Walki, a leading manufacturer of packaging solutions, will be presenting its extensive product range at FachPack in Nuremberg, Germany, from 24 to 26 September 2019. It comprises sustainable barrier papers and boards, including laminates with certified circular polymers – an important element in Walki’s concept of a “Zero Waste Future”. Walki's customers are active in food service and consumer packaging for example for frozen food, fresh or confectionery products and non-food articles such as detergents, hygiene products, electronics or luxury products. Visitors to FachPack can consult Walki at booth 7A-436.

Walki, a leading manufacturer of packaging solutions, will be presenting its extensive product range at FachPack in Nuremberg, Germany, from 24 to 26 September 2019. It comprises sustainable barrier papers and boards, including laminates with certified circular polymers – an important element in Walki’s concept of a “Zero Waste Future”. Walki's customers are active in food service and consumer packaging for example for frozen food, fresh or confectionery products and non-food articles such as detergents, hygiene products, electronics or luxury products. Visitors to FachPack can consult Walki at booth 7A-436.

Walki continuously develops new innovative barriers for coating of packaging papers or board qualities. Headquartered in Espoo, Finland, the company is gradually replacing conventional petroleum-based barriers with sustainable alternatives, such as Walki-Wood with tall-oil-based barrier or Walki-Bio with PLA coating (PLA= poly lactic acid). "Today, more than 80 percent of our products are made from renewable or recycled raw materials" explains Leif Frilund, President and CEO at Walki. "For some applications, such as the frozen food sector, the proportion is as high as 95 percent. Our goal is to offer all our products to be renewable, recyclable or compostable.

Zero Waste Future: Minimizing waste with product-specific solutions

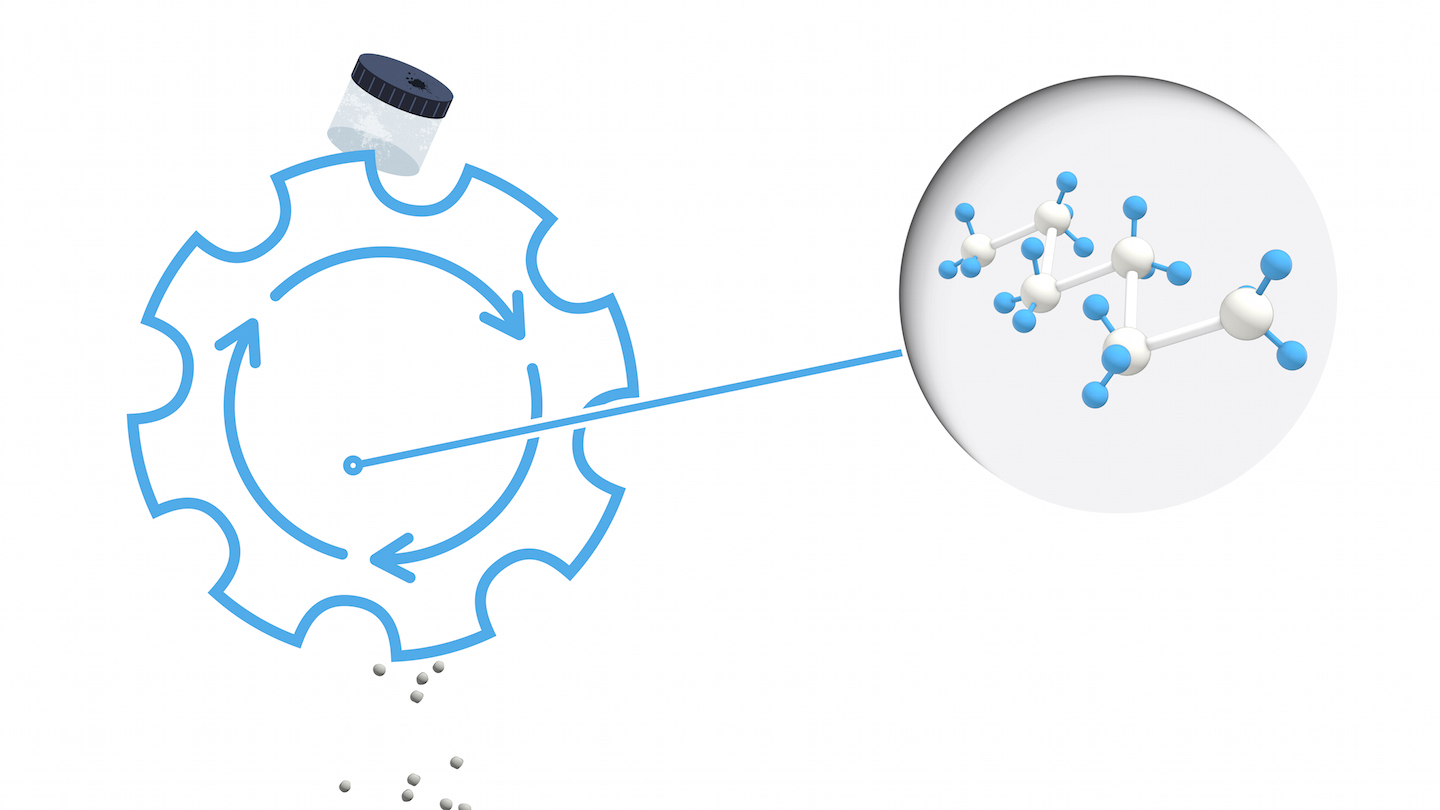

Walki has established a sustainability platform called "Zero Waste Future". With this platform, the company aims to develop specific packaging solutions for its customers' products while minimizing waste in a holistic manner – both for food and for packaging waste. The aim is to keep materials in a cycle by either recycling or composting them. As one of the pioneers, Walki uses certified circular polymers, for example, instead of conventional petroleum-based materials for barrier coatings, thus closing the material cycle. They are manufactured by SABIC, Walki Group’s longtime partner, in an innovative process from low-value, mixed plastic household waste that would otherwise be incinerated or landfilled. Grades with barriers made of certified circular polymers are currently close to market maturity at Walki and are expected to be available on an industrial scale from 2020. Walki will be providing information and advice on this subject and on the overall concept of Zero Waste Future at FachPack.

Dispersion technology offers great potential

Recently, Walki acquired Plastiroll, one of the pioneers and Europe's leading producers of compostable bags and films. With capacities for extrusion coating, film blowing and printing and its portfolio including the well-known Bioska and Hauska brands, Plastiroll is a useful addition to Walki's product range. "Dispersion technology, in particular, is future-oriented and offers great potential for a wide range of applications," says Frilund. "There is still a lot of potential for development here and our R&D department is already working intensively on it.”

www.walki.com