The Hunkeler Innovationdays (HID) 2025, held from February 24–27 in Lucerne, Switzerland, was a landmark event for the printing industry. It marked the second official joint trade show for the Postpress Alliance following drupa 2024. Founded in 2019, the Postpress Alliance is a collaborative initiative between MBO and H+H, joined by other key players in the postpress sector, including Hohner, BOGRAMA, baumannperfecta, and Wohlenberg.

The Hunkeler Innovationdays (HID) 2025, held from February 24–27 in Lucerne, Switzerland, was a landmark event for the printing industry. It marked the second official joint trade show for the Postpress Alliance following drupa 2024. Founded in 2019, the Postpress Alliance is a collaborative initiative between MBO and H+H, joined by other key players in the postpress sector, including Hohner, BOGRAMA, baumannperfecta, and Wohlenberg.

Their participation at HID 2025 was a major highlight, showcasing a unified approach to delivering cost-effective, automated, and high-performance solutions for the postpress market.

For MBO and H+H Komori Group, HID 2025 provided the perfect platform to present their cutting-edge solutions in postpress processing. The event’s theme—product reliability and cost-effectiveness, driven by automated cross-process product solutions with open interfaces—aligned perfectly with the collaborative spirit of the Postpress Alliance, which aimed to redefine how automation and integration can enhance postpress workflows and production efficiency.

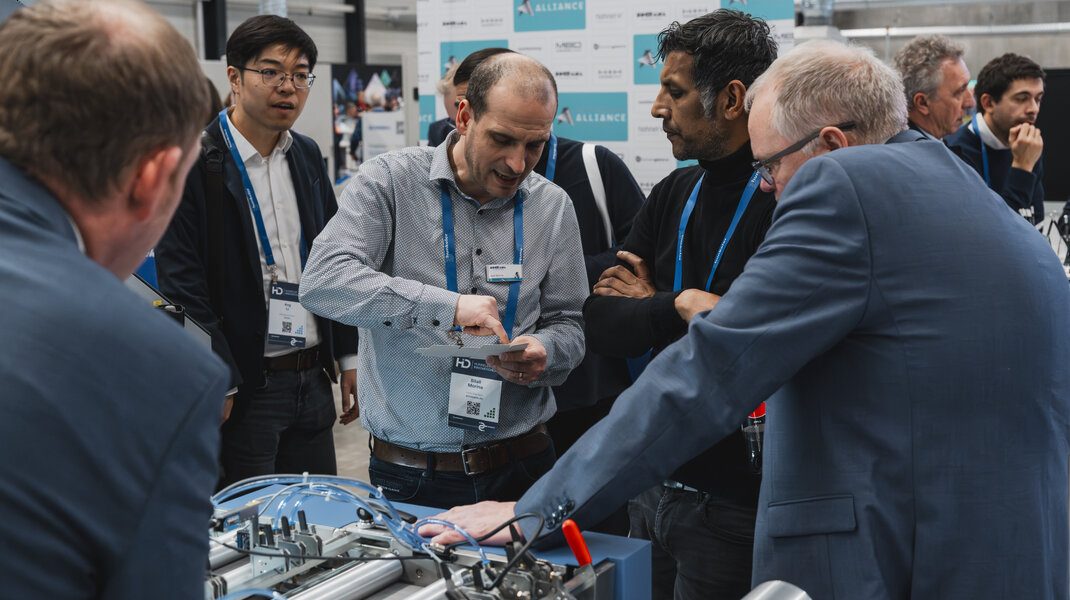

In addition to showcasing these solutions, the 15th Hunkeler Innovationdays emphasized the central role of networking in the printing industry, with the motto "CONNECT" taking centre stage. This motto provided a distinct and memorable experience for participants, highlighting the value of connections between companies, technologies, and people in driving the future of the printing sector. The Postpress Alliance’s participation, with its focus on integration and collaboration, aligned perfectly with this theme, reinforcing the importance of forming partnerships and sharing knowledge to push the industry forward.

