FUJIFILM Europe GmbH (President, Masato “Mark” Yamamoto) has continued its commitment to take a lead on green issues through adopting new Fujifilm Group wide environmental measures and revised emissions-related targets, in a bid to accelerate Fujifilm’s climate change initiatives and impact.

FUJIFILM Europe GmbH (President, Masato “Mark” Yamamoto) has continued its commitment to take a lead on green issues through adopting new Fujifilm Group wide environmental measures and revised emissions-related targets, in a bid to accelerate Fujifilm’s climate change initiatives and impact.

Last week, FUJIFILM Holdings Corporation updated its environmental targets for Fiscal Year ending March 2031 (FY2030). The target to reduce the global Fujifilm Group’s carbon dioxide (CO2) emissions across the entire product lifecycle has been raised from 30% to 45% compared to the FY2013 level. This target has been certified as being WB2°C (well below 2°C) by the international environmental initiative Science Based Targets initiative for being scientifically based to meet the “2°C goal” of the Paris Agreement. The target to contribute to a reduction in CO2 emissions in society by providing low-emissions products and services has been raised from 50 million tons to 90 million tons.

In Europe, the production process of Fujifilm’s main manufacturing site in Tilburg, The Netherlands, a producer of photo paper, offset plates and membranes, has operated completely (100%) on wind energy since 2016. The five wind turbines that have been on site in Tilburg since 2011 generate around 20% of the electricity. The rest of the green energy for the site is produced via wind turbines in the Netherlands and Belgium. This, amongst other measures that include a number of other Fujifilm operations in Europe being powered by 100% renewable energy, has had a dramatic impact on Fujifilm’s carbon dioxide (CO2) emissions, seeing 50% decrease when compared to FY2013, beyond global company targets.

Commenting, Peter Struik, Executive Director, FUJIFILM Europe GmbH and President, FUJIFILM Manufacturing Europe B.V., said:

As part of economic measures implemented in response to the spread of COVID-19, there is a global call to kick-start a green recovery and build a sustainable society through our everyday actions.

Amidst this trend, by revising our global emission-related targets upwards – and continuing to demonstrate our leadership on environmental issues in Europe by going above and beyond global company targets, I hope that we show that we are serious about continuing to contribute to society in green and sustainable way.

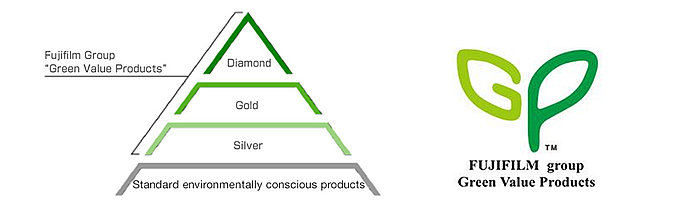

Fujifilm Group has also further committed to new targets for environmentally conscious products and services by considering environmental impacts in the process of developing these products and services. Products and services that aim to significantly reduce environmental impacts are certified as Fujifilm Group “Green Value Products” and FUJIFILM Holdings has introduced a new group-wide target to bring the sales ratio of “Green Value Products” to 60% of the group’s total sales also by FY2030.

The criteria for “Green Value Products”, designed in compliance with ISO14021, include addressing climate change, recycling resources, reducing environmental risks such as the use of hazardous substances, and reducing waste. The program defines group-wide certification ranks (Diamond, Gold and Silver) and has certified 140 items since 2018.

Rank Certification criteria

Diamond Products and services that drastically reduce environmental impact by utilizing innovative technologies

Gold Products and services that reduce environmental impact at the highest level among their respective industries

Silver Products and services that reduce environmental impact at a higher level than their respective industries' standard

Example products and services certified as FUJIFILM Group “Green Value Products”

“SUPERIA ZE-N” (Diamond)

Using this product omits the development process on a newspaper production press, which involves the use of harsh alkaline chemicals, water and electricity, and thus completely eliminates the use of chemicals, water and electricity and generates no liquid waste. When combined with the benefit of closed-loop recycling system that manufactures CTP plates of similar quality by reusing the main material, aluminum, this equates to reduction in CO2 emissions by approximately 390 tons per plant annually.

FUJIFILM GFX 50R (Gold)

In a bid to save resources and reduce packaging materials, the FUJIFILM GFX 50R, a medium format camera with industry-leading image quality for professional and amateur photographers, weighs 775g and is 16% lighter than the GFX 50S of the same series model. Overall, the product achieved, downsizing by about 8% and parts reduction by about 14%.

instax mini Link (Gold)

Approximately 20% smaller and more lightweight as well as having 40% less parts when compared to Fujifilm’s conventional models, smartphone printer instax mini Link leads the way in resourceful smartphone instant printing. The reuse of plastic waste materials in the manufacturing process has also had a significant impact on waste reduction and CO2 emissions.

Synapse® PACS (Silver)

As an industry-leading medical imaging and information management system, Synapse® PACS, offers significant resource, space and time saving to healthcare organizations. As just one example of approximately 650 installs across Europe, ASST Vimercate Hospital, a main customer and partner of Fujfilm Italia SpA, operates a high-tech and paperless structure due to the complete computerization of all its clinical-health processes thanks to the Synapse® platform. This means patient records can be easily managed at the patient’s bedside, or anywhere throughout the hospital.

www.fujifilm.eu