At the Xerox Premier Partner event in Madrid, keynote speakers and printers outlined their vision of the future to come.

At the Xerox Premier Partner event in Madrid, keynote speakers and printers outlined their vision of the future to come.

By Sabine Slaughter – PART I

Print in all its facets is still very much alive. However, as the world is changing at a rapid pace due to new digital offerings, so is print. It needs to adapt in order to stay the valuable medium that it has been for centuries. In fact, print is even an essential market participant in the whole global communications mix when and if it presents and places itself at the right spot(s). This is probably the most important message that participants of the Xerox Premier Partner event have been taking home with them.

Internet dating

Internet dating

As much as the Xerox Premier Partner event is a conference and an exhibition for premier partner companies, it is most of all a networking event where all participants, be it printers, suppliers or other market players come together to exchange their views, search and find peers and develop new relationships.

Relationships, that are paying off big time in some cases and whose initiation has been done via the Xerox Premier Partner website. One of such relationships that has been initiated by the requirement of a multinational print client to have a closer personal contact with the printer on a more local level is the example of The Gabriel Group in the US and Jubels NV from the Netherlands. When someone asks the CEOs how they got to know each other, they will answer truthfully: "Internet dating".

As strange as it sounds, it is exactly what happened when a large client from the Gabriel Group in St. Louis was asked by a client to provide a more personal service in Europe. Via the "matching" tool on the Xerox Premier Partner Global Network, Mike Peterson, CEO of the Gabriel Group, started the search for a partner from the Xerox Premier Partner Network that could fulfil the requirements his client asked for. The network provides a directory with over 500 leading graphic communications providers worldwide.

Initial contacts were made with the Dutch company Jubel NV, meetings conducted, work processes and quality tests done, and after the "chemistry was deemed right", the companies decided to jointly cater to the client whereby Jubel NV would locally fulfil orders the multinational client makes from Gabriel Group's web-to-print repository.

Quality tests established that Jubel NV's output quality was higher, due to its matte finish option on their Xerox iGen press. Mike Peterson, also an iGen press owner, whose company always wants to provide the best that is on offer, consequently upgraded to a Xerox iGen press offering the same finishing option that already was installed at Jubel NV. As both companies printed on Xerox iGen presses and used the XMPie software, only the necessary IT-integrations had to be established so that Jubel NV could access Gabriel Group's web to print system.

The print client was happy and sees it as a dramatic change that he can now speak to his printer at 9 am European time instead of having to wait till 3pm. As a result, the one million dollar account is now shared by the Premier Partner duo. Jeroen van Druenen, Director at Jubel NV adds: "You can build very strong relationships with members of the Premier Partners community. We work with partners regularly from Japan, Germany and the UK as well as the US. Some I seek them, some they seek me." And this is just one example of how membership in the Xerox Premier Partner Global Network benefits its participants that was presented by Jeroen van Druenen from Jubel NV and Mike Petersen from the Gabriel Group.

Matchmaking for business success

The Xerox Premier Partner Network offers its members tools via their website that enable each participant to "find their match" and enable co-operation, be it for expanding their services, reach or just to cater to certain client requirements. Above is just one of the many successful examples that Xerox users have initiated and which pays well for both partners. As member of the Xerox Premier Partner Network the members can search in the global directory for the exact services or business profiles of companies that cater to their requirements.

But this is not all: Apart from partner search, the Xerox Premier Partners Portal also offers industry news and reports, the premier insights newsletter, business building tools, online marketing, webinars and events as well as the Xerox University.

Participants in this network are not restricted to business owners, production managers, prepress managers as well as iGen operators will also find a host of useful information when their company signs up to the Xerox Premier Partner Network. All these services help the participating printers to enhance their business performance and cater better to their clients.

