With 852 exhibitors and 34,532 visitors, an increase of more than 8,000 visitors compared to the previous year, Formnext has become the leading trade fair for everything to do with additive manufacturing. The Frankfurt exhibition halls were packed from morning to night, with many visitors finding more than just inspiration for future projects and lively discussions, especially about materials. From Sabine Slaughter

With 852 exhibitors and 34,532 visitors, an increase of more than 8,000 visitors compared to the previous year, Formnext has become the leading trade fair for everything to do with additive manufacturing. The Frankfurt exhibition halls were packed from morning to night, with many visitors finding more than just inspiration for future projects and lively discussions, especially about materials. From Sabine Slaughter

For everyone who is involved in additive manufacturing, there is a mandatory appointment every autumn: The Formnext in Frankfurt. As in the past years, all those who have rank and name in the industry, new suppliers as well as service companies from almost all industrial sectors met on the four days of the fair. Additive production is no longer limited to one or a few industrial applications but affects all areas - from raw materials, manufacturing, production, production, presentation, installation and the final end piece or even the entire piece. Dedicated software, generative design and a wide variety of materials are used. In addition, skilled workers must be trained and found, especially since previous training and study courses have only limited or no access to these new technologies.

Especially in the field of materials there was and still is a deficit. The variety of applications means that special materials and material mixtures are needed for a wide variety of projects or components. While different alloys are used in conventional manufacturing, for example in the area of metal or metal parts, in additive manufacturing these must first be available, tested and then certified. Since the production conditions for printing components are different, the design of components using AI, AI and other software developments is usually easier and more effective - with the functionality being the same or better - other material mixtures/alloys or other materials with sometimes better stability, strength and durability are quite often the choice. And all this under the premise that material savings are also made - and not only waste is meant. It is quite possible that a generatively designed product saves more than 50 percent of material. Since these components can usually not be manufactured with conventional production methods or only with great difficulty, additive manufacturing is usually the only solution to produce more effectively, economically and ecologically. In addition, there are different additive manufacturing methods. This alone increases the demand for different materials.

In the following we will introduce some of the highlights of Formnext.

Henkel

The Loctite division presented a new photoreactive material, together with Origin. This photopolymer material meets UL 94V-0 fire, smoke and toxicity safety standards and the industry's leading 12- and 60-second vertical fire tests for aerospace applications when used with Origin One printers. The innovative product sets a new threshold for fire, smoke and toxicity resistant 3D printing materials in many industries, including aerospace, automotive and transportation.

"The development of our new fire-resistant material is a true breakthrough innovation that surpasses the properties of all currently available materials for DLP systems on the market," said Philipp Loosen, Head of 3D Printing at Henkel. "Our open material platform has been specially developed to enable a wide range of our resin portfolio to be used in additive mass production. Together with Origin, we have demonstrated our ability to harness the transformative power of 3D printing for industrial manufacturing.

Origin's technology enables the printing of many different types of chemicals through world-class hardware, environmental control and software tools to fine-tune the printing process. Using programmable photopolymerization (P³) technology, the company can precisely adjust light, temperature and other conditions to automatically optimize prints in real time for the best possible results. "Since our founding, we have been committed to an open approach to materials," said Origin's CEO, Chris Prucha. "We have been able to program Origin One to meet the environmental conditions required for the material to cure, activating Henkel's innovative chemistry to create 3D printed parts that set a new standard for fire resistance." Expansion of the Loctite material platform

Expansion of the Loctite material platform

The company also announced a further expansion of the open Loctite material platform. To this end, a cooperation agreement was concluded with Rapid Shape, a supplier of high-speed technologies for additive manufacturing. Both companies intensively tested Henkel's high-performance materials on Rapid Shape's industrial I30+ 3D printers. The combination of materials and machine solutions enables 3D printing of high-quality parts for a wide range of applications. For example, Henkel's ultra-clear Loctite 3D 3820 resin enables customers in the healthcare and other industries to produce transparent high-performance parts for visual flow testing, covers and lenses.

