According to the new mission statement "perfecting your performance" of the group, BST eltromat International presents at the K 2019 (16th - 23rd October in Düsseldorf / Germany) in hall 4 (booth C34) the latest possibilities for an efficient quality assurance in different process steps of the web processing plastics industry. In keeping with the ubiquitous topic of circular economy, the company will be placing a special focus at this year's K on supporting a functioning circular economy. Further central topics are the reduction of set-up times, the exclusion of sources of error even before the machines start up and the further increase in operating convenience in quality assurance.

According to the new mission statement "perfecting your performance" of the group, BST eltromat International presents at the K 2019 (16th - 23rd October in Düsseldorf / Germany) in hall 4 (booth C34) the latest possibilities for an efficient quality assurance in different process steps of the web processing plastics industry. In keeping with the ubiquitous topic of circular economy, the company will be placing a special focus at this year's K on supporting a functioning circular economy. Further central topics are the reduction of set-up times, the exclusion of sources of error even before the machines start up and the further increase in operating convenience in quality assurance.

"In line with our claim to support our customers in achieving the best possible production, we will be demonstrating in Düsseldorf how companies in the web processing plastics industry all over the world can harmonise their economic and ecological goals with solutions from BST eltromat. By minimizing their use of resources and waste with our technology for web run control, register control, web monitoring, 100% inspection and color measurement, for example, they improve the life cycle assessments of their companies and their products. At the same time, they ensure a constant quality level in their production with short set-up processes. In addition, we are demonstrating how the integration and automation of various process steps can further improve quality assurance results and thus further increase production efficiency," says BST eltromat marketing manager Anne-Laureen Lauven, outlining the topics at the company's booth. BST eltromat will also be taking part in the VDMA Circular Economy Forum on the open-air grounds in front of Hall 16 at K 2019. The association will be providing information on the subject of recycling management with data, facts and practical examples.

The comprehensive portfolio of innovative sensor technology from BST eltromat forms a focal point of the exhibition at the company's stand. "With our ultrasonic sensors, optical sensors, digital sensors and wide-range sensors, we cover the diverse quality assurance requirements of the plastics industry from a single source. In the increasingly digitized production processes of our customers, our sensor technology is becoming even more important as a link between machine hardware and digital technology - after all, it provides the information needed to optimize production processes," explains Kai Prahl, Area Manager in Sales at BST eltromat in Germany.

Integration as the key to higher efficiency

In this context, under the keyword Converting 4.0, the interaction of a digital line and contrast sensor CLS PRO 600 from BST eltromat with a slitter rewinder and the integrative platform the@vanced from KAMPF Schneid- und Wickeltechnik can be seen in Düsseldorf. The simulation shows how the sensors and the motor-driven knife axis of the slitter rewinder are set up automatically with the integrated technology. In this application, the knives are no longer aligned with the sensor, but the motifs on the material webs are aligned with the knife axis. The sensor in turn automatically moves to the specified lines. The production data for slitting can flow directly from ERP systems into the control systems of the systems. Automatic cutting pattern alignment simplifies and significantly shortens setup times in the cutting process, eliminates sources of error and avoids rejects - which meets the demands for greater sustainability in the packaging industry.

