Titan Tough Epoxy 85 brings world-class durability, dimensional accuracy, and repeatability to industrial additive manufacturing production.

Titan Tough Epoxy 85 brings world-class durability, dimensional accuracy, and repeatability to industrial additive manufacturing production.

Inkbit is also showcasing the Inkbit Vista™ AM System during Formnext.

Inkbit is set to unveil Titan Tough Epoxy 85, its latest additive manufacturing material, at Formnext. Specially formulated for durability, this material delivers enhanced performance for applications that require both high accuracy and production-grade mechanical properties. This material is the latest addition to the Inkbit Vista ecosystem and was developed in response to customer requests for parts that are tough, accurate, and designed for AM, which typically means intricate geometries.

In addition to Titan Tough Epoxy 85’s debut, the Inkbit Vista™ AM system is set to make its first appearance at Formnext, promising to inspire show visitors to explore new opportunities in mass production. Powered by Vision-Controlled Jetting (VCJ) for accurate and repeatable parts, the Inkbit Vista™ system offers dimensional accuracy and production scale throughput with Inkbit’s range of functional and robust materials.

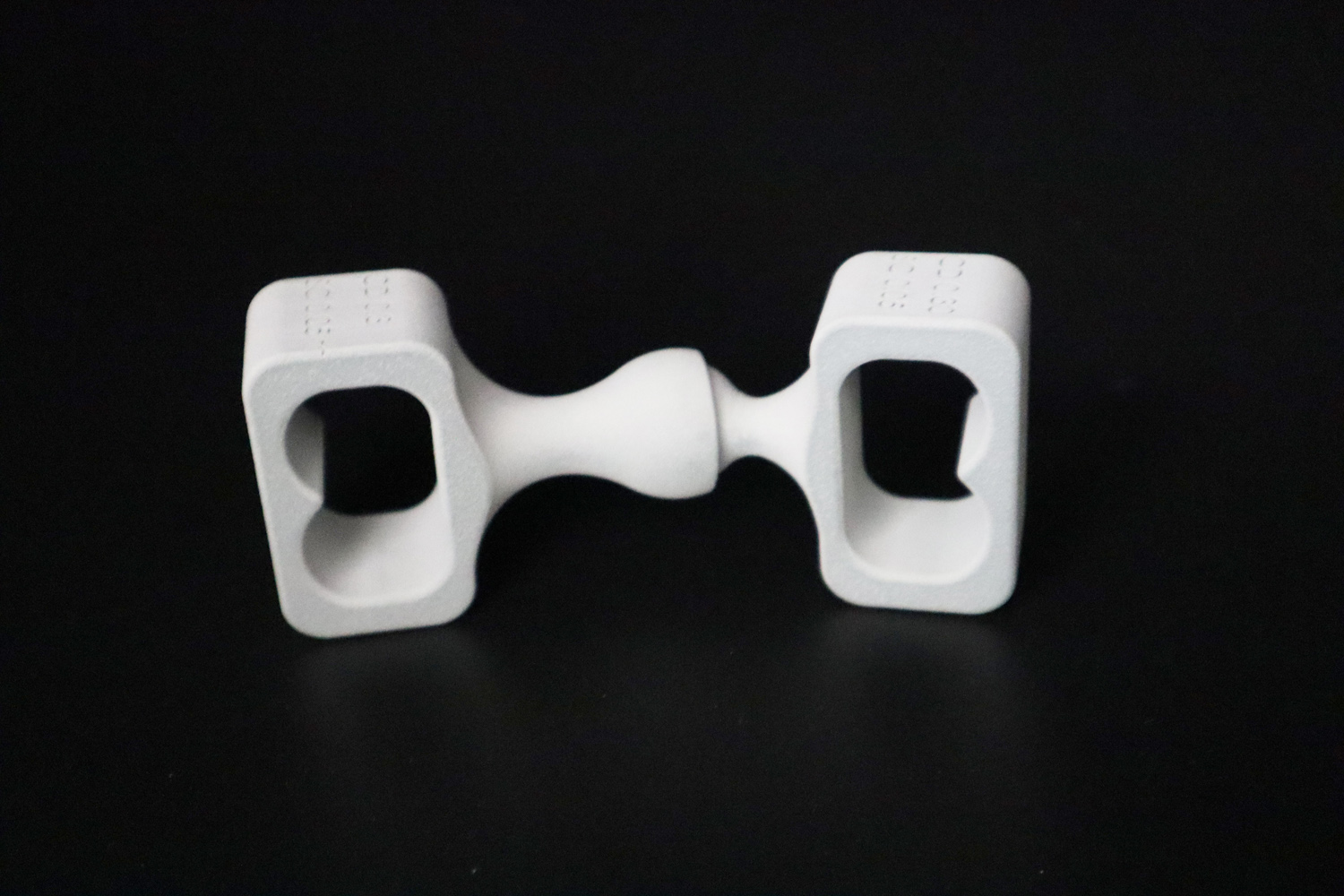

Conceived with advanced chemistry and the expertise of the Inkbit materials science teams, Titan Tough Epoxy 85 is specifically formulated to be impact-resistant and withstand long-term UV exposure. With the precise dimensional performance delivered by the Inkbit Vista™ platform, this material is suited to multi-component designs where tolerance stack-up challenges require individual components to be accurate, so assemblies fit together.

Inkbit has also developed simple, low-labor post-processing with an automatable workflow that uses wax support material which melts away, enabling the system to print complex, highly detailed part geometries reliably. The support material is also recyclable – contributing to Inkbit’s low cost-per-part advantage. This clean production process further reduces the requirement for a dedicated production environment with tight environmental controls.

Inkbit Co-Founder and CEO Davide Marini looks forward to meeting new customers at Formnext, stating, "The launch of our Titan Tough Epoxy 85 is an important milestone in our journey to take material jetting from the realm of prototyping to that of production. The toughness, tensile strength, impact resistance and flexibility of Titan Tough Epoxy 85 rival those of Nylon 12, today’s AM industry standard. The new classes of materials we are introducing, when combined with the multi-material capabilities and accuracy of our platform, will enable a formidable acceleration in product development and digital manufacturing across many industries. We would like to invite Formnext visitors to visit our booth, see our printer, and take home as many sample parts as they wish," adds Marini.

Inkbit's participation at Formnext, between November 15 through 18th, provides an excellent opportunity for visitors to explore the latest advancements in production AM technology, with the high throughput and complex geometries achievable with the Inkbit Vista™ platform. The experts at Inkbit will be present in hall 12.1, stand F39 to show how the technology can be applied in industries such as automotive, healthcare, aerospace, robotics and consumer goods.

www.inkbit.com