The design and converting of reels, webs, and sheets into labels, pouches, cans, cartons, and more is nothing without the partners that help keep packaging businesses operating at the top of their game.

The design and converting of reels, webs, and sheets into labels, pouches, cans, cartons, and more is nothing without the partners that help keep packaging businesses operating at the top of their game.

The art of successfully manufacturing packaging is nuanced and involves a number of processes and stakeholders.

There is of course the designers and artworkers who bring your ideas to life, then the colour specialists and machine minders who make it all real, using substrates formulated by experts in the art of manipulating polymers, fibres, and ores.

But in today’s increasingly complex and challenging operating environment, any number of additional stakeholders are intrinsic in the successful delivery of packaging projects and the longevity of the manufacturing business that operate in the market.

That’s one reason why anyone in the packaging supply chain should get themselves along to the NEC in Birmingham on 12 & 13 February 2025 for the next instalment of Packaging Innovations & Empack.

There you’ll find a comprehensive selection of solutions and services that will help the packaging supply chain perform at its best today and for the foreseeable future.

Sustainable compliance

Given the current climate and move to sustainable and circular business models, it is perhaps no surprise that those companies offering services to help packaging businesses achieve their ESG goals and other sustainability-minded corporate initiatives will have a heavy presence at Packaging Innovations & Empack 2025.

Aura (B72) combines consultancy and technology to deliver pioneering, sustainable packaging solutions. Whether strategic planning and life cycle assessments (LCAs), or colour and artwork management. Aura has a number of solutions to suit the markets needs. Its offer also includes e-halo, a technology platform to drive real-time decision-making using live accurate data to manage compliance and ensure alignment with global packaging legislation, whilst reducing environmental impact.

Beyondly Global (C74) is an environmental compliance scheme and consultancy, which works with businesses to help them become more confident about their environmental choices – from meeting compliance obligations, excelling in managing environmental data, and achieving the sustainability expectations of stakeholders, and beyond.

CarbonQuota (B70) has a stated mission to simplify carbon measurement and reduction, so helping businesses to help the planet. Automated carbon footprint technology and tailored reduction strategies enable companies to efficiently and effectively measure, report, and actively reduce their environmental impact. Its carbon calculators use a rich dataset of emission factors and are aligned to international carbon standards, constantly updated, and fully automated to provide accurate footprints, instantly.

Ecosurety (F46) provides a compliance scheme committed to accelerating change towards a sustainable world. Through broad collaboration, it enables businesses to make sustainable product and packaging decisions. Ecosurety further supports efficient and transparent investment in UK recycling projects through improved infrastructure, innovation, and consumer awareness campaigns.

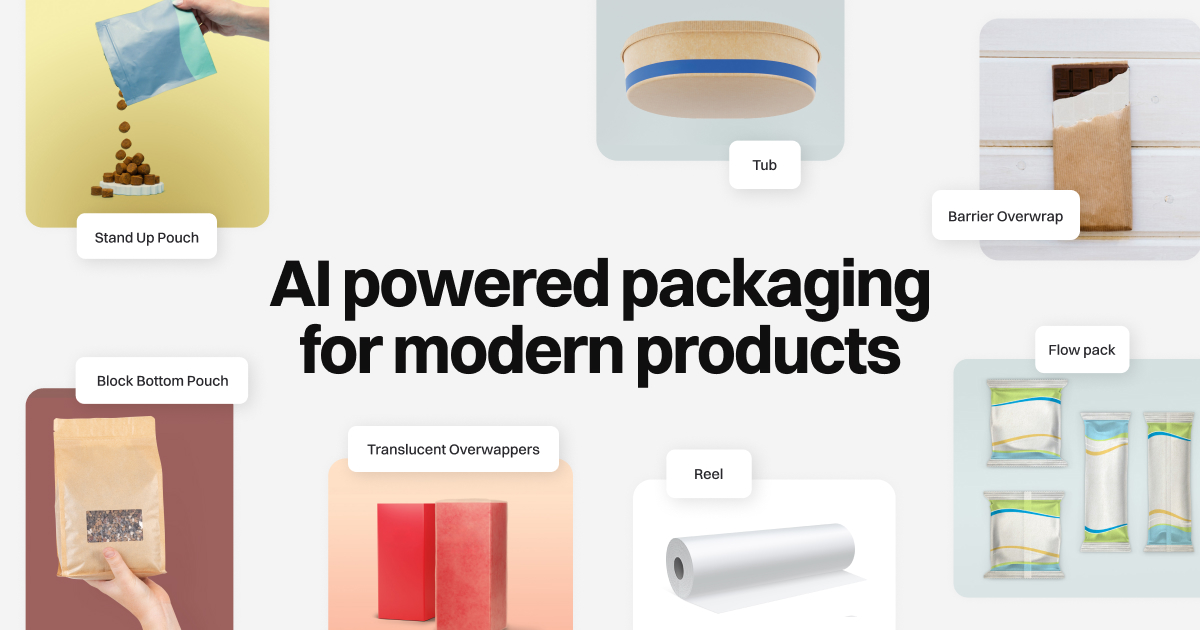

Embracing the rise in Artificial Intelligence (AI), one.five (B12) is a business that combines different facets of the modern packaging landscape and uses AI to optimise product functionality, manufacturing efficiency, global regulatory obligations and cost control. This includes costs and profitability, material options and barrier characteristics, machinability and scalability, and compliance with waste infrastructure and local regulations, to deliver what it claims is, “the ultimate modern packaging solution”.