The new Xerox Versant 2100

The new Xerox Versant 2100

Not to be missed has been the new Xerox Versant 2100 press, a xerographic cut sheet machine in the exhibition area. The press uses Xerox EA Low Melt Dry Ink featuring small consistent particles and a new low gloss formulation thus resulting in an offset like finish as the company states. An additional advantage is the lower power requirement for the fusing process for a variety of stocks. Able to print on media up to 350 gsm the press is designed for fast turnaround jobs and offers lots of automation features that enable printers to act more competitively in the marketplace.

Where is the market leading us?

Or: Where are we leading the market – this has been the topic of Jim Hamilton's presentation.

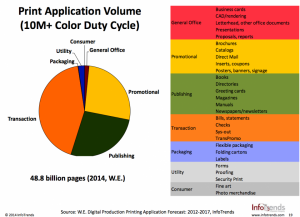

The group director from Infotrends outlined the different markets print nowadays engages in.

Those are:

• graphic communication

• packaging

• decorative

• functional.

All of these markets that belong to the production printing landscape have different requirements that need to be catered to as well but can nowadays already catered to with digital printing.

All of these markets that belong to the production printing landscape have different requirements that need to be catered to as well but can nowadays already catered to with digital printing.

When looking at the production colour digital market one can register that the entry level production printing side is nowadays nearly exclusively catered to by MFP devices (Multi-functional printers) that feature output speeds of up to 50-60 ppm. The light production sector for speeds between 50-150 imp is also accommodated by nearly exclusively MFPs. In the mid volume production market, that is characterised by speeds of 60-120 imp and requires duty cycles from 301,000 to 999,999 accordingly designed printers are predominantly.

Duty cycles of 1m to 10 m and output speeds from 150 to around 210 imp characterise the high volume production market that is served by printers only. the ultra high volume production (more than 10m duty cycle) is only accommodated by roll-fed printers. From the light production sectors upwards, demands for features such as a 5th station, 350 gsm support, long sheets, a rated speed, printing on all stocks, production class finishing as well as registration accuracy have evolved and are taken seriously by the manufacturers.

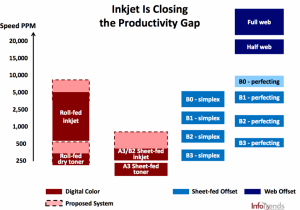

Currently the production colour digital market is kind of split in two sectors. Printers featuring speeds of less than 200ppm providing short-run, fast turnaround and are used for print on demand services are mostly cut sheet toner-based whereby average monthly volumes up to around 1m are reached and that require investments of up to $1m. The higher volume market from around 1m monthly volume features at least 600 dpi resolution at high speeds and is capable of handling very high volumes.

Those machines rare experiencing big success in transaction, books and direct mail and have a purchase price of at least $1m and are catered to by continuous feed inkjet technology. However, this might be changing as there is a "zone of disruption" where inkjet technology might break into: the area that features around 50,000 to 1m average monthly volume. New and continuous development of inkjet technology already enables new applications by featuring increased resolutions of 1,200 x 1,200 dpi and higher at high speeds; smaller drops that enable gray scale printing and adaptive content based drop generation.

New and continuous development of inkjet technology already enables new applications by featuring increased resolutions of 1,200 x 1,200 dpi and higher at high speeds; smaller drops that enable gray scale printing and adaptive content based drop generation.

The development of new line print heads can cater to any width for any application. Costs for printheads using MEMs technology are decreasing while the reliability of those print heads increases. Material science innovation for inks as well as functional fluids enables a host of new applications that can be accommodated by inkjet technology. And last but not least, new business models come to light as formerly proprietary systems become available for OEM partnerships for integrators. All these developments mean that inkjet technology can and will close the productivity gap that currently sill exists (see graphs).

When selecting a system, no matter whether it is digital inkjet or toner based or offset technology the main factors are cost and productivity.

