Products made from renewable raw materials are the focus of many companies. But often the extraction and processing of the material that is taken from nature for this purpose is not at all environmentally friendly. Some results seem to be more greenwashing than real sustainability. Not so with the family business Bags by Riedle from Langenbrettach. Since the product launch of the advertising bag made of grass paper, the paper bag specialist has already received two awards for the extraordinary model from the RIEDLE Nature product line.

Products made from renewable raw materials are the focus of many companies. But often the extraction and processing of the material that is taken from nature for this purpose is not at all environmentally friendly. Some results seem to be more greenwashing than real sustainability. Not so with the family business Bags by Riedle from Langenbrettach. Since the product launch of the advertising bag made of grass paper, the paper bag specialist has already received two awards for the extraordinary model from the RIEDLE Nature product line.

But what are actually the special features of grass paper and why is sustainability so true here? Grass is the fastest renewable raw material that can be used for a paper bag. From the moment it is mowed until the product is finished, the grass is almost ready for harvesting. However, the availability is still limited because the grass cuttings mainly come from otherwise unused compensation areas, which as biotopes may only be mowed 2-3 times a year. This benefits agriculture. The use of compensation areas enables additional sources of income and thus supports employment in rural areas.

Bees also love grass paper. Together with flowers and herbs, the grass used for this grows on wild meadows, free of pesticides and fertilizers. The meadows are located in the native biosphere area of the Swabian Alb, also called permanent grassland. Late mowing promotes biodiversity and thus protects the bees. Furthermore, the grass has already grown so high at this time that it can no longer be used for animal feed.

However, in order for the grass paper to be used as material for a bag and to withstand the usual load when filled, the grass pulp is mixed with approx. 60% wood pulp or waste paper. Nevertheless, the figures for the manufacturing process are impressive in terms of the eco-balance:

97% energy saving: only 136 kWh per tonne compared to approx. 5,000 kWh per tonne of wood pulp. 75% less CO² emissions during raw material production.

99% water saving: Industrial water consumption less than 2 litres per tonne of grass fibre pulp compared to over 6,000 litres of water per 1 tonne of paper for wood fibre pulp.

100% elimination of process chemicals: Dissolution of the stiffening agent lignin in the grass fibre is eliminated. The lignin is contained in the wood fiber and serves to strengthen the wood. For the production of other papers, the lignin must be released chemically in a complex process.

And how does the raw material get into the factory? Long transport routes are of course taboo here. On average, the production of grass pulp requires a distance of 4,000 km, whereas the grass pulp from Baden-Württemberg requires only a few hundred kilometres.

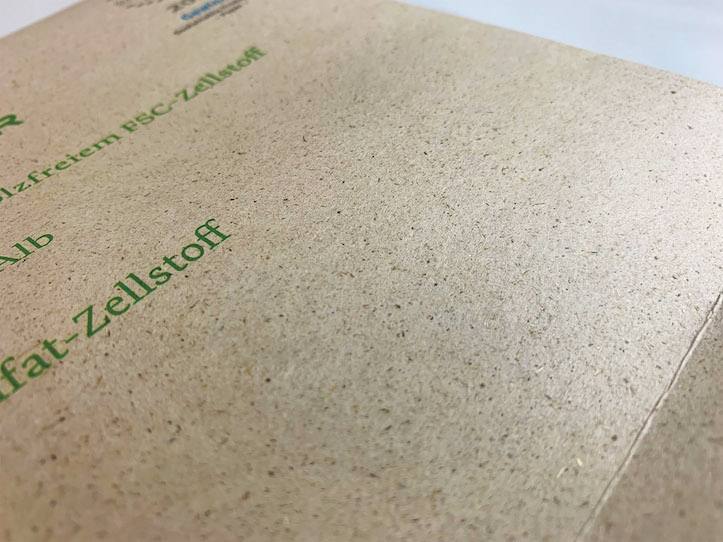

Uniquely multi-sensory: The unique structure of the grass paper not only creates a haptic and optical highlight; the typical grass smell remains in the bag for some time before it is used as a brand and image ambassador.

It is therefore not surprising that the innovative paper bag specialist and managing director of the company, Volker Riedle, has combined these properties with his strict quality requirements to create a reusable paper bag of the highest sustainability quality.

Since its market launch, the "Advertising Ambassador from the Willow", as the trade magazine WA-Nachrichten titled it, has already received two awards. At the Promotional Gift Award 2019, the RIEDLE Nature model made of grass paper convinced the jury. The Promotional Gift Award is an international prize for haptic advertising. In the previous year, the bag made of grass paper was awarded in the category "Sustainable Product" at the PSI Sustainability Awards. These are much more than just product awards. They comprehensively acknowledge that

advertising media not only have a lasting effect, but are also an expression of corporate social responsibility.