Together, we want to further develop, evaluate and drive forward 3D printing solutions tailored to applications in the mass production of additive manufacturing in all industries. Loctite 3D 3820 demonstrates the power of our open material platform. We offer our customers the flexibility to choose the right material for their application and to work with the right printers in the Henkel ecosystem such as Rapid Shape's I30+," said Philipp Loosen.

6K

The developer of microwave plasma technology for the production of innovative materials used in additive manufacturing (AM), lithium-ion batteries and other industrial markets introduced the new powder Onyx In718. "We see our mission as providing more attractive business opportunities for developers and users of additive manufacturing parts. Higher performance powders play a crucial role in this," said Dr. Aaron Bent, CEO of 6K. "The nickel alloy 718, which is used particularly in the aerospace industry and other industrial markets, is the perfect alloy to demonstrate the unique capabilities and strengths of 6K's powder manufacturing process. We present powders and parts from subtractive manufacturing by turning and powders regenerated after selective laser melting".

Sustainable production of powders

In addition, another 15 metal alloys were presented, which were all produced with the microwave-based UniMelt plasma system. Based on raw material sources of recycled alloys in combination with the plasma system, powders with better properties are produced. These powders have a higher sphericity, have no porosity, are free from satellites and have excellent flowability and high tap density. Onyx In718 is the first product in the Onyx series of premium powders that have higher performance and can be produced from certified sustainable sources. "6K powders offer a compelling value proposition for customers and 3D printing service providers," said Dr. Youping Gao, CEO of Castheon, a U.S.-based leader in R&D services and comprehensive, innovative additive manufacturing solutions. "With 6K's onyx powders, we are achieving greater strength and elongation than ever before. In addition, after heat treatment an isotropic grain structure with almost isotropic properties (XY and Z direction) can be produced, which is very exciting".

The Onyx In718 material underpins two aspects of 6K's strategy to offer powders for additive manufacturing from sustainable sources. Firstly, they are developed from turnings with certified chemicals and secondly from regenerated or recycled used powders for additive manufacturing. In the future, 6K plans to expand its strategy to include materials produced from additive manufacturing support structures, non-conforming 3D printed parts and other input materials.

With its metal recovery technology, 6K can target the powder size distribution for the required AM process, including L-PBF (Laser Powder Bed Fusion), EBM (Electron Beam Melting), DED (Direct Energy Deposition), Binder Jetting or MIM (Metal Injection Moulding). As a result, the UniMelt process has a yield of almost 100 percent - i.e. a yield that is 3 to 4 times higher than gas atomisation.

BigRep

The most attractive exhibit at the stand of the Berlin-based manufacturer of large-format additive production printers was LOCI, a functional design prototype of an autonomous, electrically powered vehicle. This was printed using BigRep's DNATM technology, which is enabled by the Studio G2 and PRO printers and also processes new materials such as PLX, PET-CF, PA6/66 and BVOH. "We are pleased to once again be at the forefront of the cross-industry exploitation of the full potential of AM applications with the presentation of the LOCI prototype and other industrial prototypes with Bosch Rexroth, AIRBUS and Dassault Systèmes," said Martin Back, BigRep Managing Director. "With our large-format 3D printers and new technical-grade materials developed jointly with BASF, we are expanding the capabilities of our additive systems to enable advanced applications and efficient workflows that add value to businesses. Together, our AM solutions enable industrial production in aerospace, automotive, rail and many other industries."

Different prototypes possible

The fully autonomous electric podcar LOCI, specially conceived and designed as a "last minute transport solution" in urban environments by the company's own NowLab, can be equipped with different superstructures for its field of activity. Unique prototypes or small series of LOCI can be produced locally on demand without additional costs, supplier dependency or long lead times. This eliminates the need for large warehouses and remote production facilities, while simplifying logistics and reducing transportation. Developed using parametric modeling, LOCI takes full advantage of AM's potential and limitless flexibility. The design of the podcar can be easily adapted to a specific location or application; it adapts the handling purpose, materials, structural properties, special tires for different terrains, custom branding and integrated solar energy.

