Innovative new folding arm significantly reduces footprint and shortens cycle times versus comparable Epson robots -

Innovative new folding arm significantly reduces footprint and shortens cycle times versus comparable Epson robots -

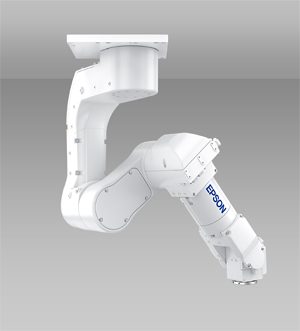

Seiko Epson Corporation (TSE: 6724, "Epson") has developed a new series of 6-axis (vertically articulated) industrial robots. The robots in the new N series have an innovative folding arm* that will allow them to be installed in very limited spaces. The first product in the series is scheduled for global release in May 2016. Epson will demonstrate an N series robot at the International Robot Exhibition 2015, which will run from December 2-5, at Tokyo Big Sight (the Tokyo International Exhibition Center).

Soaring labor costs and more stringent accuracy requirements for a growing number of sophisticated, complex products have been spurring demand in recent years for robots in the assembly of smartphones and a wide variety of other electronics products. However, conventional automation solutions take up considerably more space than would a person performing the same task. Manufacturers want robots that can be installed in small spaces and deliver high throughput. The N series delivers on both fronts.

The structure of the new arm maximizes the space efficiency of the N series, enabling these robots to be installed in an area as small as 600 mm square, the equivalent of the space occupied by a human worker. These robots reduce cycle times and provide higher throughput because the arm will not collide with the base or other objects when folded, so fewer moves are needed to avoid collisions with objects in the surroundings. In addition, reduced adjustment and teaching times mean shorter robots setup times.

"Epson is committed to automating production floors around the globe with high-performance industrial robots like the new N series that leverage Epson's original robotics technologies," said Yoneharu Fukushima, chief operating officer of the Robotics Solutions Operations Division. "We are committed to meeting customer expectations and contributing to manufacturing innovation by providing the market with the robotics products it needs, strengthening our customer support through a global network of sites, and providing total solutions."

The features of the N series make these robots ideal for the assembly and inspection of electronic products, electronic components, and automotive components, as well as for medical applications in the markets of Europe, America, and Greater China. They can be used to automate countless tasks, such as screw tightening, component insertion, material handling, and the loading of products in test systems.

* The first ever to be installed on a 6-axis robot (based on Epson research as of October 2015).

www.epson.com