Postpress Alliance: A Collaborative Force

The Postpress Alliance was one of the standout features of HID 2025, representing the collaborative efforts of MBO, H+H, Hohner, BOGRAMA, baumannperfecta, and Wohlenberg. This strategic partnership highlighted how combining each company’s specialized technologies can create an integrated, highly automated, and cost-effective workflow in the postpress environment.

Attendees were able to witness the power of collaboration as the Postpress Alliance demonstrated a wide array of solutions aimed at enhancing productivity, minimizing downtime, and optimizing postpress processes. The motto for HID 2025—“Together stronger and more innovative”—resonated with the spirit of the alliance, which sought to bring innovative, open-interface solutions to the forefront of the postpress industry.

Highlights from the Postpress Alliance Booth at HID 2025

H+H M9 with MBO Unwinder UW23 & SVC23

A central feature at the Postpress Alliance booth was the H+H M9 system, integrated with the MBO Unwinder UW23 and SVC23. This solution provided a glimpse into the future of small-format digital finishing, with the system designed to process roll-fed material in the most cost-effective manner. The M9 system proved its worth in its ability to efficiently handle even the smallest formats while ensuring smooth material handling and precision cutting.

The system demonstrated the core theme of HID 2025—how automation and integration between systems can provide enhanced efficiency and reliability. By using the M9 along with MBO’s advanced unwinder and cutter, the system enabled quick, seamless operations with reduced manual intervention, making it an ideal solution for high-volume digital finishing.

Digifinisher HHS-Futura by Hohner with MBO UW23 Unwinder

Another key attraction was the Hohner Digifinisher HHS-Futura, showcased in roll-fed mode alongside the MBO UW23 unwinder, SVC525C cross cutter, and folding machine. This setup demonstrated selective finishing capabilities, including variable page numbers and variable cutting thickness, essential features for the flexible demands of modern digital print workflows.

The Hohner system, integrated with MBO’s unwinder and cross-cutter, showcased the power of automation in achieving highly customizable finishes without sacrificing efficiency. The inclusion of the MBO CoBo-Stack 30i robot was a highlight, as it demonstrated how collaborative robots could autonomously handle finished products, further reducing manual labour and streamlining the postpress process.

This configuration underlined the importance of flexibility and automation in postpress systems, providing an ideal solution for those looking to enhance product variety while maintaining operational efficiency.

BOGRAMA BSR 550 Basic – Rotary Die-Cutting Technology

The BOGRAMA BSR 550 Basic was another notable system at the booth, showcasing the potential of rotary die-cutting technology. Known for its cost-effectiveness, nick-free die-cutting, and inline stripping, the BSR 550 Basic attracted significant attention for its ability to produce intricate designs with minimal setup time and high precision.

The system’s flexibility made it suitable for a wide range of print applications, including labels, packaging, and promotional materials. Its ability to achieve short makeready times and maintain high quality standards in die-cutting impressed visitors, demonstrating how BOGRAMA’s technology can deliver significant time and cost savings while ensuring flawless output.

baumannperfectaBP 92 High-Speed Cutter

The baumannperfecta BP 92 high-speed cutter was another key feature of the Postpress Alliance booth. Designed specifically for small-format digital printing, the BP 92 cutter highlighted the ongoing push toward automation and precision in cutting operations. The system’s integration of barcode scanners and Straight 2 Cut technology enabled the automatic conversion of prepress data into cutting programs, which significantly reduced the risk of human error and improved cutting accuracy.

The BP 92’s ability to handle high volumes with speed and precision made it a standout solution for digital printers seeking to enhance their productivity and reduce production costs. Its seamless integration into automated workflows was a clear demonstration of how cutting-edge technologies can optimize operations and improve the bottom line.

Wohlenberg

Although Wohlenberg did not exhibit machinery onsite, its representatives were available for in-depth discussions on the latest advancements in perfect binding, providing visitors with valuable insights and opportunities to explore cutting-edge innovations in the industry.

www.komori.com