"3D Additive Manufacturing is the creation or fabrication of almost any part, component or product mold that a business or manufacturer could require, all products are printed (sintered) onsite negating the need to have to obtain a third party to forge your component. The limits are now limitless...Costing for Fabrication drastically reduced. "

"3D Additive Manufacturing is the creation or fabrication of almost any part, component or product mold that a business or manufacturer could require, all products are printed (sintered) onsite negating the need to have to obtain a third party to forge your component. The limits are now limitless...Costing for Fabrication drastically reduced. "

Fonon Technologies, one of the leaders in Laser Material Processing (laser marking, 3D Engraving, Cutting and Scribing) entered into the Additive Manufacturing sector with its advanced 3D Metal Printing Technology. Fonon's Fusion™ High Precision 3D Additive Manufacturing Equipment is now available to consumers.

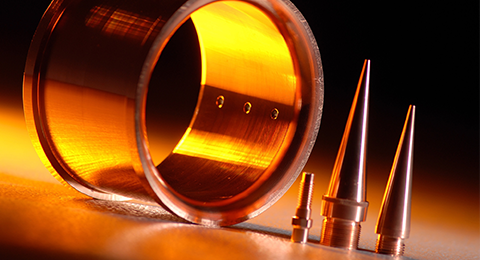

Fonon Additive Manufacturing Technologies encompass 3D FUSION TECHNOLOGY or 3D Laser Metal Sintering (Commonly known as 3D Metal Printing or Selective Melting) Technologies. The technology creates products layer by layer – after a layer's particles are sintered together the next layer is added and the process is repeated thousands of times. It enables geometries not previously possible to be manufactured. Full-form parts are made directly from computer-aided design (CAD) data for a variety of industrial, medical, military, commercial and other applications.

STATE OF THE ART

Advanced 3D Printing Process

Starting with a CAD file that conveys information about how the finished product is supposed to look, the CAD file is then sent to a specialized printer where the product is created by the repeated laying of finely powdered metals to gradually build the finished product.

METAL SINTERING

Perfection Layered

Since it works in a similar fashion to an office printer laying ink on paper, this process is often referred to as 3D printing. The 3D printers can create a vast range of products, including parts for use in airplanes and automobiles, to replacing aging or broken industrial equipment, or for precise components for medical needs.

Product Prototypes

Additive Manufacturing significantly reduces the traditional trial-and-error process – so new products can enter the market more quickly

Eliminate Traditional Constraints

A limitation of subtractive manufacturing is that part designs are often comprised due to the constraints of the subtractive process. 3D Printing enables the design and materialization of objects by eliminating traditional manufacturing constraints

Our 3D Additive Manufacturing equipment constructs and creates metal components or parts directly from a technical CAD drawing or similar document and is capable of recreating geometrically challenged and complicated shapes and components using this method of forging. components created using direct-metal-printing greatly increase productivity and minimize wait times for parts or moulds to be produced. The financial aspect is also greatly reduced primarily due to this new process of creating parts or components using the 3D Additive Manufatiuring process as opposed to the conventional method of outsourcing production to a third party

BENEFITS OF USING THE 3D FUSION MODEL BY FONON

Extremely Quick Part Production

Due to the incredible ease now of being able to print, design and forge parts instantaneously, the design to development stage is more fluid and precise than ever before

Minimal Fabrication Time

This digitally controlled print process gives you the ability to ensure better production plan capacity which in turn allows you to forecast accurate delivery dates and times for the product you are printing.

Low Material Production cost

A smaller footprint is acheived because although the machinery required electricity to function, the powder used in the sintering process is relatively affordable.

Unlimited array of Shape and Component printing options

The scope of part manufacture is unlimited. Incresed product designs and prototypers are acheived with ease resulting in better products and larger rewards.

Dramatically Incresed Supply chain Proficiency

tThe Primary Benefit is the introduction of design files to be utilised in the production and construction of parts. This process eliminates time wasted between a 3D printing company and the company requesting the part to be processed.

Highly Sustainable

The Additive Manufacturing process allows for real time access and analysis of products or parts further increasing time and costings relating to the manufacture.

Easily Accessible

Fonon's 3D FUSION™ comprising of am additive NANO Powder Manufacturing Technology has a firm presence in the medical industry as well as Manufacturing (Mold fabrication and Repair), Defense, aerospace and high technology engineering and electronics sectors.

Minimal Waste

3D Laser Metal Printing is a layered, digitally driven additive manufacturing process that uses high quality focused laser energy to fuse metal NANO powders into 3D objects. Less waste compared to traditional manufacturing methods is not only a cost saving feature of 3D printing but also a possible eco-friendly attribute

www.fonon.com