For more efficiency, safety and sustainability

For more efficiency, safety and sustainability

Sustainability has different facets in the paper industry: On the one hand, paper products are an important substitute for plastics; on the other, companies are part of one of the most energy-intensive industries. With the software-based solution EnergyOpt Paper from airinotec, the paper industry can produce more sustainably, more efficiently and under better working conditions. The tool has now been significantly expanded once again - and is already in use in its new form by the first customers.

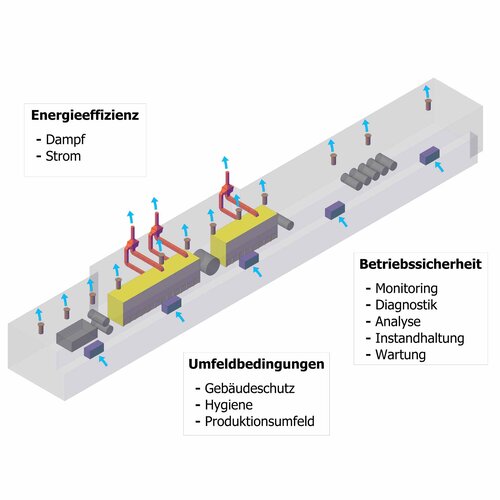

Air handling systems are of great importance in the paper industry. It is therefore all the more astonishing that the control possibilities are only partially exploited. As a rule, the systems are designed for the bad point: Heat and steam are dissipated in such a way that the plant operates under the most difficult conditions. The systems are regulated once at commissioning and are either not regulated at all or only set for summer/winter changeover. The consequence: Cold air ingress can lead to condensation and mould formation. The energy consumption is higher than necessary for both the ventilation systems and the heat recovery systems.

This is where the product from airinotec comes in: With EnergyOpt Paper, paper producers can adapt their plant systems to the respective conditions. The software solution can be integrated into existing or new process control systems and enables a quick return on investment at low investment costs. On the one hand, the control options considerably reduce energy costs; on the other hand, the risk of mold growth is reduced and a hygienic production environment is created. This enables companies in the paper industry to push ahead with their sustainability policy and save costs at the same time.

The extension of EnergyOpt Paper enables an online determination of the air and water balance. This type of analysis avoids the original problem of taking a snapshot. Usually, the plants are only measured in a specific mode of operation on site. By additionally installed measurement technology sensors and the input from EnergyOpt Paper, much more information can now be collected under a wide range of production conditions and climatic requirements. The software records the existing data, writes measurement reports and calculates and evaluates the information. On this basis, the air flows and the air balance are optimized. Since the system provides information on the condition of the plants, the online analysis also increases operational reliability. Deviations and malfunctions are detected at an early stage and can be corrected promptly.

The further development of EnergyOpt Paper has been extensively tested and is already in use at a leading international paper producer.

www.airinotec.com