In a world where the environmental pressure and circular economy are major priorities for brand owners and challenges for converters, BOBST provides the proven solution with PECVD SiOx.

In a world where the environmental pressure and circular economy are major priorities for brand owners and challenges for converters, BOBST provides the proven solution with PECVD SiOx.

The BOBST PECVD SiOx Solution produces high barrier film with a high degree of transparency which is both retortable and microwavable. SiOx coated substrates present less problems during the conversion process than other transparent barrier films, as well as being recyclable and FDA approved making them an ideal choice for converters looking to contribute to a circular economy.

BOBST PECVD Process

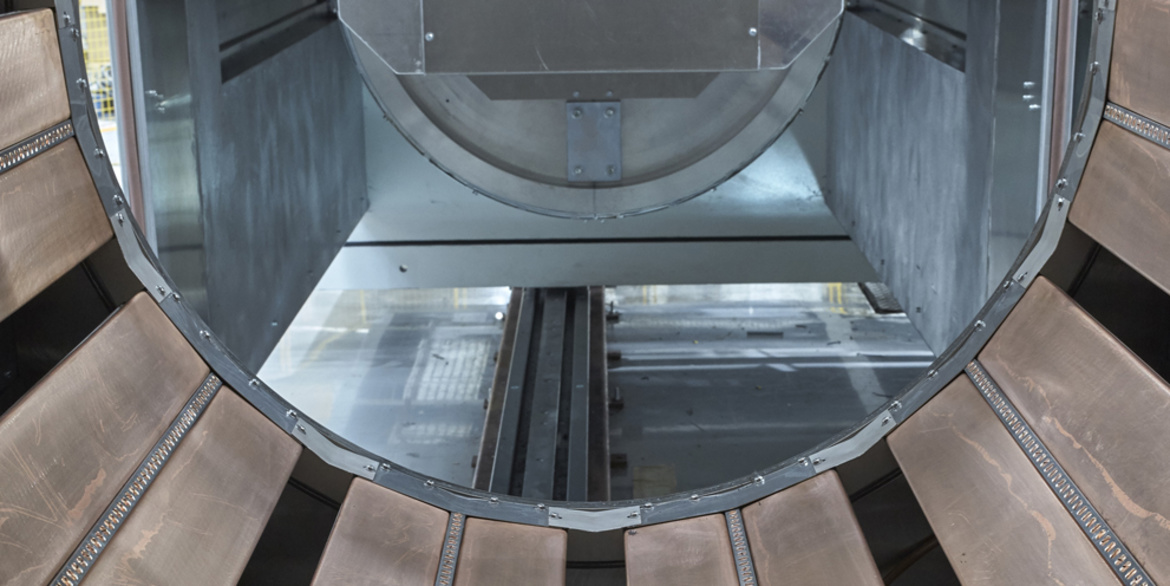

The PECVD process used to produce the SiOx coated film is cost effective and commercialised by BOBST, as well as being operator independent allowing for production of consistent high quality film. The process incorporates the use of a silicon based monomer (HMDSO) which is deposited on to the substrate within a low temperature plasma environment. The monomer and process gasses (He, O2 and Ar) are introduced into the vacuum chamber via a form of gas bar; the gas bar ensures even process gas distribution across the width of the machine and therefore a uniform coating of SiOx .

Films created during the PECVD process are very thin and in order to achieve good barrier levels the quality of the coating needs to be optimized. As a result of the AC power supply there is a physical bombardment of ions and electrons towards the process drum which creates densification of Silicon Oxide on to the film providing more of a resistance to oxygen and water permeation.

The temperatures used throughout the process are low which makes the process ideal for heat sensitive and thin gauge substrates such as BOPP and CPP.

Excellent Oxygen and Water Barrier

The SiOx coated film has excellent oxygen and water barrier levels of around 2cc/m2/day (OTR) and around 2gm/m2/day (WVTR) on PET and retains high levels even when subjected to a Stretch-durability test; the film can handle a high level of strain and stretch maintaining barrier at strain levels of <4%. The flex durability of the film as measured by the aggressive Gelbo test can be seen in the two graphs below.

The results of these tests show that the SiOx coating can withstand the various stresses and strains during conversion processes without there being a significant deterioration in barrier levels making it the most flexible and forgiving inorganic transparent barrier film.

High Adhesion for Retort Applications

The BOBST SiOx process has excellent adhesion properties for both dry and wet applications, adhesion values of >4N/15mm can be achieved. The excellent adhesion properties mean the coating is successfully used in many retort applications in the market.

BOBST Integrated Conversion Solution

The BOBST PECVD SiOx process is available on the BOBST K6 platform, this machine incorporates two coating drums and is available together with the CO 1000 coating machine from Bobst Italia as an Integrated SiOx Conversion Solution; the solution involves a top coat being applied to the SiOx film which improves printability and enhances barrier guaranteeing the best barrier performance over a long period.