Cameras, light barriers and motion detectors have one thing in common: they work with light sensors, which are already indispensable in many applications. In the future, these sensors could also play an important role in telecommunications by enabling data transmission using light. Scientists from the Karlsruhe Institute of Technology (KIT) at the InnovationLab in Heidelberg have succeeded in taking a decisive step forward in this development: printable light sensors that can see colors. They have now published their results in the journal Advanced Materials (DOI: 10.1002/adma.201908258).

Cameras, light barriers and motion detectors have one thing in common: they work with light sensors, which are already indispensable in many applications. In the future, these sensors could also play an important role in telecommunications by enabling data transmission using light. Scientists from the Karlsruhe Institute of Technology (KIT) at the InnovationLab in Heidelberg have succeeded in taking a decisive step forward in this development: printable light sensors that can see colors. They have now published their results in the journal Advanced Materials (DOI: 10.1002/adma.201908258).

New technologies will increase the demand for optical sensors for a wide range of applications, including Visible Light Communication (VLC). VLC uses interior lighting in buildings for optical communication. This technology offers a number of advantages in terms of security, speed and accessibility compared to current transmission methods such as WLAN or Bluetooth. "Our research contributes to this technology by combining the advantages of a special type of material, namely organic semiconductors, and their production with printing techniques," says Dr. Gerardo Hernandez-Sosa of the KIT Lighting Technology Institute, one of the authors of the publication.

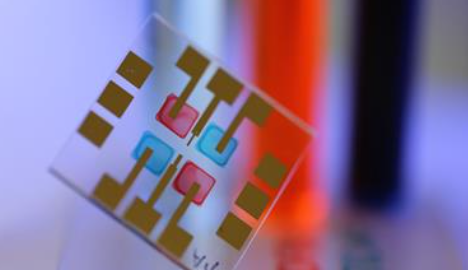

Semiconductors are the basis of computers, smart phones, solar cells, and many other technologies. Some semiconductor materials react to light by changing their conductivity and the light intensity can be measured as electric current. Within this class of materials, there are also some that can be applied to a substrate with a printer, like printer ink. These materials react to different wavelengths and can therefore distinguish colours. The team led by Hernandez-Sosa has now succeeded in finding a material composition that is suitable for use as a wavelength-sensitive light detector and can also be printed on flexible carriers. This means that areas ranging from very small to very large can be printed. The layout can be easily designed using a computer. "These photo sensors can be produced in large quantities in any design on flexible, lightweight materials. This makes them particularly suitable for mobile devices," says lead author Noah Strobel.

The printing of semiconductor devices is a relatively recent development, but their potential for future applications is very high. The industry is already investing heavily in the production of printed OLED displays for televisions and smartphones. Printed flexible solar cells or pressure sensors are also already on the market. The production of printed light detectors has also already reached industrial level. Chances are therefore high that these elements will be used in many applications in the future, especially in view of the growing demand for sensors in the Internet of Things, in smart cities and in Industry 4.0.

www.kit.edu