Comprehensive NFC capability

In fact the formnext showcase captures three different LOCI iterations: The Berlin LOCI model presented is a one-person campus commuter with a slim design, touchscreen media display, surround sound audio, wireless phone/device store, integrated LED lighting, TPU airless tires and integrated BigRep Part DNA technology. The San Francisco LOCI is a rendering concept version for urban commuting. Its slim body can maneuver in traffic, a single right-hand door lifts to protect exiting passengers from rain, and it has two passenger seats. Finally, the Dubai LOCI is a render concept version for airport traffic with high-end luxury feel, solar panels, luggage compartment and robust tires for desert weather.

LOCI's BigRep Part DNATM technology is based on NFC chips embedded in the 3D printed parts. This chip can be scanned with a mobile device to identify the part. In the future, it can also be integrated with sensors to monitor part condition and provide maintenance or replacement information - simply scan the part and print a replacement.

LOCI was built from only 14 individual parts and measures 85cm x 146cm x 285cm, with the largest part measuring 1000 x 600 x 700 mm. All parts were printed with a BigRep PRO, BigRep Studio G2 or BigRep ONE Additive System. The bodywork was printed with BigReps PRO HT as the airless tyre designers chose TPU, the bumpers were printed with PLX and the carriers and joints with PA6/66.

Other exhibits included aircraft seats, which were generatively designed and printed with new materials, much lighter than their conventionally manufactured counterparts, while also minimizing costs. Farsoon

Farsoon

The company presented new laser sintering machines and partnerships. Among them is the FS301M, a metal system which was developed and optimized in cooperation with an American aerospace customer for high quality production and easy operation. The machine is equipped with one or two lasers. The two-laser version ensures high productivity and performance and operates on a footprint of 30 x 30 square centimeters, with full coverage of the area. Many industry-specific features, such as the new dust filter with a service life of approx. 1500 operating hours, reduce the manufacturing costs per part; the small footprint of the machine enables a higher area yield in series production while at the same time providing flexibility when changing powder.

The manufacturer's fastest and most open plastic laser sintering machine, Flight-HT403P, is capable of producing parts with fine details and wall thicknesses of less than 0.3 millimeters. The name "Flight" Technology was developed from the powerful laser source - installation of a 500W fiber laser instead of a 100W CO2 laser - and is therefore the basis for this innovation. With its ultra-fast scanning speed, it enables 2 builds of production per day.

Also on the booth was the FS421M, a Continuous Additive Manufacturing System (CAMS) for metals. The printer, designed for aerospace applications, offers high part quality, automated powder feeding and cartridge operation.

The HT1001P offers high repeatability for the production of plastic parts. In automated operation the operating effort is reduced. Parts of one meter size could be viewed at the booth. After completion of the beta phase at FKM and Modellbau Kurz, the printer is now commercially available.

