With the commercial launch in October of Screen's JetConverter L350 digital label finishing line, printing companies that operate the Screen Truepress Jet L350UV inkjet label press will have an easy and cost-effective way to create full-color finished labels on demand.

With the commercial launch in October of Screen's JetConverter L350 digital label finishing line, printing companies that operate the Screen Truepress Jet L350UV inkjet label press will have an easy and cost-effective way to create full-color finished labels on demand.

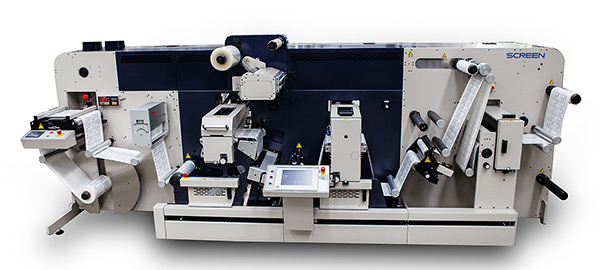

Screen's narrow-web inkjet label-printing system and new finishing line work seamlessly together inline to print, coat, laminate, die-cut, strip waste matrix and rewind finished labels. The result is a comprehensive, integrated solution that adds great value to digital label printing, where shorter run lengths and quicker turnarounds are here to stay.

Screen USA unveiled the JetConverter L350 at the recently concluded Labelexpo Americas 2014 in Rosemont, Ill. As booth visitors watched a variety of digital converting applications in the live technology demonstrations, they could readily appreciate the benefits of single-pass digital printing and finishing.

The JetConverter L350 processes printed label stock at speeds up to 209.9 feet per minute, depending on the type of media and feed volume (repeat length) used. The auto web tension control is capable of handling a wide range of substrates, both paper and non-paper. The touch-screen HMI controls with complete software package preinstalled are mounted on a sliding console for ease of operation.

The JetConverter L350 maximizes automation from label press through to finished product. Standard features include a servo-driven semi-rotary flexographic printing station suitable for flood coating and spot coating. A full-rotary re-registration option is available.

The JetConverter L350's finishing capabilities also include overlaminating for handling laminate with and without carriers, along with super-varnishing and cold foiling. The unit can operate in full-rotary or semi-rotary mode for cold foiling. The semi-rotary die-cutting station is equipped with a 25.5-inch magnetic cylinder for fast and accurate positioning of cutting dies.

In addition, the JetConverter L350 offers a scissor slitting module mounted with lift-out knife shafts (the slitting knives feature automatic setup), back scorer with two knives, twin spindle product rewinder and one-contact waste matrix stripping module with counter-impression roller.

Other advantages, such as decreased setup and adjustment times and reduced paper wastage achieved by a shorter path line, enable the creation of a highly effective label production workflow.