Russian printer places order via video call during COVID-19 crisis

Russian printer places order via video call during COVID-19 crisis

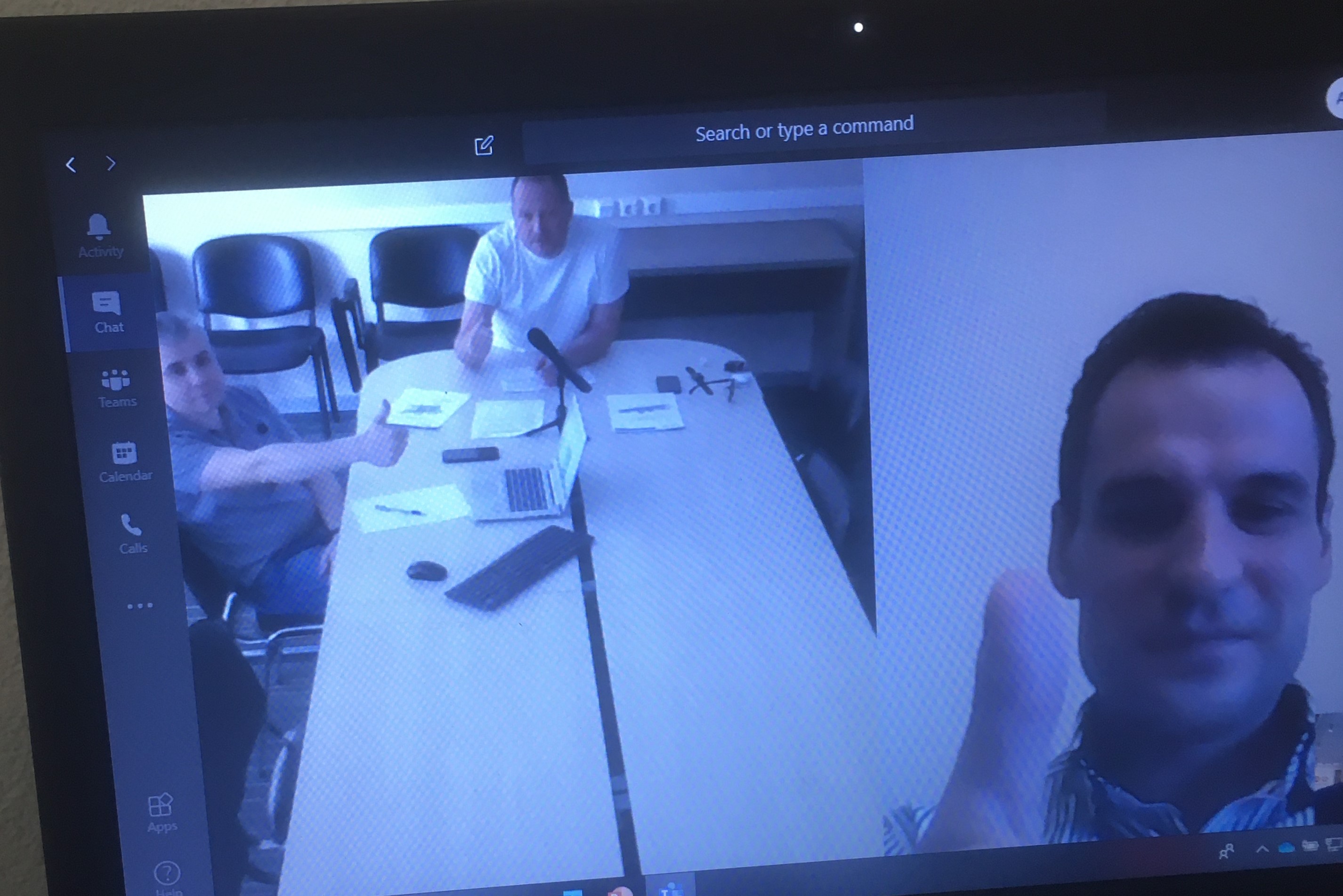

Russian printer Impress located in Barnaul, Siberia confirmed an order for their second, fully automated MPS EFA+ 430 presses via Microsoft Teams group video call.

Ordered was an 8-colour 430 mm wide, fully automated MPS EFA+ flexo press to further increase label production capacity and expand options in being a leading smart label provider. The MPS “Beyond the Machine-approach” with Talk to me connectivity platform was the driving force in this second press purchase.

“We’re highly focused on information technology and Industry 4.0 as automation and process improvement are a top priority at Impress,” said Pavel Startcev, Impress owner. “Based on experience with our first MPS flexo press, the machine has proven very reliable performance and produces outstanding final product quality.”

“We decided again for MPS, as its innovation in connectivity is truly impressive. Together with increasing production, we’re ready to make a huge step in connectivity and process automation.”

More transparent production with MPS “Beyond the Machine”

MPS Systems helps make the transformation to a smart label industry and gives printers more insight into their processes and equipment productivity by connecting their printing machines and workflow with Management Information Systems (MIS) for real-time data exchange and control.

“We’re interested in obtaining the maximum amount of data from our MPS press, to analyze parameters of our printing jobs and increase productivity,” said Konstantin Kokin, Managing Director of Impress. “Buying the press with built-in Talk to Me connectivity, we understand that in addition to helping us gain direct insight into the cost price per label, it also helps make our entire production more transparent in process automation. We’ll know the exact values of waste consumption, machine capacity, setup time, job management, quality and more useful data without relying on inputs from print operators.

“We believe MPS is the right choice for the future of Impress. We look forward to the press installation and further exploring the power of MPS.”