Market leaders supply the first polypropylene (PP) for industrial additive manufacturing; joint development of new applications for major customers; joint go-to-market initiatives to expand the market and exploit opportunities for sustainable market impact

- BASF, the world's leading chemical company, is working with technology leader HP to advance manufacturing through innovative new materials, the joint development of advanced applications with market-leading customers and go-to-market initiatives

- First industrial-grade sustainable polypropylene (PP) developed for the HP Jet Fusion 5200 3D Printing System to accelerate manufacturing by providing the best performance/cost ratio

- By jointly developing new PP applications, these material innovations enable first-time partners such as Extol, Forecast 3D, Henkel, Oechsler, Prototal and others to achieve unprecedented levels of profitability, speed up their design process and produce high-quality 3D printed parts faster

- Cooperation enables joint commitment to sustainable production and the development towards a low-carbon recycling economy

DOMO Chemicals-ZARE partnership strengthens 3D-printed parts proposition

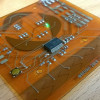

DOMO Chemicals-ZARE partnership strengthens 3D-printed parts proposition New multi-layer PCB boosts electronics rapid prototyping

New multi-layer PCB boosts electronics rapid prototyping 3D printing is nothing new in itself. REHAU has been dealing with the possibilities associated with it for quite some time. This process offers great potential, especially for products manufactured in small batches. Now, thanks to a special printer from Israel, the company is going one step further and enabling 3D printing of electrical components.

3D printing is nothing new in itself. REHAU has been dealing with the possibilities associated with it for quite some time. This process offers great potential, especially for products manufactured in small batches. Now, thanks to a special printer from Israel, the company is going one step further and enabling 3D printing of electrical components. With 852 exhibitors and 34,532 visitors, an increase of more than 8,000 visitors compared to the previous year, Formnext has become the leading trade fair for everything to do with additive manufacturing. The Frankfurt exhibition halls were packed from morning to night, with many visitors finding more than just inspiration for future projects and lively discussions, especially about materials. From Sabine Slaughter

With 852 exhibitors and 34,532 visitors, an increase of more than 8,000 visitors compared to the previous year, Formnext has become the leading trade fair for everything to do with additive manufacturing. The Frankfurt exhibition halls were packed from morning to night, with many visitors finding more than just inspiration for future projects and lively discussions, especially about materials. From Sabine Slaughter New METHOD Carbon Fiber Editions Print Metal Replacement Parts with High Strength and Accuracy

New METHOD Carbon Fiber Editions Print Metal Replacement Parts with High Strength and Accuracy Planning continues with an updated health concept and added virtual offerings

Planning continues with an updated health concept and added virtual offerings Enhanced the production line dedicated to 3D Printing

Enhanced the production line dedicated to 3D Printing Opening a New Dimension for Large-Format 3D-Printing in the Automotive & Consumer Products Industries.

Opening a New Dimension for Large-Format 3D-Printing in the Automotive & Consumer Products Industries. Operates using a first-of-its-kind rotational printing platform, maximizing print reliability and offering greater output from a small footprint

Operates using a first-of-its-kind rotational printing platform, maximizing print reliability and offering greater output from a small footprint MakerBot Continues to Rapidly Expand Industrial-Grade Materials for the METHOD Platform

MakerBot Continues to Rapidly Expand Industrial-Grade Materials for the METHOD Platform