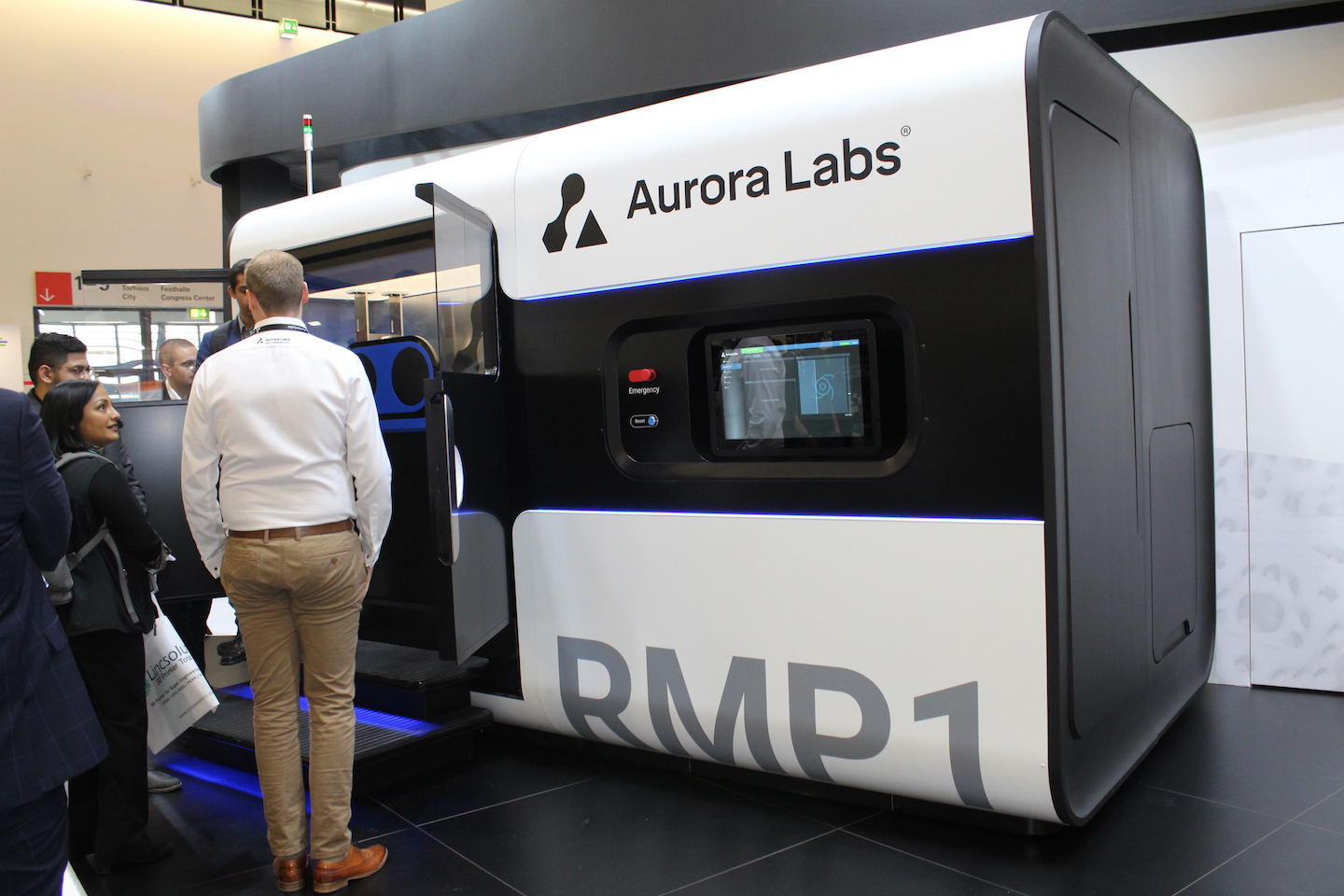

Aurora Labs

The Rapid Manufacturing Printer One (RMP1) from Aurora Labs is the world's first Direct Metal Laser Melting (DMLM) 3D printer with Multilayer Concurrent Printing (MCP) technology. Aurora's patented MCP technology enables the direct additive manufacturing of metals at much higher speeds than previously possible with established single-layer DMLM technology.

The RMP1 has a large construction volume of ø450 x 400 millimetres, several lasers with different power options. The MCP technology enables the multi-laser system to work over several powder layers in parallel, multiplying the laser application time and productivity compared to DMLM systems not equipped with MCP.

The advantage of combining MCP technology with DMLM technology is the decreased requirement for furnace treatments compared to MIM technologies, which helps to achieve higher quality production of complex geometries produced with additive metal manufacturing.