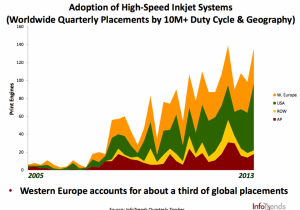

Adoption of high speed inkjet system featuring duty cycles of more than 10m has risen in the last years and is predicted to increase. While around 2006 most high speed roll fed printers have been black&white engines, the percentage of colour engines has risen steadily and now accounts for approximately half of the installed print engines. This can be attributed to inkjet technology and its possibilities.

It is predicted that a dramatic growth in colour engines will take place whereby a 13.7% CAGR between 2013 and 2018 is forecast. The amount of black and white engines is in decline and is predicted to be -6.4% CAGR for 2013-2018 in Western Europe and the US. While in 2013 US and Western European digital production colour volumes totalled about 265 bn impressions in 2013, the colour inkjet percentage accounted for 37% of the total volume. This is about to change as Jim Hamilton explained: "Infotrends expects the total volume to exceed 500 bn by 2018 whereby production colour inkjet will have a share of 59%. "This occurs despite the fact that digital color toner is also growing at a healthy rate", he added. Above numbers can be attributed to business transformations due to inkjet technology. Within the transaction sector the ability to have white paper on one side of the printer and an output of full colour jobs, partly with inline finishing eliminates pre-printed forms. Letters, inserts and envelopes can all be produced on the same web and full variable colour makes a big impact in the transpromotional market. In the area of direct mail and catalogues, 1:1 and segmented communication can and will be introduced, mail optimisation and the use of variable colour strengthens this market that is posed to be catered to by inkjet technology. Already started but by far not yet finished in terms of transition is the book and brochures sector. On demand printing, just in time manufacturing enable printers to act as a virtual document warehouse whereby inkjet printing is predicted to play the dominant role.

Within the transaction sector the ability to have white paper on one side of the printer and an output of full colour jobs, partly with inline finishing eliminates pre-printed forms. Letters, inserts and envelopes can all be produced on the same web and full variable colour makes a big impact in the transpromotional market. In the area of direct mail and catalogues, 1:1 and segmented communication can and will be introduced, mail optimisation and the use of variable colour strengthens this market that is posed to be catered to by inkjet technology. Already started but by far not yet finished in terms of transition is the book and brochures sector. On demand printing, just in time manufacturing enable printers to act as a virtual document warehouse whereby inkjet printing is predicted to play the dominant role.

Those business transformations require not only digital presses but also front-end and finishing developments. Automated order systems for just in time manufacturing and print on demand as well as capability to handle high volumes of data are just two of them. In addition, image systems for transactional applications are required. Within the finishing area coaters for direct mail; cutting, slitting, stacking devices for inline book finishing; selective perforation as well as roll wind and unwind machines, that preferably can be connected inline are further needs that cater to streamlined production. "High speed inkjet systems are producing high volume for transaction, direct mail, and books, not because they are cheaper than offset, but because they can do something that offset cannot do", summarises Jim Hamilton.

There are still lots of growth opportunities in the digital production print market. Greater speed, quality, efficiency, sustainability and customer service paired with continuous investments in technology, business processes and sales and marketing will result in new leaders that offer and employ new services, products, customers and business models.

Every printer or print service provider will have to find his model for business transition whereby technologies, workflow automation and products and services are interlinked. Apart from cost and productivity print requirements such as colour and other effects, formats, substrates, workflow automation and process improvement need to be considered in order to achieve a future-proof environment.

Client demands for shorter runs, quick turnarounds, proofs/prototypes, personalisation, just in time manufacturing, and document factory services need to be catered to by for example templates document creation, automated job ticketing, w2p job submitting, automated job queues, integrated finishing as well as job tracking and reporting.

Above means that printers should be investing in automation and innovation. They should be considering the use of digital production print to add new applications and/or transform their business models whereby also creation of unique rather than mass manufactured content is to be given a thought. Before transitioning the costs of front-end systems and finishing requirements in the overall workflow need to be taken into account as well as the new press that printers want to acquire as the right infrastructure will ensure seamless processes and operational efficiency.

To be continued...