World premiere at drupa – the new Peak Performance generation of the Speedmaster XL 106

World premiere at drupa – the new Peak Performance generation of the Speedmaster XL 106

Autonomous printing now possible in packaging production, too

Improved operating concept and cluster production help alleviate the skills shortage

New dryer uses up to 30 percent less energy – and can pay for itself in just two years

Digital innovations with Prinect replace multiple work steps

Competitiveness: Up to 20 percent higher productivity significantly cuts costs for print shops

Competitiveness: Up to 20 percent higher productivity significantly cuts costs for print shops Modular logistics for medium and large-format Rapidas

Modular logistics for medium and large-format Rapidas Graphco, RMGT’s Exclusive Distributor for 9, 7, 5, & 3 Series Presses in the Midwest and Southeast, will install an RMGT 970ST-5+CC+LED (5 Color with Coater) press at BRD Printing in Lansing, Michigan. The award-winning commercial print firm employs more than 30 full-time employees who produce high-quality brochures, catalogs, and magazines in their 28,000-square-foot plant which operates 16-20 hours per day.

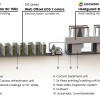

Graphco, RMGT’s Exclusive Distributor for 9, 7, 5, & 3 Series Presses in the Midwest and Southeast, will install an RMGT 970ST-5+CC+LED (5 Color with Coater) press at BRD Printing in Lansing, Michigan. The award-winning commercial print firm employs more than 30 full-time employees who produce high-quality brochures, catalogs, and magazines in their 28,000-square-foot plant which operates 16-20 hours per day. DG press, a leading manufacturer of hybrid web offset presses, proudly announces the game-changing capabilities of their DG-AUXO press series. In response to the growing demand for sustainable packaging solutions, DG press has developed a cutting-edge printing and coating platform for the food packaging industry designed to enhance the properties of mono-material packaging by applying functional coatings while simultaneously applying printed graphics and varnish in one pass.

DG press, a leading manufacturer of hybrid web offset presses, proudly announces the game-changing capabilities of their DG-AUXO press series. In response to the growing demand for sustainable packaging solutions, DG press has developed a cutting-edge printing and coating platform for the food packaging industry designed to enhance the properties of mono-material packaging by applying functional coatings while simultaneously applying printed graphics and varnish in one pass. GE Richards, Graphco and Print & Finishing Solutions, the Exclusive Distributors for all RMGT 9, 7 and 5 Series Presses sold in the United States announce that RYOBI MHI Graphic Technology Ltd. (RMGT) will exhibit at drupa 2024 in Dusseldorf, Germany for 11 days from Tuesday, May 28 thru Friday, June 7. Under the theme “Assist Your Potential with Technological Expertise and Constant Innovation,” RMGT’s exhibits and demonstrations will focus on two major concepts: “Increased productivity for commercial printing through autonomous operation,” and “Further automation for package printing.”

GE Richards, Graphco and Print & Finishing Solutions, the Exclusive Distributors for all RMGT 9, 7 and 5 Series Presses sold in the United States announce that RYOBI MHI Graphic Technology Ltd. (RMGT) will exhibit at drupa 2024 in Dusseldorf, Germany for 11 days from Tuesday, May 28 thru Friday, June 7. Under the theme “Assist Your Potential with Technological Expertise and Constant Innovation,” RMGT’s exhibits and demonstrations will focus on two major concepts: “Increased productivity for commercial printing through autonomous operation,” and “Further automation for package printing.” To support an ambitious strategy and build a strong future, the newly created IGR Group invested in a Komori offset press: the GL 37-inch, 5-color H-UV Led with a flexo coating unit.

To support an ambitious strategy and build a strong future, the newly created IGR Group invested in a Komori offset press: the GL 37-inch, 5-color H-UV Led with a flexo coating unit. Komori Europe proudly announces a new distribution agreement with SIMPEX, marking a significant milestone in advancing printing technology across the Kingdom of Saudi Arabia. This partnership extends beyond the mere distribution of new Komori printing presses and includes comprehensive services and parts support, elevating the printing landscape in the region.

Komori Europe proudly announces a new distribution agreement with SIMPEX, marking a significant milestone in advancing printing technology across the Kingdom of Saudi Arabia. This partnership extends beyond the mere distribution of new Komori printing presses and includes comprehensive services and parts support, elevating the printing landscape in the region. Presentation of innovations in sustainability and technologies

Presentation of innovations in sustainability and technologies Invicta I2 running at 300 meters per minute on 12-micron PE material.

Invicta I2 running at 300 meters per minute on 12-micron PE material. Komori will exhibit at drupa 2024 in Düsseldorf, Germany after an eight-year hiatus. During these eight years, the speed of social change has increased, consumption patterns have shifted, and outlooks have undergone significant transformations.

Komori will exhibit at drupa 2024 in Düsseldorf, Germany after an eight-year hiatus. During these eight years, the speed of social change has increased, consumption patterns have shifted, and outlooks have undergone significant transformations. India’s largest multinational flexible packaging and solutions company, is participating in PlastFocus 2024, and will feature its advanced machine technology at Booth No. A 51, Hall 1, at Yashobhoomi (IICC), Dwarka, New Delhi from February 1-5, 2024. Recognized as an ideal platform for the plastics and packaging sector, PlastFocus 2024 will feature UFlex's state-of-the-art machine technology, primed to redefine industry standards.

India’s largest multinational flexible packaging and solutions company, is participating in PlastFocus 2024, and will feature its advanced machine technology at Booth No. A 51, Hall 1, at Yashobhoomi (IICC), Dwarka, New Delhi from February 1-5, 2024. Recognized as an ideal platform for the plastics and packaging sector, PlastFocus 2024 will feature UFlex's state-of-the-art machine technology, primed to redefine industry standards.