Italian Masserdotti Group again opts for Zünd digital cutting technology. By investing once more in a Zünd G3 cutter, this specialist in digital printing is able to substantially increase its routing capacity.

Italian Masserdotti Group again opts for Zünd digital cutting technology. By investing once more in a Zünd G3 cutter, this specialist in digital printing is able to substantially increase its routing capacity.

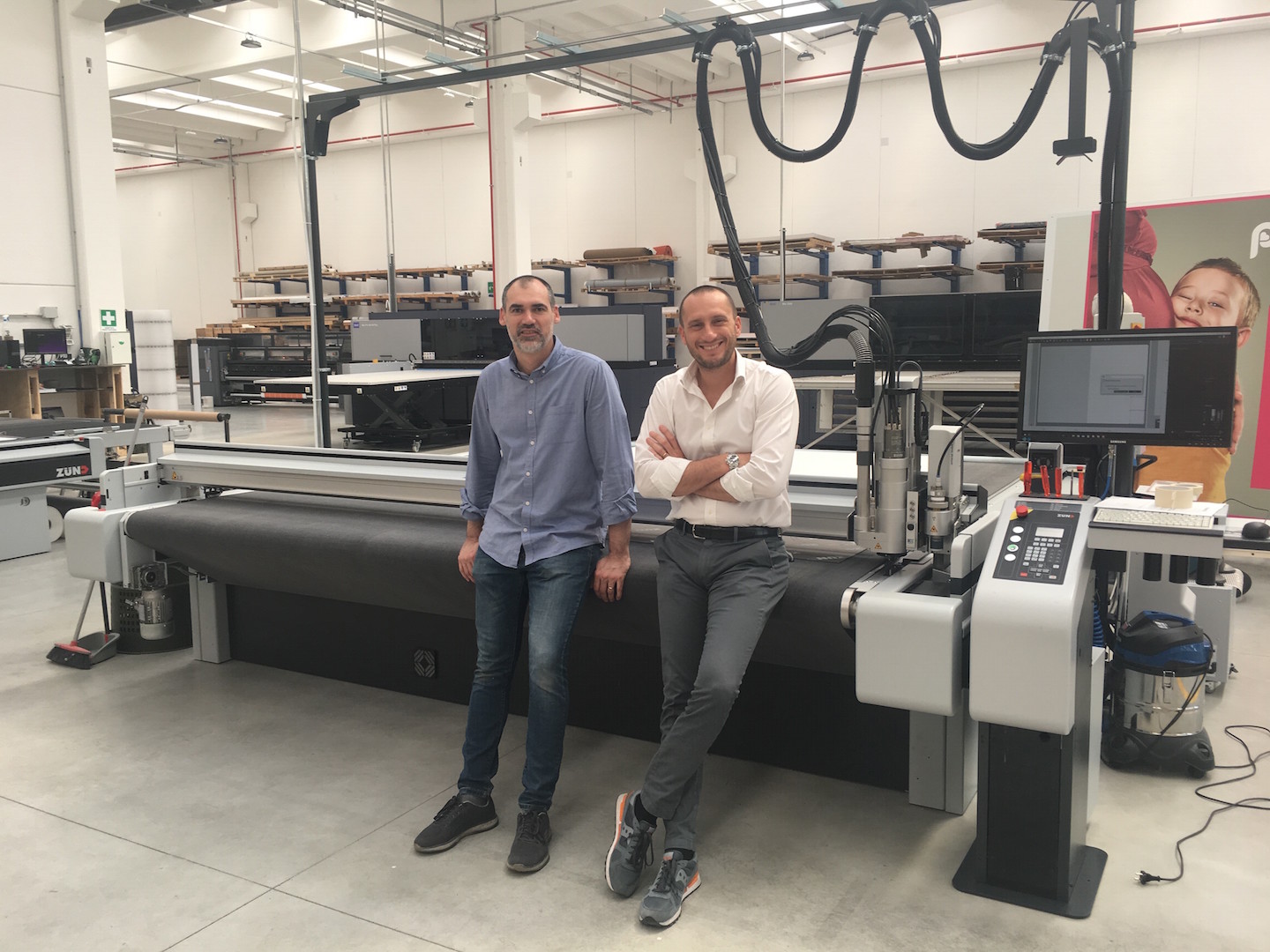

Equipped with «little technology but all the more imagination and creativity», the company that began as an automotive repair shop 50 years ago has established a reputation in visual communication that reaches far beyond the nation's borders. Now in its 2nd generation, Masserdotti is led by Alberto Masserdotti and has approximately 40 employees. It is located in Castel Mella, a Northern Italian town not far from Brescia. As early as back in the 90s, Masserdotti was known as a digital printing pioneer and, through continuous digitization of all its production processes, has managed to create new business opportunities along the way. For the past ten years, the company has been successfully manufacturing goods for the interior design market. It was an almost foregone conclusion that it would also expand its product line into digital signage, which it started doing in 2011.

The latest chapter in the company's history began in spring 2018 with the opening of a new production facility. A 10,000m2 space accommodates all the latest manufacturing technologies. In the past two years, this also included a Zünd G3 cutter for digital finishing which is now in operation three shifts per day. In the fall of 2017, Masserdotti added another Zünd G3 and at the same time also invested in a 3.6 kW RM-L Router Module. This addition brought with it a significant expansion in performance and flexibility for applications involving tough materials such as acrylics and wood. Comments Alberto Masserdotti: «Whenever we are about to make an investment, we want to make sure the production equipment we are considering easily integrates in our existing workflow and helps increase our quality levels. Zünd's digital cutting systems pass these tests with flying colors». By opting for the automatic router bit changer ARC, Masserdotti also continues its mission to further automate every aspect of production. From its investments in Zünd cutting systems, Masserdotti derives yet another benefit: «We are continually expanding our material palette. Zünd cutters allow us to use one machine for processing anything from polyester fabrics to PVC and all manner of rigid materials.»