Leading Danish independent trade shop reprocentret A/S has invested in a fully integrated flexo plate making solution from Esko to deliver enhanced quality and consistency for its customers.

Leading Danish independent trade shop reprocentret A/S has invested in a fully integrated flexo plate making solution from Esko to deliver enhanced quality and consistency for its customers.

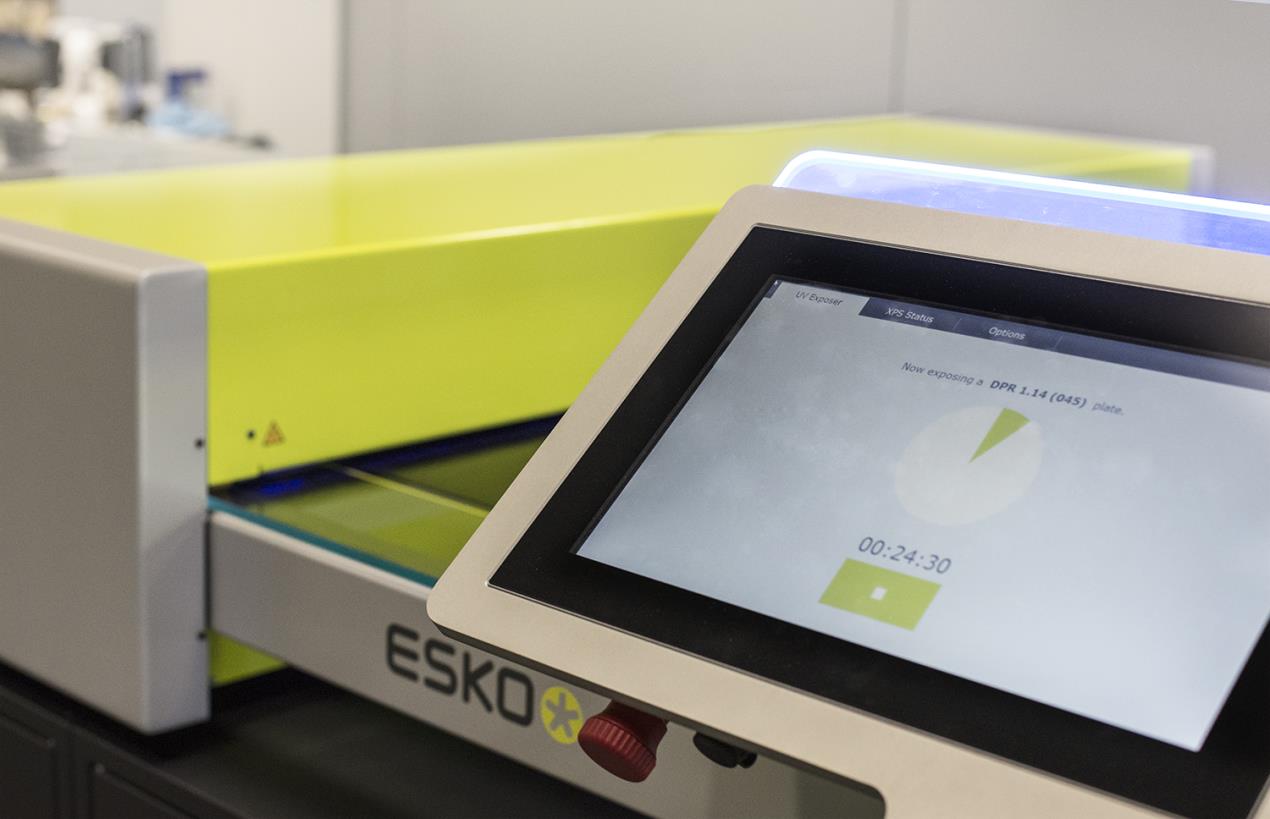

reprocentret_logoThe specialist in plate making for mid and wide web flexible packaging, labels and brand owner services has installed an Esko CDI Crystal 5080 XPS, the fourth such machine at its facility in Vejle, Denmark. The new installation continues the company’s long-standing relationship with Esko, the leading developer of integrated hardware and software solutions for the global packaging industry.

“reprocentret is one of the largest independent trade shops in Scandinavia,” said James Mason, Esko Regional Business Director, EMEA North. “Having enjoyed a successful relationship for many years, we’re delighted to further extend our relationship with the installation of a new CDI Crystal XPS. The flexo imager and integrated exposure unit really complements the company’s existing set up, which now includes a completely integrated workflow featuring the full Esko portfolio for editing, workflow rip, collaboration and imaging.”

CDI Crystal 5080 XPSThe combination of the CDI Crystal flexo imager with the XPS Crystal exposing unit, incorporating UV main and back exposure, offers a flexo platemaking workflow that delivers outstanding plate quality and consistency to boost print performance.

“reprocentret will immediately benefit from significant quality and efficiency gains from the CDI Crystal XPS, as it uses LEDs that require no warm-up time and emit even light to deliver highly consistent plate exposure,” said James. “The integrated unit also reduces manual steps by 50%, operator input time is slashed by more than 70%, and errors are reduced by up to 50%, meaning a significant decrease in plate material, and importantly time, being wasted.

“With this type of integrated workflow, the plate making process is much less complex and has significantly fewer steps while delivering optimum quality,” added James.

Thomas Christensen, CEO of reprocentret, said this consistency was one of the key drivers behind the latest Esko CDI Crystal w PlateHandlerinvestment. “The combination of the Esko CDI Crystal 5080 with the XPS UV LED exposure unit provides the highest levels of consistency and quality on the market,” he said. “This helps us not only achieve our goals in terms of delivering results of the highest standard, but also underlines our position in leading the way in using the latest technology in Denmark. Indeed, we are proud to be the first company in the country with this integrated setup.

“Our relationship with Esko spans a number of years and we are delighted to be continuing that success with this latest addition to our state of the art facilities,” he said.

The sale was completed by Artwork Systems Nordic A/S, a Danish channel partner of Esko. Owner Paw Meng Mortensen said of the deal: “The integration of Esko technology at the site means reprocentret has complete control of its plate production. We were excited to install the first Esko CDI Crystal 5080 XPS in Denmark at reprocentret, which will boost the company’s customer satisfaction by delivering enhanced plate quality and consistency.”

www.esko.com