Wear on the spindle in ball screws can be continuously monitored and evaluated with an intelligent system from KIT

Wear on the spindle in ball screws can be continuously monitored and evaluated with an intelligent system from KIT

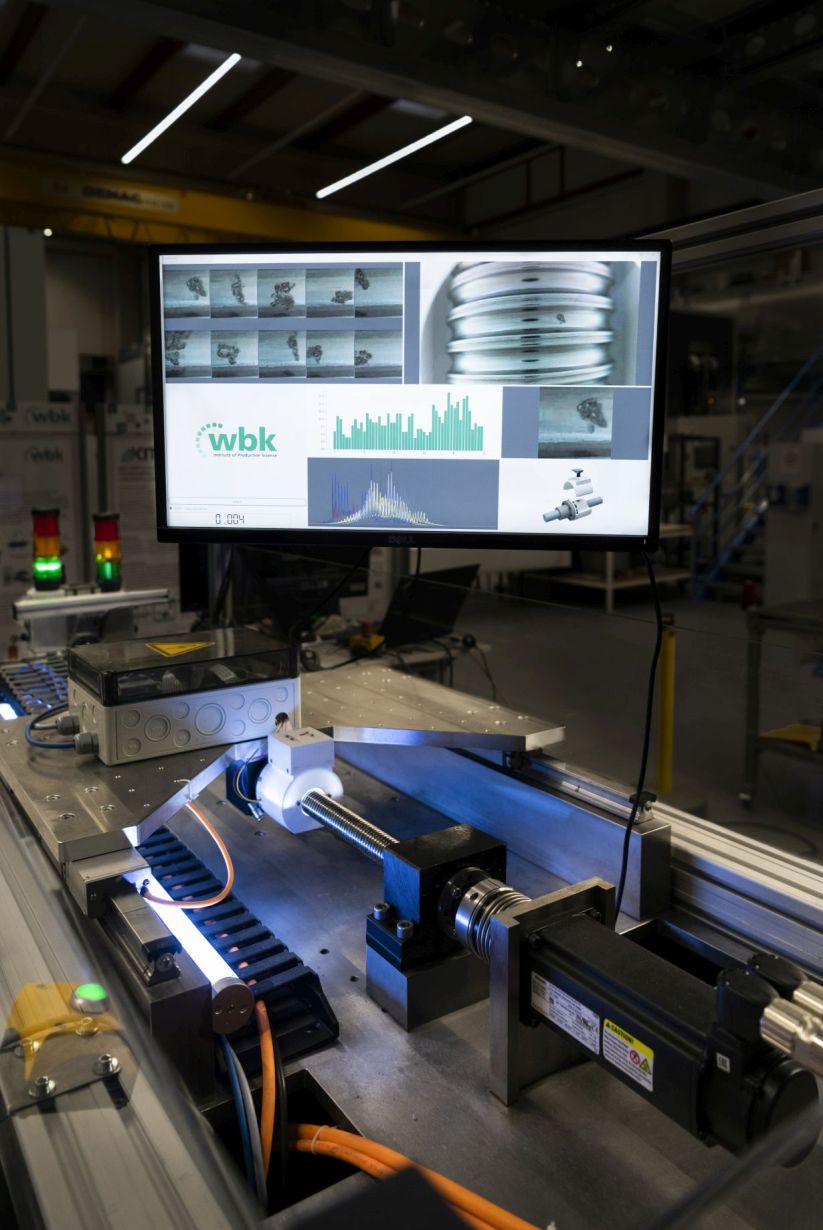

Researchers at the Karlsruhe Institute of Technology (KIT) have developed a system for fully automatic monitoring of ball screws in machine tools. A camera integrated directly into the nut of the ball screw is used. Based on the image data generated in the process, an artificial intelligence (AI) continuously monitors wear and thus reduces machine downtime.

The maintenance and timely replacement of defective components in machine tools is an important part of the production process in mechanical engineering. In the case of ball screws, such as those used in lathes for precision guidance in the production of cylindrical components, wear has so far been detected manually. "Maintenance is therefore associated with assembly work. The machine then stands still for the time being," says Professor Jürgen Fleischer from the Institute of Production Technology (wbk) at KIT. "Our approach, on the other hand, is based on the integration of an intelligent camera system directly into the ball screw. This allows a user to continuously monitor the condition of the spindle. If there is a need for action, he is automatically informed."

The new system consists of a camera with illumination attached to the nut of the ball screw, which is combined with artificial intelligence to evaluate the image data. As the nut moves on the spindle, it takes individual pictures of each spindle section. This means that the entire surface of the spindle is analysed in each case.

Artificial intelligence for mechanical engineering

The combination of image data from ongoing operation with machine learning methods enables users of the system to directly assess the condition of the spindle surface. "We have trained our algorithm with thousands of images so that it can now confidently distinguish between spindles with defects and those without," says Tobias Schlagenhauf from wbk, who helped develop the system. "By further evaluating the image data, the wear can also be precisely quantified and interpreted. This allows us to distinguish whether discolouration is simply dirt or whether it is harmful pitting." When training the AI, all conceivable forms of visually visible degeneration were considered and the functionality of the algorithm was validated with new image data never before seen by the model. The algorithm is suitable for all use cases in which image-based defects on the surface of a spindle are to be identified and can also be transferred to other use cases.

{youtube)gWreeIF6NIo{/youtube}

www.kit.edu