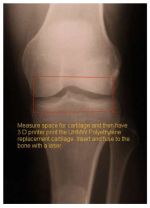

Using current imaging technology, get measurements of the cartilage space in the joint. Then with a 3 D printer, print the replacement cartilage our of ultrahigh molecular polyethylene (or similar wear resistant polymer). After printing the replacement cartilage, insert it in the joint and fuse to the bone with laser.

This should be able to be done with a small incision and not injuring the ligaments/tendons around the joint.

As 3D printers evolve to allowing printing of various alloys of metals, metal replacement cartilage could become the standard for wear resistance and durability.

This would save major surgery for replacement implants as used today.

Submitted by Marvin Christensen, Baton Rouge, LA, USA

http://www.createthefuturecontest.com/