Flexible film production innovations deliver enhanced quality, productivity and energy efficiency

Flexible film production innovations deliver enhanced quality, productivity and energy efficiency

Baldwin Technology Company Inc., a world-leading provider of process enhancement technologies for flexible film, sheet and print production, is pleased to announce its participation at K 2019, Dusseldorf, October 16-23. At booth C53, hall 4, Baldwin Technology will showcase ground-breaking cleaning, surface treatment, coating and drying innovations tailored to optimize process profitability.

“We are proud and excited to show our state-of-the-art innovations ideal for flexible film extrusion, lamination and printing systems at K 2019,” said Peter Hultberg, CCO, Baldwin Technology. “For example, we will show how you can gain additional hours of extra production time a year thanks to our automatic cleaning system.”

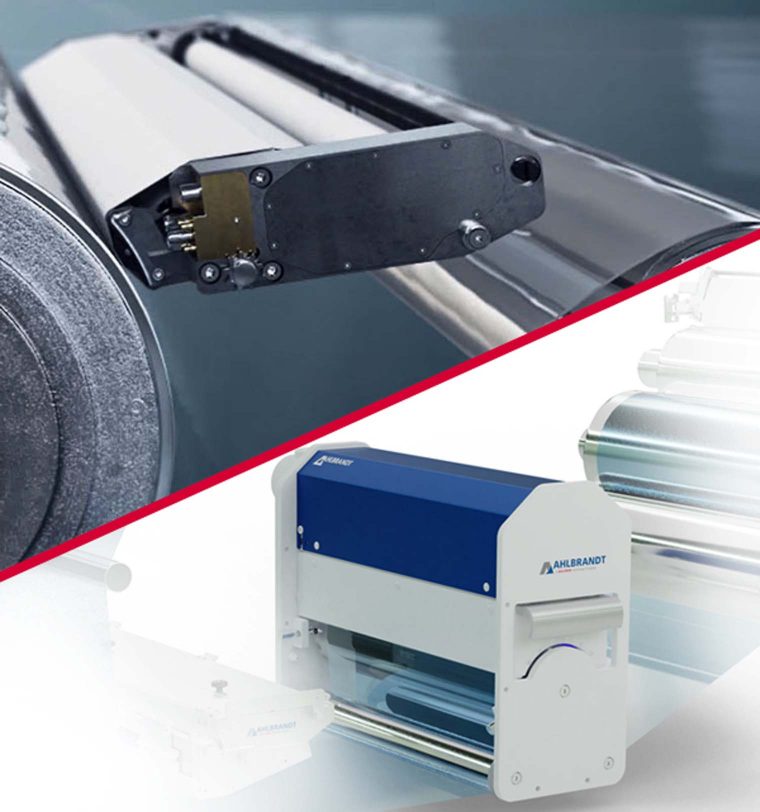

Baldwin’s proven FilmCylinderCleaning system offers automated and highly efficient cast and chill cylinder cleaning performed during operation, enabling maximal uptime while enhancing the film quality. Valuable production time and material costs are saved. Manual cleaning of chill rolls can take in averages 30-60 minutes, often with the extrusion line being stopped. Automated cleaning with Baldwin’s FilmCylinderCleaning only takes 2 to 3 minutes.

Also new to the plastic film industry and presented at K 2019, is a new generation of Ahlbrandt Corona technologies. The highly energy efficient Ahlbrandt Corona surface treatment feature top-of the line-performing electrodes, ensuring enhanced ink and glue adhesion leading to flawless printing and laminating results. Thanks to its innovative solutions for fast and easy service, electrodes can be changed in just a few seconds, maximizing the production uptime.

The even and precise Ahlbrandt Rotor Spray coating secures a film quality with long term anti-fog properties and release for demolding thermoformed parts. Utilizing a non-contact application technology, it saves both chemistry and energy consumption and unlike other processes, there is no harm to any recycling of the finished film.

The high-efficiency Ahlbrandt Hot Air Dryer solutions are specially designed for drying of plastic films at low temperature and at top production speeds with optimum edge-to-edge evenness.

Baldwin’s innovations deliver complete process enhancement for flexible film and sheet extrusion production as well as excellent print results. By empowering the quality of film characteristics for a flawless product and improving the overall quality, process productivity and energy efficiency, the production will be more profitable and sustainable.