Valpak (C84) manages the recycling obligations of over 5,000 UK businesses under producer responsibility laws. its services are focused around packaging, WEEE, and batteries, both in the UK and internationally. Other services include environmental consultancy, waste management and supply chain transparency.

Wastepack Group (P92) has over two decades of experience as producers’ expert compliance partner, with extensive knowledge of packaging and WEEE compliance, alongside other related environmental issues and legislation such as WEEE collections, extended producer responsibility (EPR), and the Plastic Packaging Tax.

Management and fulfilment

For those seeking more practical solutions, there are a number of options to choose from out of the exhibitors at Packaging Innovations & Empack 2025.

Moisture and humidity remain important considerations at each step of the packaging manufacturing supply chain. Specifically, stable environmental conditions, which includes relative humidity, in storage, production and/or processing facilities help maintain product and machinery in optimum condition, thereby reducing static, dimensional instability of paper and other hydroscopic materials, and improving processes such as bottling and labelling. A specialist in this area is Humidity Solutions (U54), which was established in response to the market’s need for a dedicated specialist in humidity control. As the UK’s leading independent distributor, it selects the highest quality humidifiers and dehumidifiers from the best manufacturers around the world, including Vapac in the UK, Neptronic in Canada, Cotes in Denmark, and HiDew in Italy. This allows it to supply equipment that is reliable and suited to the application at hand.

This is as humidity has an impact on almost all types of material, whether plastics, paper, metal, or even glass. As such, keeping humidity under is essential both for the package and for the product inside. To this end, Munters (V42) provides energy efficient dehumidification and climate control solutions. Across a wide range of industries that includes food, pharmaceutical, and automotive, its solutions create precise and controlled indoor climate conditions to ensure the best quality product or environment.

Summit Systems (Q79) is then on hand to handle and process waste and scrap from the manufacture of plastic packaging. With over 25 years in the recycling trade, a dedicated team operating across the UK buys and sells scrap plastic with a commitment to cradle-to-cradle service. Extensive expertise in plastic grades ensures full traceability and ethical treatment of materials. Also offered is a comprehensive toll buy-back service, encompassing efficient sorting, advanced processing techniques, and customised solutions to transform unused or surplus polymer materials into high-quality recycled pellets or compounds.

Charles Kendall (Q60) is a complete, end-to-end supply chain management group. From shipping classic cars to transporting T-rex and triceratops fossils, the group offers a number of services that add up to a conclusive solution to supply chain management challenges. Compliance and logistics knowhow are complemented by Charles Kendall being a registered member of Amazon’s Solution Provider Network, as well as an appointed EU clearance agent. This means it is a trusted and reliable partner for the outsourced Fulfillment by Amazon (FBA) shipping service. FBA allows sellers to outsource order fulfilment to Amazon, whereby picking, packaging and shipping of orders to customers is handled directly by the e-commerce giant. All the seller needs to do is get their products to an amazon Fulfilment Centre, which is where Charles Kendall comes in.

Among the services offered by Complete Co-Packing Services (R62) is dedicated warehousing and fulfilment that provide picking, packing and dispatch services for e-commerce businesses. The benefits of third-party fulfilment services include cost efficiency through the reduction of overhead expenses and scalability to accommodate variable demand. The company’s e-commerce fulfilment services cater for a wide range of businesses operating in the personal care, cosmetic and home care markets, as well as food and drink, pet supplies, and packaging materials.

To help finance the packaging sector, R&D tax credit specialist randd uk (P78) has helped thousands of UK businesses successfully claim back millions of pounds using the R&D Tax Credits Incentive. With a 100% success rate and an average first claim of £50,000, the company has claimed back over £250 million in tax credits for its clients, including those within the packaging sector.

The above highlights the range of solutions and services to be presented at Packaging Innovations & Empack 2025, and why the event is a must-attend for all in the packaging supply chain regardless of their job role or priority.

Registering online for the free-to-attend two-day exhibition is highly recommended as the 12 & 13 February event nears and upwards of 7,000 likeminded attendees prepare to descend on the NEC Birmingham.

www.packaginginnovations.com