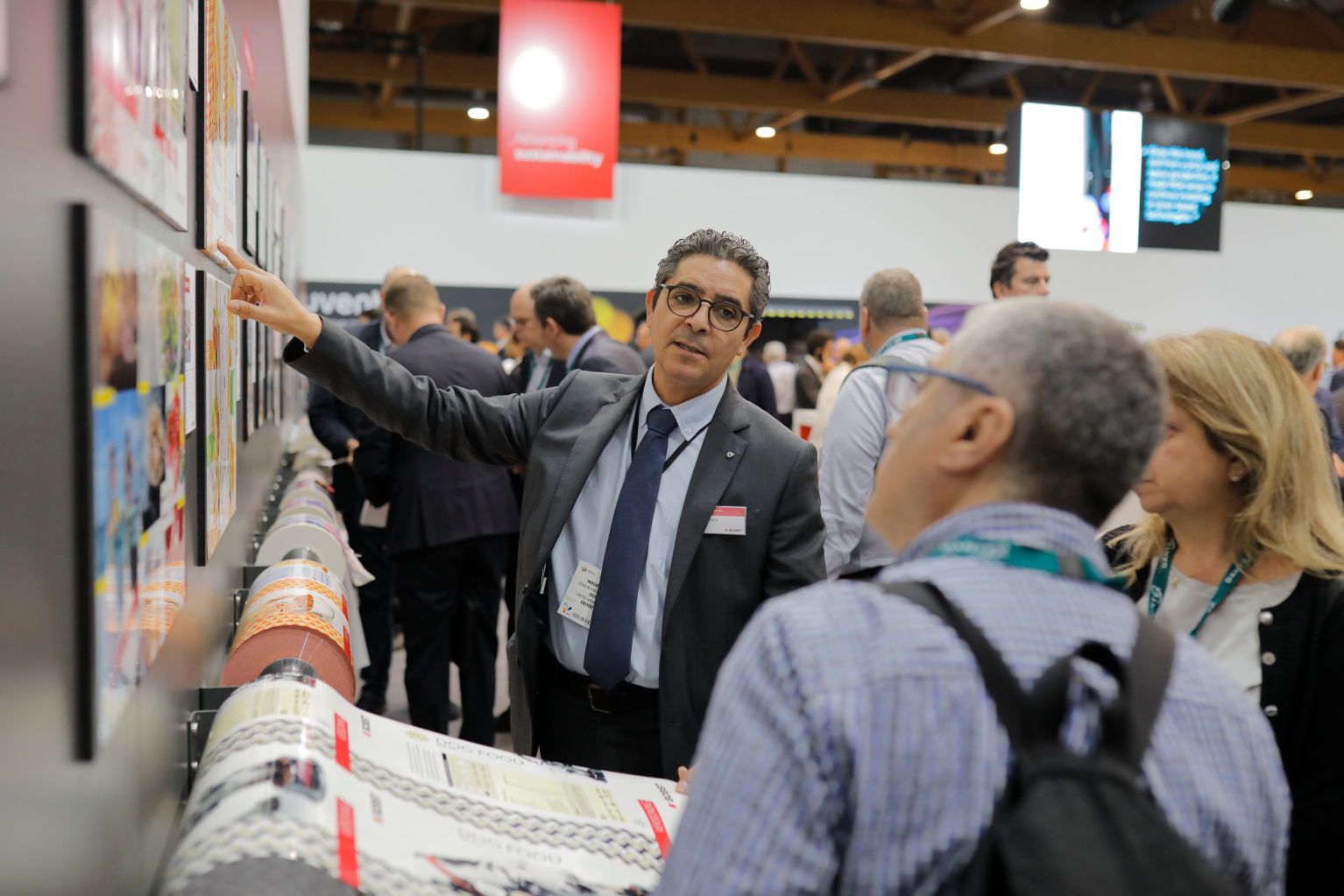

“Participation to Labelexpo Asia next December will be the crowning finale to an extraordinary year for BOBST in terms of the unique innovations we have introduced to our range of digital, hybrid and DigiFlexo presses and printing and inline converting processes,” says Matteo Cardinotti, Head of the Narrow & mid-web multi-process & converting Product Line at BOBST. “We look forward to illustrating them in detail to the visitors of our stand at Labelexpo Asia”.

These include:

- The brand new MASTER DM5 hybrid press, the most digitally automated machine in the label market. Digital and analogue printing and converting are perfectly integrated to achieve the highest uptime in the industry. Exceptional print quality at up to 100 m/min guarantees the fastest time-to-market for most label applications.

- DigiColor: the first ever inline closed-loop system in the flexo industry that enables digital color adjustments to the target Delta E during printing, at any speed, on any substrate, with any operator, anywhere in the world.

- Ink-on-Demand (IoD) the first print unit without conventional inking reservoirs that uses only 30 grams of ink for color matching and printing. Featuring fully automated on-board washing of the print unit in less than one minute, it is the most sustainable print unit on the market

Further highlights at the show will be the technologies stemming from BOBST collaborations with leading industry suppliers, such as a range of new technologies for UV food safety, or innovative workflows developed within the REVO Technology Team, such as Packaging Connected. The latter development is a fully digitized and connected workflow enabling the traceability of every item of packaging, from the original file, to the press, to job validation and storage of the digital data generated from the final printed job. These advanced technologies are features of BOBST DigiFlexo lines for label and packaging production such as the MASTER M5 and the MASTER M6.

The Solution and Services dedicated areas will complete the overview of BOBST wide capabilities and commitment to be a unique solution partner to the label and packaging industry through the functionality and quality of a variety of different application samples. BOBST services portfolio includes a range of apps and technical support that bring full connectivity to converters’ equipment and processes.