- New series with a total of six new flatbed printers

- New series with a total of six new flatbed printers

- 3 GTF models and 3 larger XTF models with a wide range of applications

- Arizona Flow technology enables zoneless, productive printing without masking

- New flow technology achieves an increase in productivity of about 20

- New high-key print mode with new VariaDot technology enables perfect prints at very high productivity

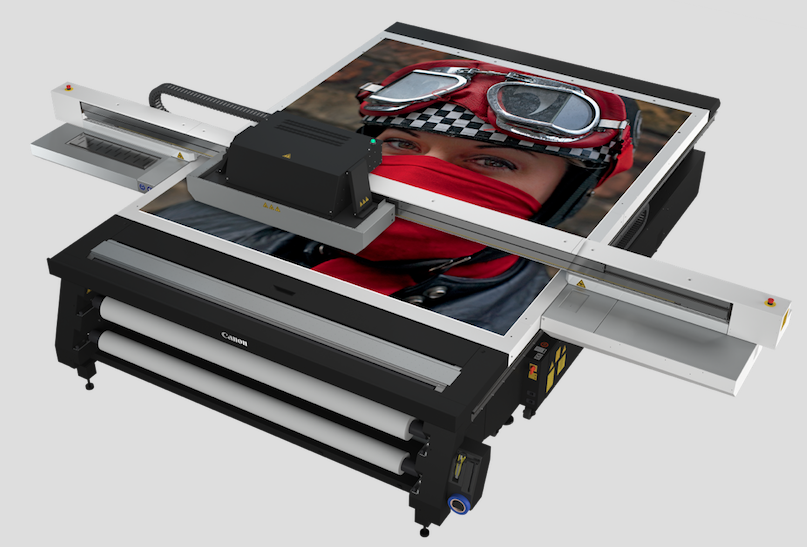

Building on its extensive experience in flatbed printing, Canon today introduces the new Arizona 2300 series. The new Arizona series comprises six models for large-format applications, helping customers accelerate print production, improve operational efficiencies and take advantage of new growth opportunities. Interested parties can view the Canon Arizona 2380 XTF with Roll Media Option worldwide via online and live demos in Canon Customer Experience Centers including Venlo, The Netherlands.

Six powerful printing systems

The new Canon series includes six models in total: the Canon Arizona 2340 GTF, -2360 GTF and -2380 GTF with a 1.25 x 2.5 metre print table size and three larger models Canon Arizona 2340 XTF, -2360 XTF and -2380 XTF with a 2.5 x 3.08 metre print table size.

Smart productivity

The new printer series revolutionises the architecture of flatbed tables, based on a new zoneless airflow intake technology: Canon's new Arizona FLOW technology. The new table design consists of several "FLOW sources", the suction areas. These are combined with easy-to-use pneumatic registration pins to fix the substrate optimally and more precisely. Masking of unused table areas is a thing of the past with the new Flow technology. The result is an increase in productivity of about 20 percent, as no time is needed to mask the free table area. This results in significantly shorter set-up times and faster changeover between jobs. The patented FLOW technology makes printing on unusual and more demanding media such as canvas, wood and glass, or even printing large images tiled across several large panels, easier than ever before. It also means less waste and increased production time.

Pneumatic registration pens allow users to print from edge to edge on the substrate. Substrates can be aligned on either the left or right edge of the table. The Arizona 2300 Series offers exceptional ease of use for double-sided media handling. The integrated work and turn/tumble workflow makes double-sided printing easy with mirrored pins and origins.

Even printing on unusually shaped plates, heavy, smooth or pre-cut media is now no longer a challenge.

Ready for immediate use - thanks to LED UV drying

Preheating times are a thing of the past: Canon's Arizona 2300 series offers immediate operational readiness with its LED UV drying system, enabling faster turnaround of jobs, even at the last minute.

Productivity at an all-time high

Users keep their productivity at an all-time high by printing up to 95 square metres per hour. The automated maintenance system provides printhead maintenance and reduces downtime by restoring nozzle functions in seconds - including white ink, which is normally difficult to maintain. In addition, the highly sensitive camera system allows easy, fast and accurate print head alignment and flatbed table calibration.

With Canon Arizona Xpert, the Canon Arizona 2300 series has a self-learning feature, so that designs for complex, multi-shift projects are recognised by the system and saved as a "recipe". The recognised complex layout print jobs can then be run multiple times and transferred as a recipe to other new projects and jobs. This saves set-up time and automates the production process.

In addition to the Arizona 2300 series, Canon is also introducing the Arizona Xpert Version 2.1 with new functions and many ready-made recipes to increase productivity. The new software is able to print intelligent outlines of the media on the flatbed table for perfect positioning without tape or masks.

The new version 2.1. not only supports many new preconfigured recipes. In addition, an optimal printing and cutting workflow is enabled through integration with the Canon ProCut software. The software also allows the simple exchange of print recipes between print service providers and graphic designers. End products can be called up in a 3D view in the Adobe Creative Suite. This means that design errors can be identified early on.

Sustainable through design

With no warm-up time, the Canon Arizona 2300 saves a whopping 40 percent energy thanks to LED UV curing. It also offers low ink consumption, with an average of less than eight milliliters of ink per square meter. The sustainability concept of the Arizona 2300 series is further underlined by the very long service life of the LED lamp and the standard power supply connection.

The Canon Arizona 2300 series manufactured in Germany has been certified by TÜV and DGUV safety tests. This ensures that the environmental impact is minimized and a safer working environment is guaranteed. The UV inks are "GreenGUARD Gold" certified so that prints are also suitable for use in schools, hotels and hospitals. Of course, there is also traditionally no VOC content in Arizona UV gel inks compared to other current ink technologies.

A new dimension of possibilities

Thanks to the high-key print mode, the compensation of the pixel placement, the improved screening and the award-winning VariaDot printhead technology, users achieve excellent print quality. And this print for print, across a wide range of media and at the highest production speed.

Users looking for the optimal configuration for high-quality, high-margin applications can add additional ink channels four, six and eight, including the most brilliant white ink and clear varnish yet.

The roll media option opens up a wide range of roll media up to 220 centimeters, including thin, heat-sensitive media such as vinyl and very thin film. A simple change between rigid and flexible media jobs is possible at any time, quickly and easily, without having to convert the machine. 24/7 production becomes a reality for secure, unattended overnight printing. For prints on rigid plastic materials such as acrylic, polycarbonate and styrene, an upgrade kit for active static suppression can be added at any time.

New dimension: The Canon Arizona 2300 series can also be equipped with Canon software "Touchstone" for structured relief printing. Applications for interior design, including wallpaper and furniture panels with textured effects, are possible.

Dirk Brouns, Vice President, Large Format Graphics, and Martijn van Hoorn, Senior Vice President Research & Development at Canon Production Printing comment: “The large format graphics market is driven by innovation and we are fully committed to the research and development program of our Canon Arizona flatbed solutions. With the Arizona 2300 series we are introducing a revolutionary new flatbed technology: a unique airflow system that simplifies workflows and accelerates production processes. We look forward to bringing this product to market to open up new growth opportunities for our customers. "

Wouter Derichs, Sales & Marketing Director, Large Format Graphics at Canon Europe: “We are convinced that the new Arizona 2300 Series will enable our customers to increase their profits, expand their application possibilities and open up new market opportunities - always with operational Excellence. With the addition of this new flatbed printer series to our portfolio and in addition to our Colorado UVgel R2R printers, we have a number of large format solutions that meet the requirements of each individual customer. "

www.canon.de