The migration behaviour of digital ink systems plays a decisive role in the selection of a digital printing press and largely determines which application segments the printing system can cover - and to which segments it could be extended if required. These comprehensive aspects of migration-optimised solutions are considered in Xeikon's new white paper, in which Lode Deprez, Vice President Technology, provides answers to which criteria must be taken into account when deciding which digital printing system to buy.

The migration behaviour of digital ink systems plays a decisive role in the selection of a digital printing press and largely determines which application segments the printing system can cover - and to which segments it could be extended if required. These comprehensive aspects of migration-optimised solutions are considered in Xeikon's new white paper, in which Lode Deprez, Vice President Technology, provides answers to which criteria must be taken into account when deciding which digital printing system to buy.

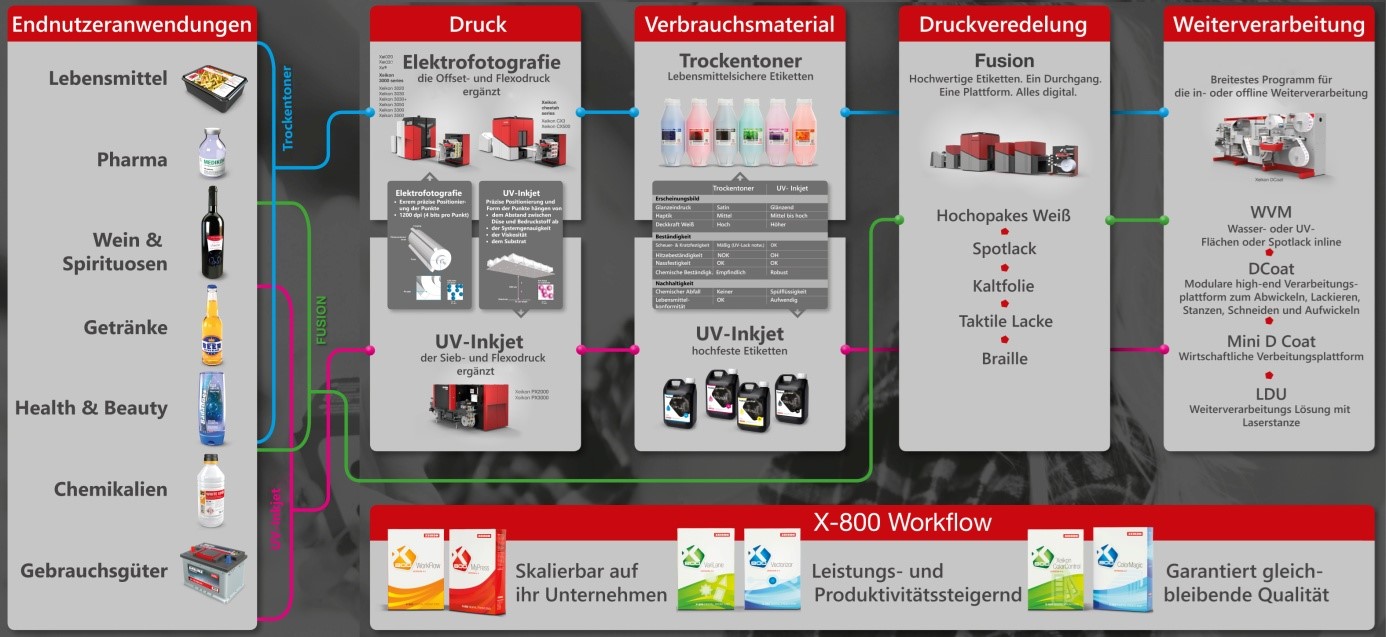

"Different applications require different solutions. Since Xeikon has a portfolio for digital printing that is unmatched in the market, it can provide the optimal solution for every user," says David Reiser, Sales Manager L&P DACH Digital Solutions.

The white paper first answers the question why there cannot be the "one" ink system that suits all applications in digital packaging printing. It shows the extremely complex requirements for ink systems, which differ in their migration behaviour and whose food safety is a very important criterion for the selection of a machine system.

In addition, the ink systems used must meet the legal requirements. With a brief overview of the most important regulations of legislation, associations and brand manufacturers, the white paper provides information in an easy-to-understand manner about the migration limits that apply today.

Against this background, it shows how great the influence of the chemical composition of digital ink systems is on migration behaviour. By discussing the different compositions of dry and liquid toners as well as UV inkjet inks, it highlights the advantages of each ink system for different applications.

But not only ink components with their different molecular sizes have an influence on the migration behaviour of digital ink systems. The mass transfer of inks to foodstuffs depends on other factors such as storage time, storage temperature, barrier properties of the packaging material and ultimately, quite decisively, on the packaged goods themselves. The white paper also provides clear explanations of these factors.

As a conclusion, a clear picture emerges in which user segments the digital ink systems have their strengths. Divided into the segments of food, pharmaceuticals, wine & spirits, beverages, health & beauty, chemicals and consumer goods, individual recommendations can be derived for each label and packaging printer, depending on the composition of the portfolio, which will be of clear assistance to him in his decision for a digital printing system. This also refers to the question of what to do if the portfolio is to be further developed in a certain direction.

www.xeikon.com