An Interview with the Team Responsible for the Development of the 5mmR "Active Bending" Plastic OLED Display that Turned Heads at CES 2015

An Interview with the Team Responsible for the Development of the 5mmR "Active Bending" Plastic OLED Display that Turned Heads at CES 2015

At CES 2015 held in January in Las Vegas, the Active Bending Plastic OLED (P-OLED) for mobile devices was demonstrated at the LG Display booth and immediately received an enthusiastic response from the crowd. This newly-showcased display received so much attention because it truly demonstrated LG Display's technical expertise, which allows both ends of the display to be bent at a more sheer curvature.. There was an opportunity to interview the 7-engineer team who made this impressive technological breakthrough possible at LG Display.

Let's put the possibilities of plastic to the test

Due to the flexible characteristics of plastic OLED displays, everyone who sees one tends to subconsciously bend and twist the display. Tae-Jun Ahn, Chief Research Engineer of the Active-Bending P-OLED Development Project Team, says that the material known as plastic has 'inherent potential'. The team said that since this is a field with limitless applications, the first step was to curve both edges of the display.

However, there are still issues with the development of the Active Bending display. A display bent at a limited curvature has the tendency to bend back to its original form and development must be done to suppress this tendency. Also, there is a need for developing a solid adhesion method for flexible displays to give them maximum flexibility while preventing components such as the OLED and TFT materials, as well as the inorganic materials beneath the plastic substrate from breaking when being bent or twisted.

Technology that enables a display to roll up to the thickness of a ballpoint pen

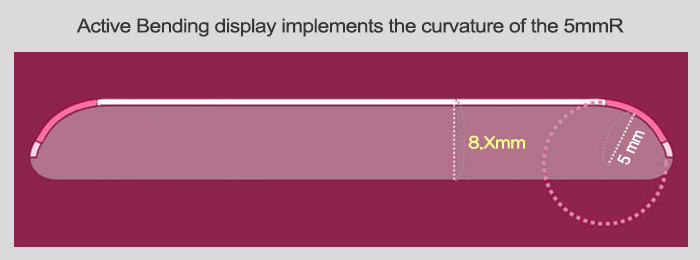

While the ability to curve the edges of the display created with Active Bending technology is impressive, While impressive is the ability to curve the edges of the display, which was created with Active Bending technology, there is a buzz around the development of more advanced displays that can bend at a curvature of 5mmR (bend into a circle with an approximate 5mm radius). The process for allowing both sides to bend as opposed to just one side is more difficult. But the most important issue here is developing the structure of an optimal panel that can bend at the highest curvature without causing damage to or wearing out the display functions.

Tae-Jun Ahn, Chief Research Engineer, explains further

Tae-Jun Ahn, Chief Research Engineer, explains further

"Most displays such as LCD and PDP are made with glass. But since this product is made from plastic, the panel can be bent freely from the edges or the middle. Of course, even though the substrate is made of plastic, the panel cannot help but break when bent beyond a certain point due to the OLED and TFT materials and the inorganic materials in the panel. The prototype demonstrated at CES 2015 can bend at a curvature beyond a radius of 5mmR, but when bent beyond that, the product cannot be used as a display."

"What we have developed is a technology that protects the OLED and TFT materials in the display from being damaged. This technology is called 'neutral plane configuration'. The most important point about this technology is optimization of the panel structure and that is what we have been researching here."

How do you bend a display that is almost always straightened?

"Since this Active Bending display, which allows its edges to be bent, did not previously exist in the market, it was difficult to even find companies to collaborate with for development. Display manufacturers make 'flat' displays and there are almost no companies that can make 3D form products. There were also other problems in the development process."

"While plastic panels adhere together well from the beginning, they tend to come apart on curved surfaces over time. This is something you do not have to worry about when making a flat display. Development of technology to strengthen adhesion and resolve this issue was necessary."

The most significant force in resolving this issue was Chief Researcher from the PO Mechanics Design Team, Junjae Lee. He resolved the issue by developing an adhesive to go between the panel and the cover glass to keep the two from separating after the plastic panel is adhered through the process of "Direct Bonding."

Renovation of equipment and processes

Renovation of equipment and processes

But what is the difference in the processes for making a curved display like that in the G Flex and for making this Active Bending display?

"First of all, the flexible display in the G Flex can bend at a much larger curvature than the Active Bending display. As the G Flex display is slightly curved, there are no issues in adhering the panels. However, since the Active Bending display is bent at such a sheer curvature, even the manufacturing equipment itself had to be developed from scratch."

Tae-Jun Ahn expanded on what Junjae Lee had to say explaining, "Plastic has a diverse set of characteristics and one of those characteristics is resilience. This means that it returns to its original state even after being bent. If we say that the strength of resilience on a 700mmR curvature display is approximately 500g, then the strength of resilience of a 5mmR curvature display is between 3kg and 9kg. This is the standard that must be met.

Chief Researcher Saejun Cho says that counterbalancing the strength of resilience through adhesion is the most difficult challenge. It's like this, when you use a smartphone, you don't only use it inside but also out in hot and rainy weather. The product must be made so that the adhesive on the curved display does not detach in 80% humidity and at 60℃ or even 80℃ degrees. This was not an easy task, but everyone involved in the development process showed great patience and completed the development of the Active Bending display that began as merely technological potential."

ww-lg.com