RICOH 3D for Healthcare Recognized for Advancing Community Access to Patient-Specific 3D-printed Anatomic Models

RICOH 3D for Healthcare Recognized for Advancing Community Access to Patient-Specific 3D-printed Anatomic Models

The EXT 220 MED is the new name for the Kumovis R1 as part of our growing extrusion printing class of printers. This platform is a game-changer in medical device manufacturing, enabling 3D printing of implants and instruments using high performance polymers such as PEEK and Radel® PPSU. Now, thanks to the ingenuity of our engineering teams, we are excited to announce a performance upgrade to allow up to 30% faster throughput.

The EXT 220 MED is the new name for the Kumovis R1 as part of our growing extrusion printing class of printers. This platform is a game-changer in medical device manufacturing, enabling 3D printing of implants and instruments using high performance polymers such as PEEK and Radel® PPSU. Now, thanks to the ingenuity of our engineering teams, we are excited to announce a performance upgrade to allow up to 30% faster throughput.

6K’s UniMelt process allows end-of-life and out-of-spec parts to be profitably re-used with a vastly reduced environmental footprint.

6K’s UniMelt process allows end-of-life and out-of-spec parts to be profitably re-used with a vastly reduced environmental footprint.

6K Additive, a division of 6K Inc., announced today that it has entered into an agreement with Australia-based Surgical Metal Recycling Pty Ltd (SMR). The companies will explore a shared mission to transform the metals supply chain in Australia, including revolutionizing the way surgical implants are treated at the end of their useful life.

Additional anatomic regions provide more surgeons with access to diagnostic, patient-specific 3D printed models

Additional anatomic regions provide more surgeons with access to diagnostic, patient-specific 3D printed models

Ricoh USA, Inc. today announced RICOH 3D for Healthcare – a HIPAA-compliant, ISO 13485 certified 3D medical manufacturing center for the development, design and production of 3D-printed anatomic models – has received 510(k) clearance from the U.S. Food and Drug Administration (FDA) for new areas of patient-specific anatomic modeling for diagnostic use, including cardiovascular, neurological, gastrointestinal, genitourinary, and breast applications.

VESTAKEEP® i4 3DF is the world’s first implant-grade filament based on PEEK for use in medical 3D printing of human surgical implants

VESTAKEEP® i4 3DF is the world’s first implant-grade filament based on PEEK for use in medical 3D printing of human surgical implants

Curiteva’s world’s first 3D printed spinal implants for commercial use are based on Evonik’s VESTAKEEP® i4 3DF biomaterial filament

Combination of Curiteva’s technology and Evonik’s cutting edge material offers the possibility of enhance integration and healing for spinal surgery

Joint development and commercialization agreement will initially focus on development of bioprinting solution for CollPlant’s regenerative breast implants, addressing $2.6 billion market opportunity

Joint development and commercialization agreement will initially focus on development of bioprinting solution for CollPlant’s regenerative breast implants, addressing $2.6 billion market opportunity

Stratasys’ P3 technology-based bioprinter and CollPlant’s rhCollagen-based bioinks also ideal for future innovation and production of additional human tissues and organs

Companies to cross-promote respective bioprinting products

Collaboration increases access to 3D-printed anatomic models for hospitals and clinics.

Collaboration increases access to 3D-printed anatomic models for hospitals and clinics.

Stratasys Ltd. (NASDAQ: SSYS), a leader in polymer 3D printing, announced today it has signed an agreement with Ricoh USA, Inc. to provide on-demand 3D-printed anatomic models for clinical settings.

J5 MediJet 3D printer’s multi-material, multi-color capabilities enable surgeons to produce realistic models to plan complex surgical procedures, improving planning, training and patient outcomes

J5 MediJet 3D printer’s multi-material, multi-color capabilities enable surgeons to produce realistic models to plan complex surgical procedures, improving planning, training and patient outcomes

France-based Regional University Hospital of Brest (CHU de Brest) is witnessing substantial improvements in pre-surgical planning procedures following the implementation of a new 3D printer by Stratasys’ partner-reseller, Cylaos.

In this video, Dr. Gijs van Hellemondt and Dr. Maarten Spruit from the Sint-MaartensKliniek in Nijmegen perform hip revision surgery on a 60-year-old rheumatoid patient who has had several surgeries on both sides. The surgeons used the personalized Materialise aMace implant system for this complex revision case.

In this video, Dr. Gijs van Hellemondt and Dr. Maarten Spruit from the Sint-MaartensKliniek in Nijmegen perform hip revision surgery on a 60-year-old rheumatoid patient who has had several surgeries on both sides. The surgeons used the personalized Materialise aMace implant system for this complex revision case.

Over 20 years ago, OrthoView formed under a collaborative spirit that has survived to this day. With this attitude, they have developed innovative features driven by surgeons' need for joint replacements, trauma, and spine procedures. In this blog, we'll go over a few formative moments in the development of OrthoView.

Over 20 years ago, OrthoView formed under a collaborative spirit that has survived to this day. With this attitude, they have developed innovative features driven by surgeons' need for joint replacements, trauma, and spine procedures. In this blog, we'll go over a few formative moments in the development of OrthoView.

Brinter® Bioprinting Solutions include over 60 3D-printed parts using HP Multi Jet Fusion technology, making up 75% of all the custom-made medical equipment 3D parts found in the machine.

Brinter® Bioprinting Solutions include over 60 3D-printed parts using HP Multi Jet Fusion technology, making up 75% of all the custom-made medical equipment 3D parts found in the machine.

Introduction

Brinter®, a trailblazing Finnish bioprinting company, provides comprehensive 3D bioprinting solutions and services for the MedTech industry.

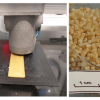

Brinter has been developing the granulate-based multi-material 3D printing process as part of the EU Horizon2020 project Novum. The increased concern of environmental issues and technology development has led to growing interest in developing novel, sustainable, yet high-performance materials for industrial additive manufacturing (AM) and for a wide variety of applications such as electrical insulation components and parts for the automotive, marine and medical industry. AM enables rapid and cost-effective manufacturing of complex and lightweight parts without any expensive tools such as moulds.

Brinter has been developing the granulate-based multi-material 3D printing process as part of the EU Horizon2020 project Novum. The increased concern of environmental issues and technology development has led to growing interest in developing novel, sustainable, yet high-performance materials for industrial additive manufacturing (AM) and for a wide variety of applications such as electrical insulation components and parts for the automotive, marine and medical industry. AM enables rapid and cost-effective manufacturing of complex and lightweight parts without any expensive tools such as moulds.

Andreas Falk, COO of Erler Zimmer, an expert company in anatomical model-making, discusses the use of 3D printing and how it has helped revolutionise their industry.

Andreas Falk, COO of Erler Zimmer, an expert company in anatomical model-making, discusses the use of 3D printing and how it has helped revolutionise their industry.

Historically, the use of cadavers has been paramount in the effective teaching of anatomical science and medicine. How better to understand anatomy than to dissect and examine that of a real body, however, in recent years it has become apparent that 3D printing holds the potential to revolutionize medical education.