Innovative control unit with fieldbus capability

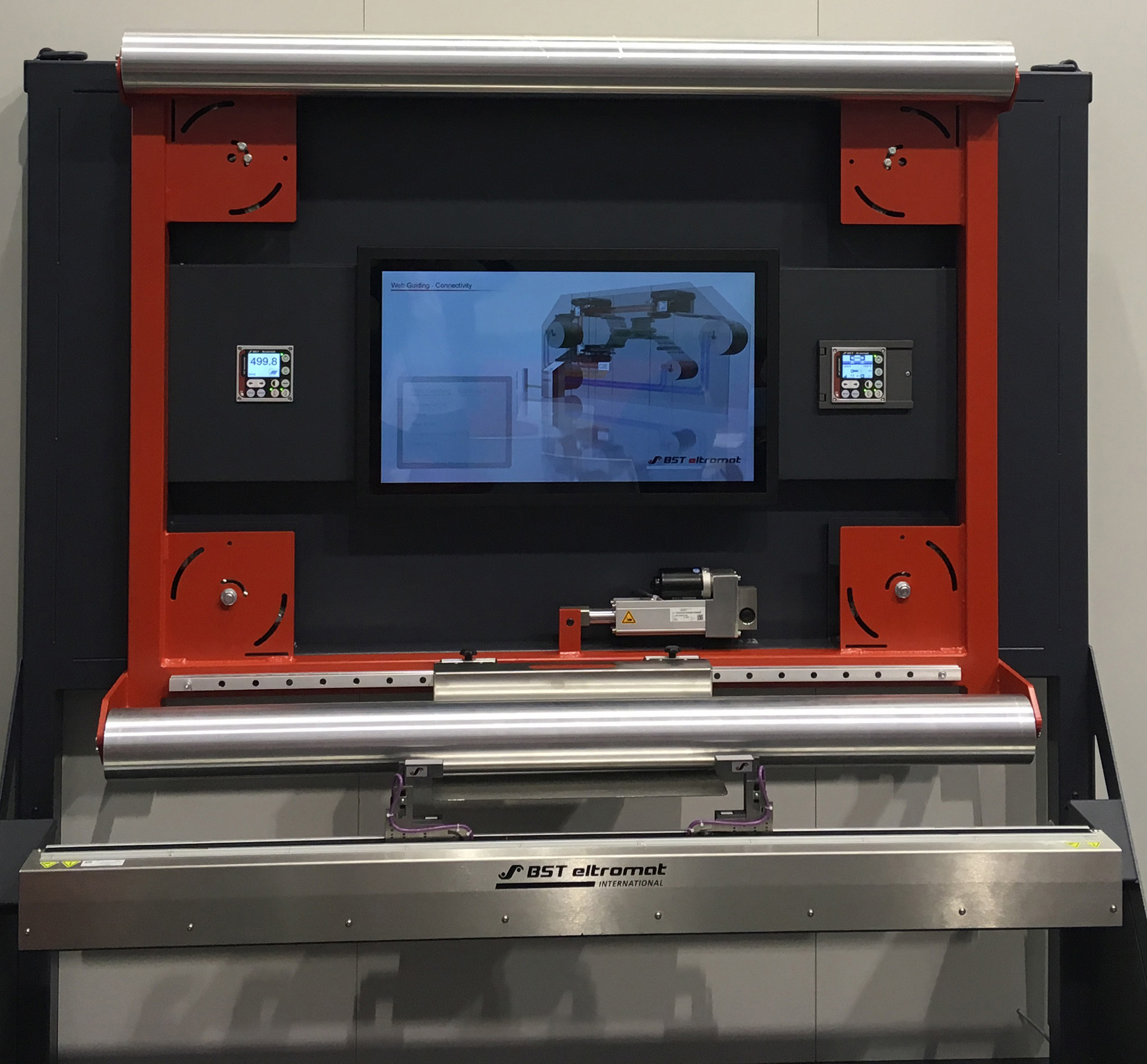

The new controllers of the ekr CON 600 family fit into the same picture. BST eltromat is presenting this in Düsseldorf for its web guiding controls. With the ekr CON 600 and the ekr CON 600 net, this new family consists of two innovative controllers with an extended range of functions. The ekr CON 600 net is additionally equipped with a fieldbus. Both controllers offer the same operating philosophy as the other controllers from BST eltromat. This means that setup and operation are both intuitive and simple for the machine operator via the touch control panel. Ingo Ellerbrock, Head of Product Management at BST eltromat: "The new control device gives our customers the opportunity to easily expand their field bus system with a web guiding system and to use the information provided by the web guiding system to optimize their processes. They can set up their web guiding system faster, operate it more efficiently and increase their process reliability". This also reduces or avoids waste in production. Customers who initially opt for an ekr CON 600 can switch to an ekr CON 600 net at any time without having to make any changes in their processes.

Produce perfect results quickly and easily

Also in the field of quality assurance with the iPQ-Center, BST eltromat is focusing on simplified set-up processes at the K. Among other things, the company will present COLOR DATAPreparation and SMART DATAPreparation, two innovative options with which the inline spectral color measurement iPQ-Spectral can be set up automatically for applications such as printing flexible packaging. With COLOR DATAPreparation the data for inline spectral color measurement can already be prepared in prepress, production planning or quality management. Employees enter the measurement positions, L*a*b*, density and tonal values manually or import them in the form of CxF files. COLOR DATAPreparation then generates virtual print control strips and transfers them to iPQ-Spectral before printing begins. iPQ-Spectral is not only used by packaging printers, but also by film manufacturers, for example, to control the colours of their products.

SMART DATAPreparation networks the iPQ Center with ERP systems, for example. Job data such as job names and numbers, recipes, reference values and measuring positions can flow directly from these systems to the iPQ Center. With iPQ-Check for 100% print image inspection, iPQ-View for digital web inspection and iPQ-Spectral, the iPQ-Center consists of three modules that the iPQ workflow integrates into a high-end system for the central control of numerous quality assurance functions. The iPQ Center now provides machine operators with enlarged error views in the error logs, making their work even clearer. "COLOR DATAPreparation and SMART DATAPreparation are two examples of how we help our customers produce perfect results quickly and easily with less waste under the motto perfecting your performance," says Volker Reinholdt, Product Manager Print Inspection at BST eltromat.

Responding to individual customer requirements

With its standard solutions for web guiding control, register control, web monitoring and 100% inspection, BST eltromat covers a large part of the requirements of the web processing plastics industry. Depending on how the BST eltromat systems are configured and integrated with solutions from other manufacturers, they open up additional possibilities for joint customers. "This is exactly what we want to emphasize in Düsseldorf with our cooperation with KAMPF Schneid- und Wickeltechnik. The integration shown here is based exclusively on standard tools from BST eltromat. In addition, we have contributed our know-how to this integration. If customers approach us with individual requirements, we check with them whether it is necessary to develop tailor-made solutions for them that best support their processes. In other words: We can leave it to our customers to decide whether they want our solutions to remain standard or whether we adapt them to their individual requirements. It is crucial that they achieve their economic and ecological goals with our technology," says Ellerbrock.

www.bst.group