Milliken & Company, a globally recognized leader in polymer additives and colorants, offers many ways to improve your resin formulations, compounds, end products and sustainability. As an exhibitor in Booth B2-2105 at Fakuma 2021, Milliken will be showcasing its portfolio, and offering access to the vast technical knowledge of its various experts.

Milliken & Company, a globally recognized leader in polymer additives and colorants, offers many ways to improve your resin formulations, compounds, end products and sustainability. As an exhibitor in Booth B2-2105 at Fakuma 2021, Milliken will be showcasing its portfolio, and offering access to the vast technical knowledge of its various experts.

At the show — taking place Oct. 12-16 in Friedrichshafen, Germany — learn more from Milliken about the following products:

Millad® NX® 8000 ECO clarifier for polypropylene (PP);

KeyPlast® and KeyPlast RESIST™ colorants for plastics;

Hyperform® HPN® high-performance additives for PP, polypropylene homopolymers and impact copolymers (ICP); and

DeltaMax® performance modifiers for PP used by converters processing impact copolymers or recycled polypropylene (rPP) resins.

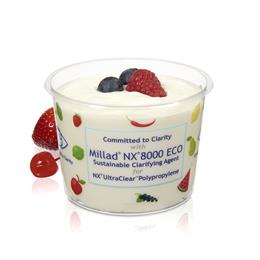

Clarity & sustainability

Milliken’s Millad NX 8000 ECO clarifier is the latest addition to its market-leading Millad NX 8000 product range, which is used to produce the durable, fully transparent, highly recyclable material known as NX UltraClear™ PP. Millad NX 8000 ECO offers the added benefit of even faster production rates, contributing to average energy savings of 10% for the production of clarified polypropylene parts — a fact certified by UL (Underwriters Laboratories).

The U.S.-based Association of Plastic Recyclers also recognizes the ECO grade for its compatibility with plastic packaging recycling. Additionally, the technology is fully compatible with PP recycling processes in Europe and poses no recyclability issues, according to RecyClass, a cross-industry initiative that works to advance plastic packaging recyclability on the continent.

In addition to improving overall sustainability, it also delivers tunable clarity to meet specific market needs while minimizing the risk of defects such as white specks, streaks and voids. Millad NX 8000 ECO also addresses concerns related to migration, especially in food-contact applications by reducing specific migration limits, or SMLs, without adding any new ingredients to the formulation.

Colorful results

Milliken’s KeyPlast colorants for plastics are versatile products that can be used by liquid and solid masterbatch producers, resin producers and compounders, and are suitable for use with a wide range of polymer and resins systems. The FDA-compliant KeyPlast colorant range for polyethylene terephthalate (PET) can be used to create distinctive shades in both transparent and opaque applications. Ideal for food-contact applications, this specially developed range is well suited for beverage bottles, pharmacopeia containers, and for products that require differentiated design.

Additionally, Milliken has fine-tuned its KeyPlast RESIST colorants to perform well in extreme temperatures in various engineering polymers, including polyamides, polysulfones, PEEK and other high-heat polymers and alloys. Such materials traditionally have been more difficult to color, and often are used in demanding applications such as power tools, automotive parts, gears and appliances.

Vital processing aids

Several grades in Milliken’s energy-saving Hyperform HPN range of performance additives for PP will also be on display at Fakuma. These additives are easy to use and reliable while also improving the performance of recycled polypropylene (rPP). They enable thermoformers and injection molders to produce stronger, lighter parts. In addition to increasing stiffness significantly when compared to conventionally nucleated resin, they also aid processing productivity and offer balanced, tuneable properties.

UL Environment & Sustainability, a unit of the global UL group, confirmed that it has reviewed and certified that grades of Milliken Hyperform HPN range enabled an average of 5-8 percent energy savings for firms that injection mold thin-wall container lids or similar PP products, earning the products UL’s Environmental Claim Validation label — a key marketing benefit.

Come discuss which HPN grade is ideal for your application.

Hyperform HPN 909ei, designed for use by thermoformers in PP homopolymers and mini-random copolymers, is typically used to make drink cups and lids, food packaging and thermoformed trays. It offers improved aesthetics and has been developed using a clean chemistry. For such food-contact applications, it has one SML less than the previous-generation product, which is critical as regards European Union regulations.

Hyperform HPN 715 is designed for use by injection molders in polypropylene homopolymers and impact copolymers to yield the highest stiffness possible in the resin while retaining good impact resistance. Hyperform HPN 715-modified PP allows downgauging and reduces filler requirements, thereby improving design freedom, reducing weight, and cutting material costs. It enhances the physical and thermal properties of PP, hence offering new opportunities for PP to replace more-expensive engineering resins in demanding applications, from microwaveable containers and industrial packaging to under-hood vehicle components and household appliance parts.

Hyperform HPN 500ei, meanwhile, provides high stiffness and improved optics to parts thermoformed from the PP homopolymers that contain it. Resulting products such as drink cups and sheet not only have a better heat deflection temperature, but also a significantly cleaner, newer appearance that can rival that of PET.

Enhancing PP’s properties

Milliken’s DeltaMax Performance Modifiers for polypropylene help contribute to a circular economy by enhancing the impact strength and melt-flow properties of rPP resins, blends and PP impact copolymers. DeltaMax can raise melt flow by as much as five times while maintaining impact and stiffness properties. This allows converters to increase operating efficiencies and create more innovative part designs with easier flow through molds. DeltaMax technology also is highly effective in modifying post-consumer and post-industrial recycled resins. It elevates impact strength and melt flow to the same levels as – or better than – those of virgin resin. This enables compounders and converters to incorporate up to 100% recycled PP without sacrificing performance or processing.

Learn about all of these products and more from Milliken experts at Fakuma.

www.milliken.com